Production of lithium compounds directly from lithium containing brines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

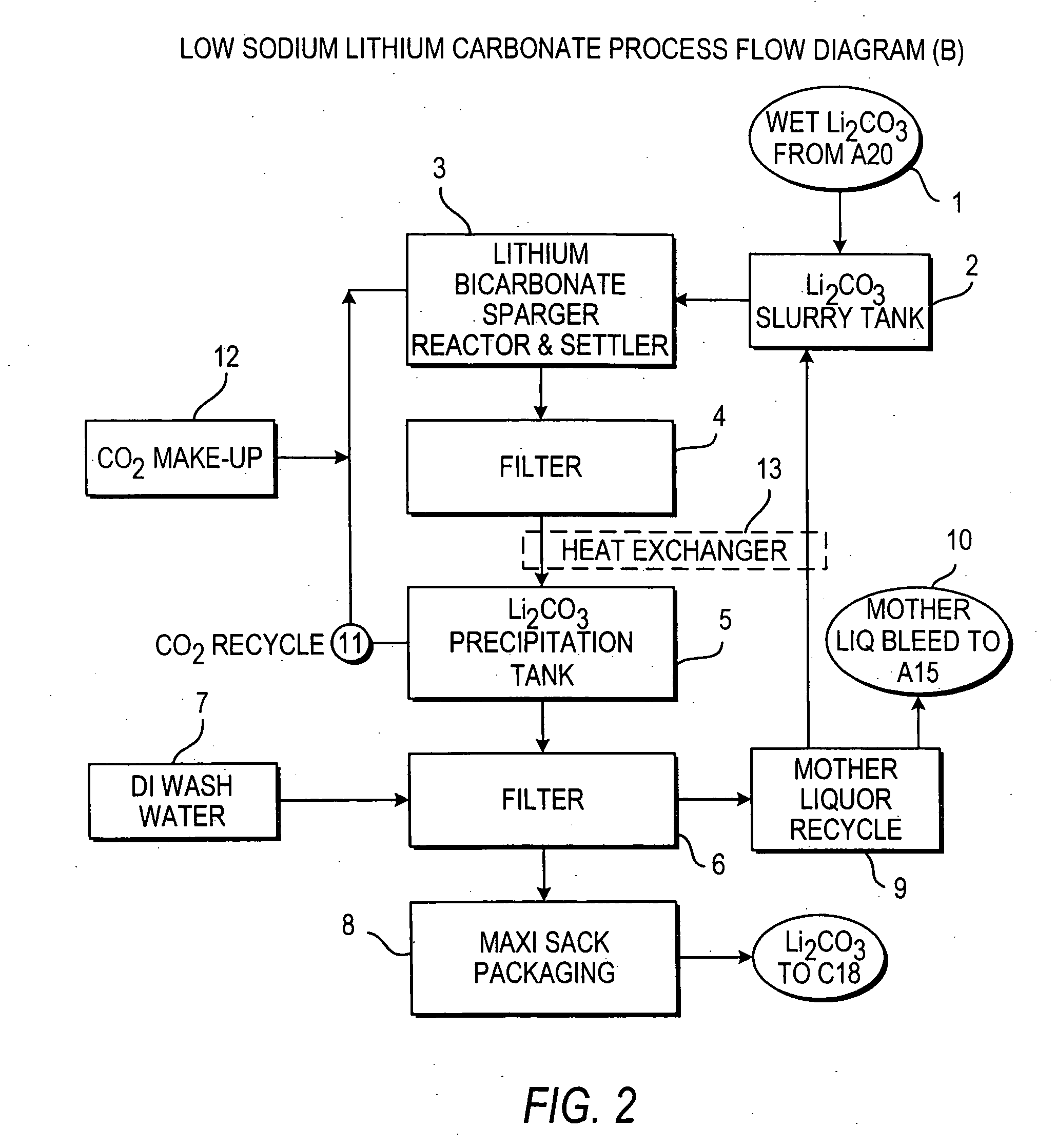

[0149] Preparing Low Sodium Lithium Carbonate

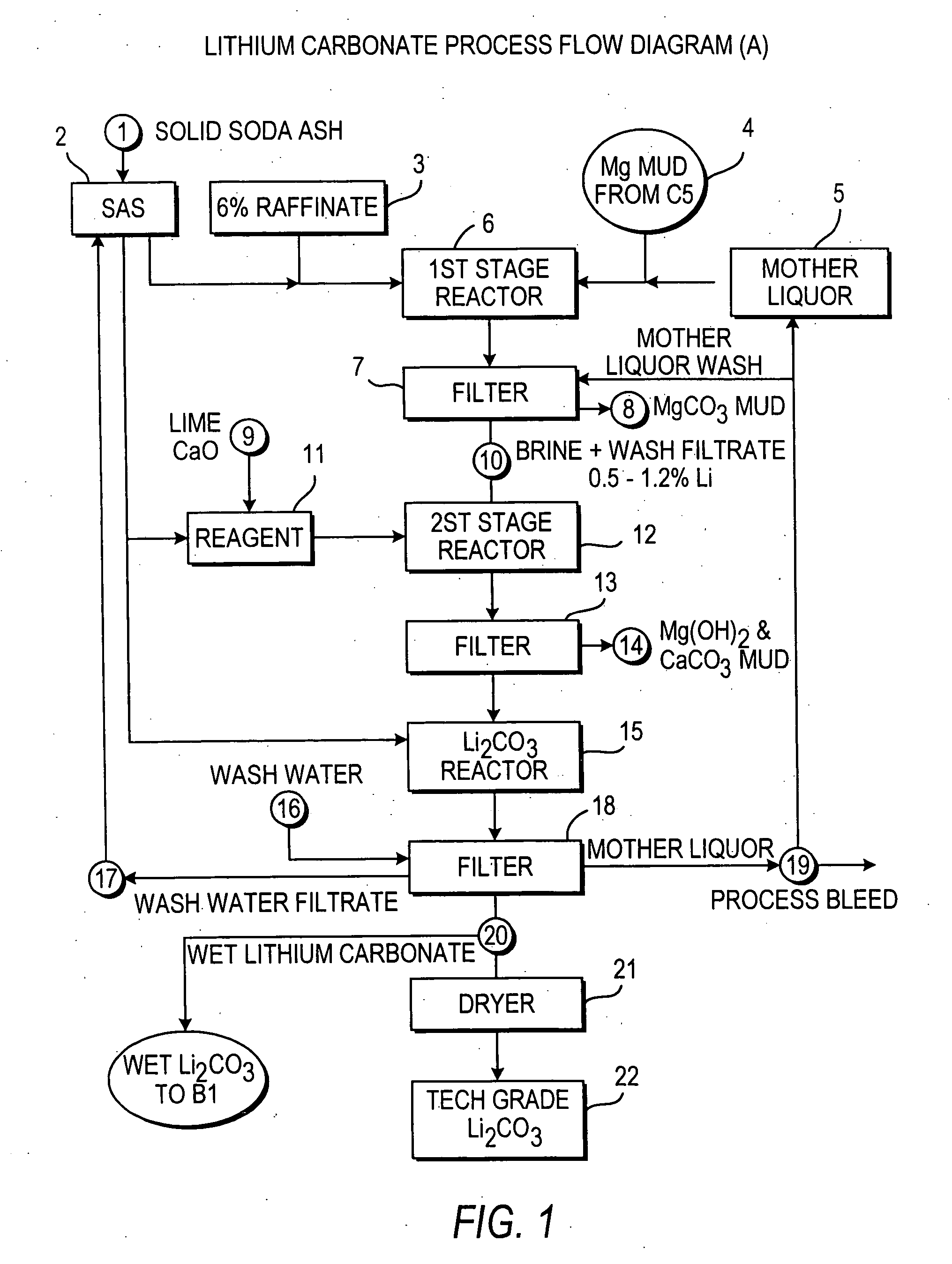

[0150] To a concentrated brine containing 6.19% Li, 1.51% Mg, 0.179% Na, 0.026% K, 0.056% Ca, 0.002% SO4, 0.0003% B, and 36% Cl, recycled mother liquor containing 0.14% Li, 8.26% Na, 0.18% SO4, 12.37% Cl, and 0.58% CO3 was added at a temperature of 70° C. Enough mother liquor was added to form a solution containing 1% Li. This also precipitated most of the magnesium as magnesium carbonate and basic magnesium carbonate. The solution was filtered to remove the precipitated magnesium. The magnesium remaining in solution was removed by adding a limed soda ash reagent which also reduced calcium as an insoluble calcium carbonate solid. The resultant purified brine was filtered and contained 1% Li, 0.0002% Mg, 0.0024% Ca, 6.9% Na, 15.5% Cl. A soda ash solution was prepared using lithium carbonate wash water filtrate and added to the purified brine. The lithium carbonate crystals were filtered and subsequently washed with hot de-ionized or disti...

example 2

[0155] Preparing. Ultra High Purity Lithium Carbonate

[0156] Ultra high purity lithium carbonate was prepared as described above in the same equipment to which was added an ion exchanger between the filter and the heat exchanger. The ion exchange column contains Rohm and Haas, Amberlite IRC-718. The purity of this product is listed in Table 6.

TABLE 6ULTRA HIGH PURITY LITHIUMCARBONATE (EXAMPLE 2)Wt %Li2CO3>99.995MgNaKCaSO4BClSiZnCrCuFeNiP

example 3

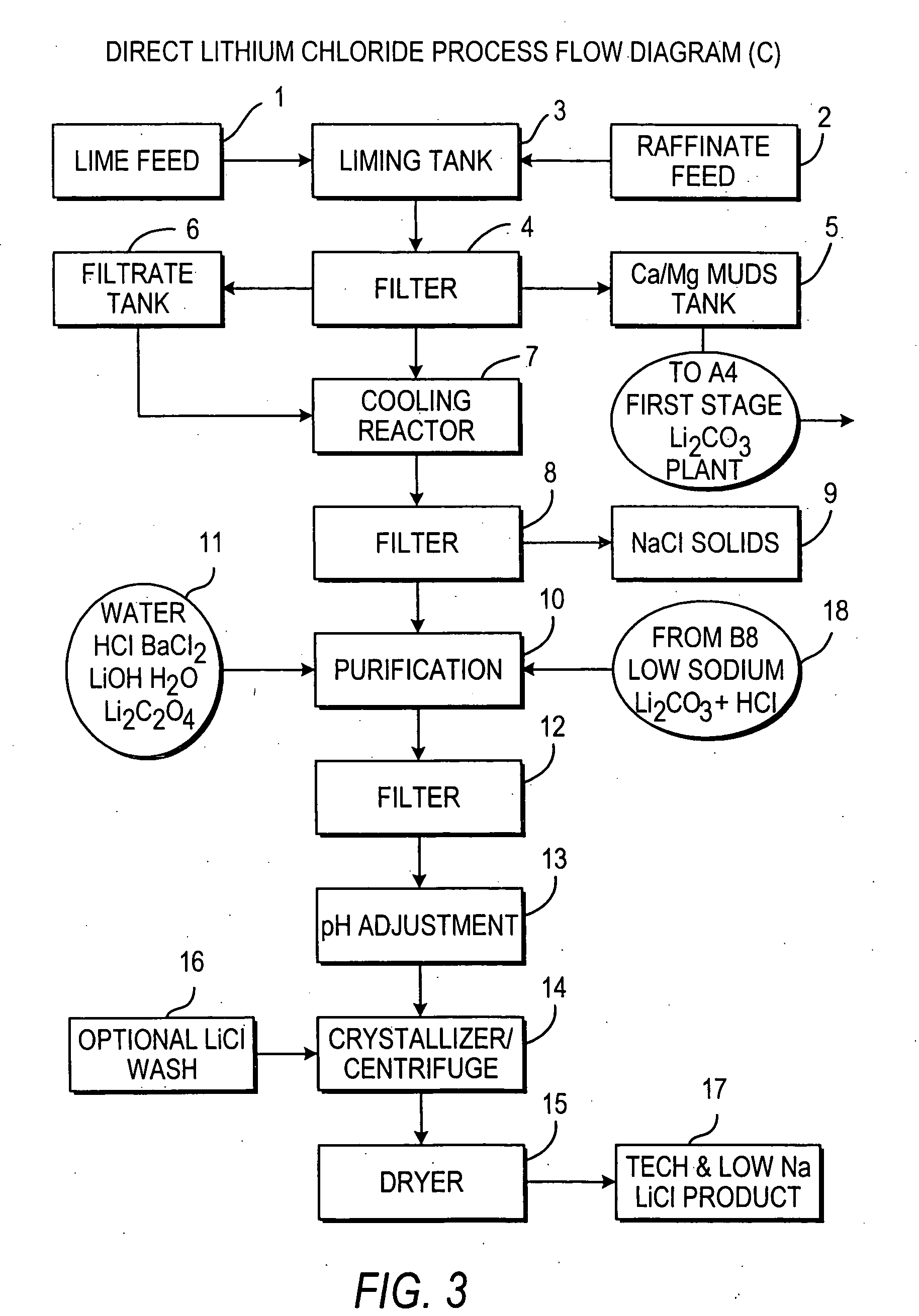

[0157] Preparing Low Sodium Lithium Chloride

[0158] Hydrochloric acid (35% conc.) containing less than 0.00015% sodium was reacted with lithium carbonate prepared in Example 1. The resulting solution was evaporated to crystallize lithium chloride. The lithium chloride was filtered from the evaporated solution and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com