Patents

Literature

42results about How to "Avoid excessive addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

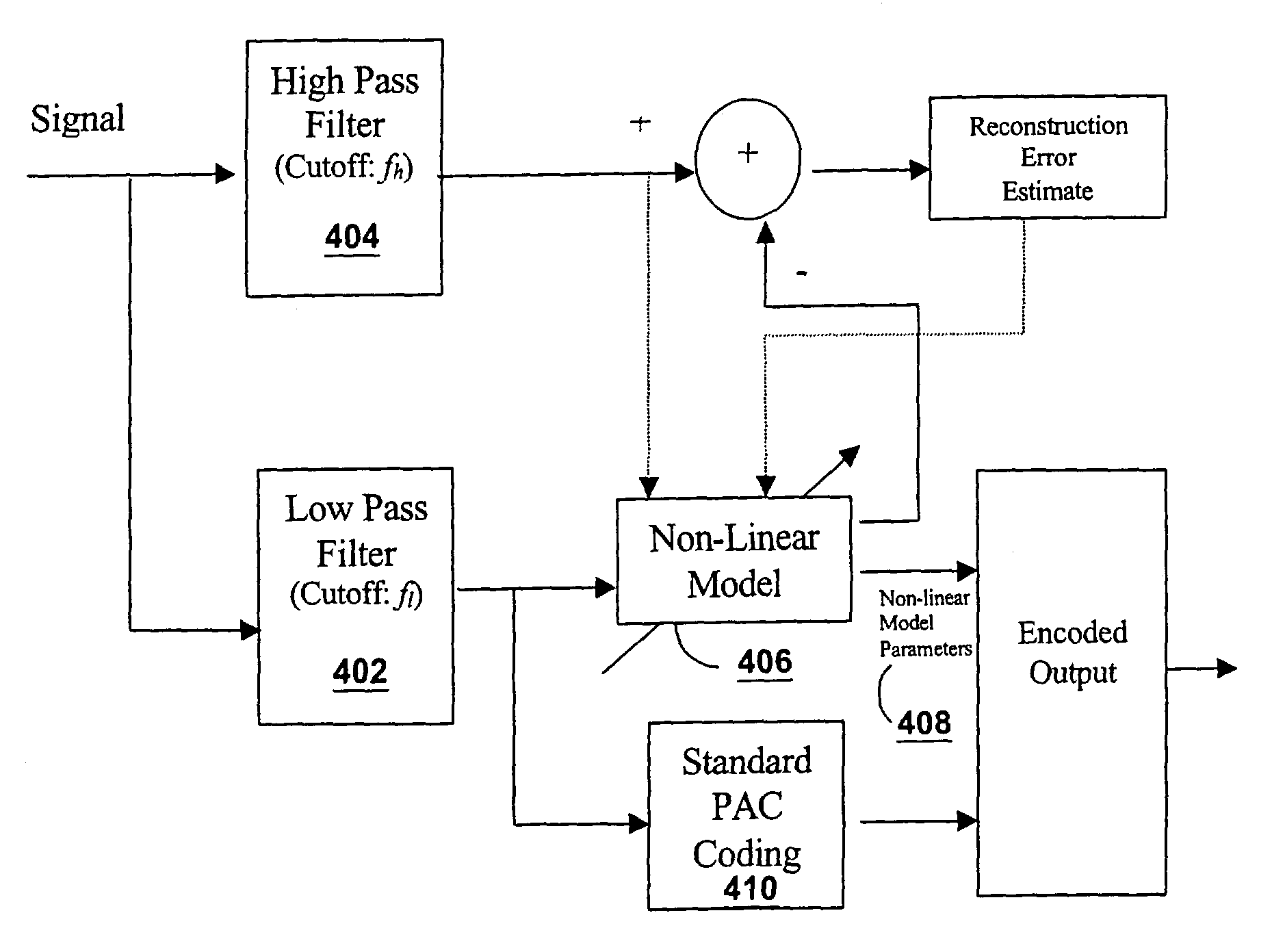

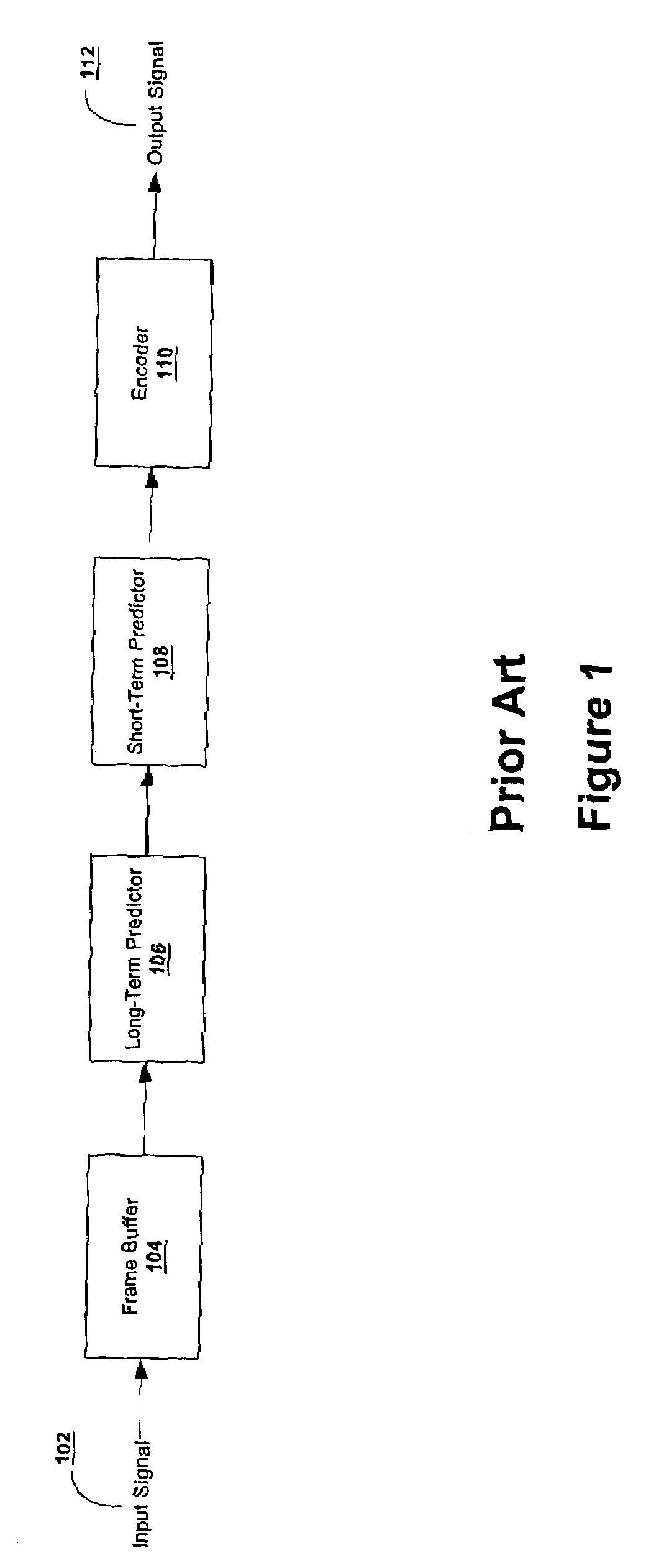

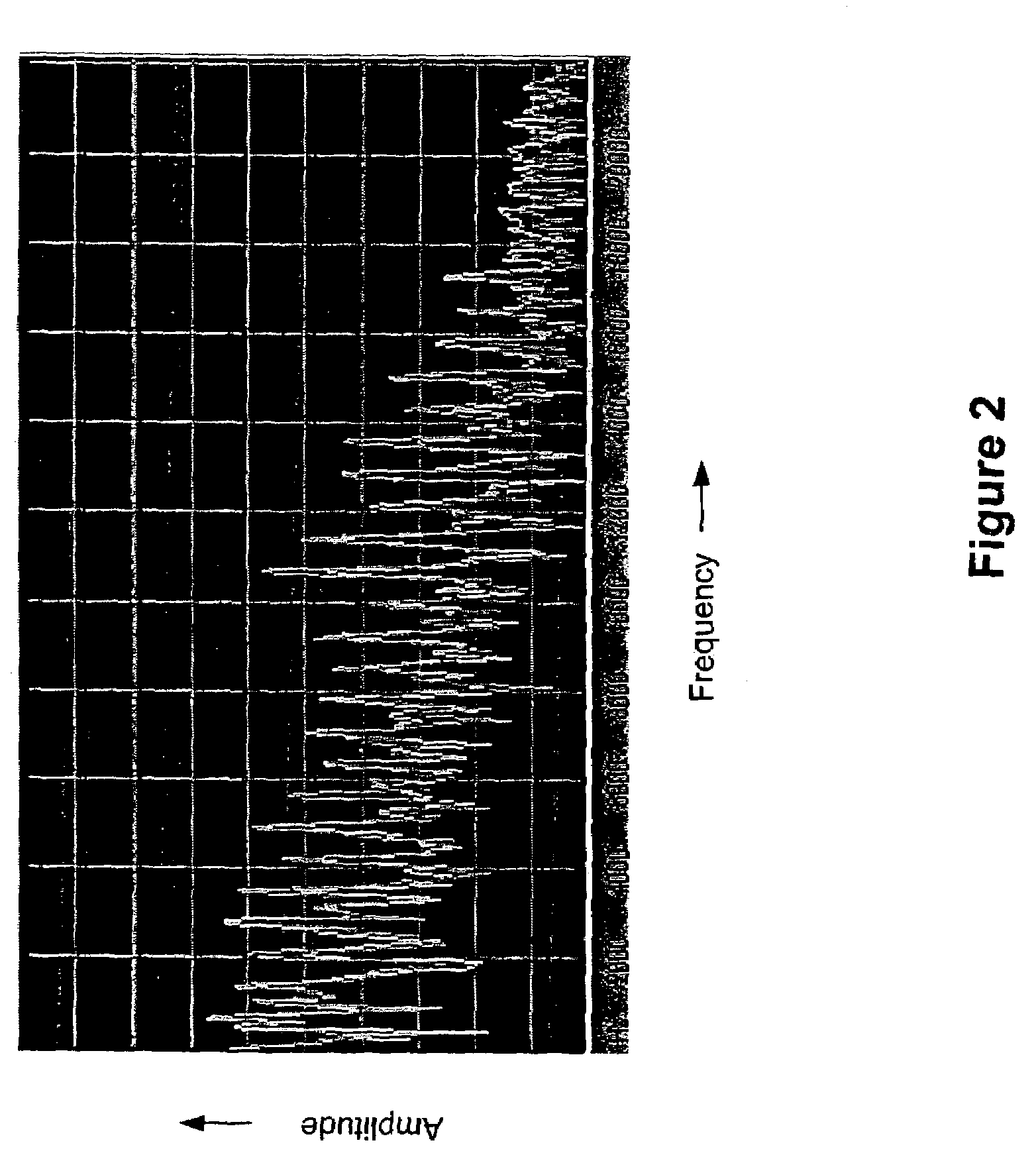

Efficient coding of high frequency signal information in a signal using a linear/non-linear prediction model based on a low pass baseband

An efficient coding scheme with higher audio bandwidth and / or better audio quality at lower bitrates, wherein the scheme eliminates long-term and short-term frequency domain correlation in a signal via frequency domain predictors. The coding scheme compresses information consisting of coded low frequency components as well as a parametric representation for the high frequency components based on a non-linear model. Additionally, by working on the frequency domain representations of the signal (such as the MDCT representation which is naturally available to a PAC encoder and decoder), low pass and high pass signal components are easily obtained by windowing the appropriate ranges of frequencies in the signal. Furthermore, the power functions of the signal are replaced by corresponding convolution functions of the same order.

Owner:IBIQUITY DIGITAL CORP

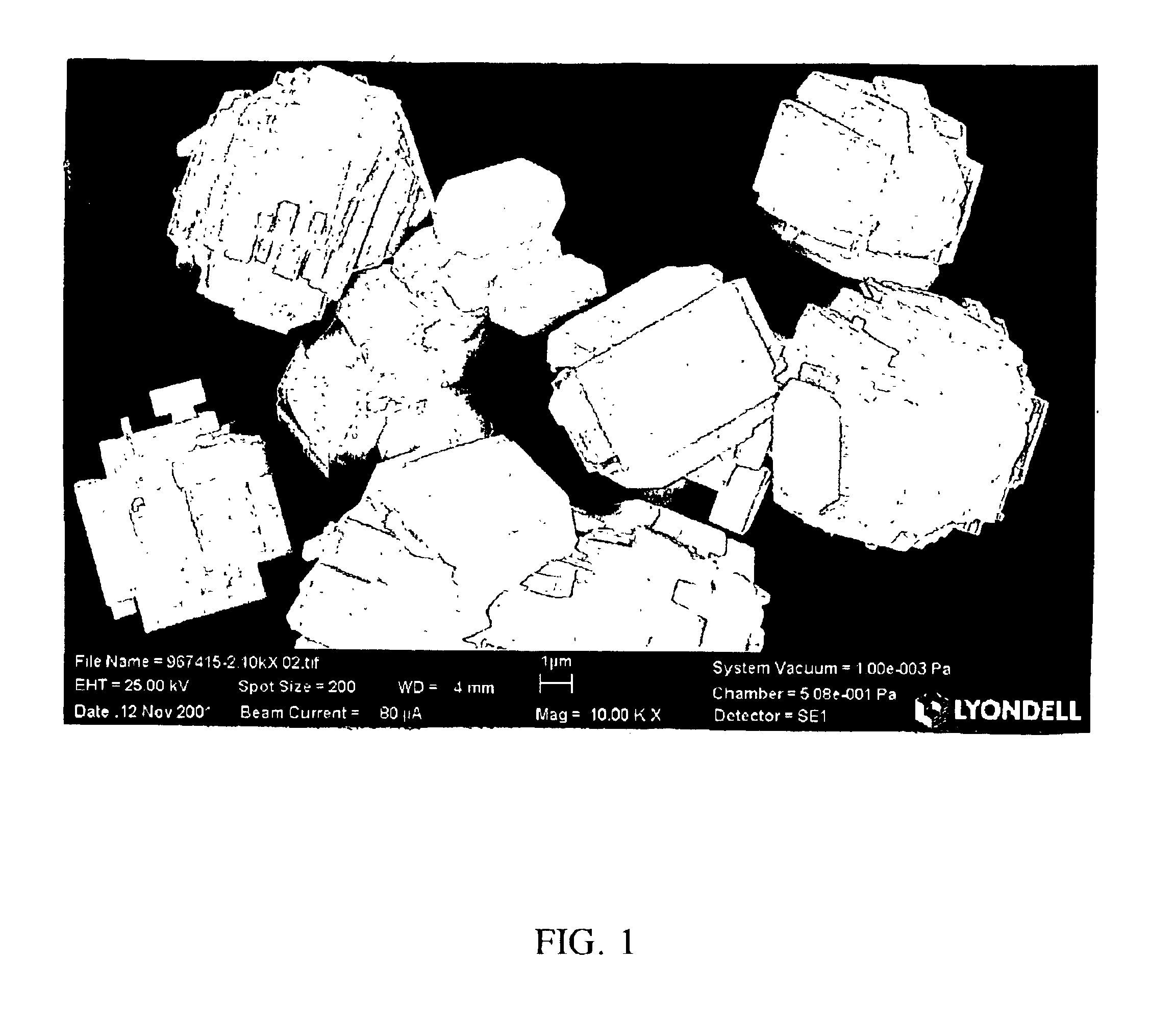

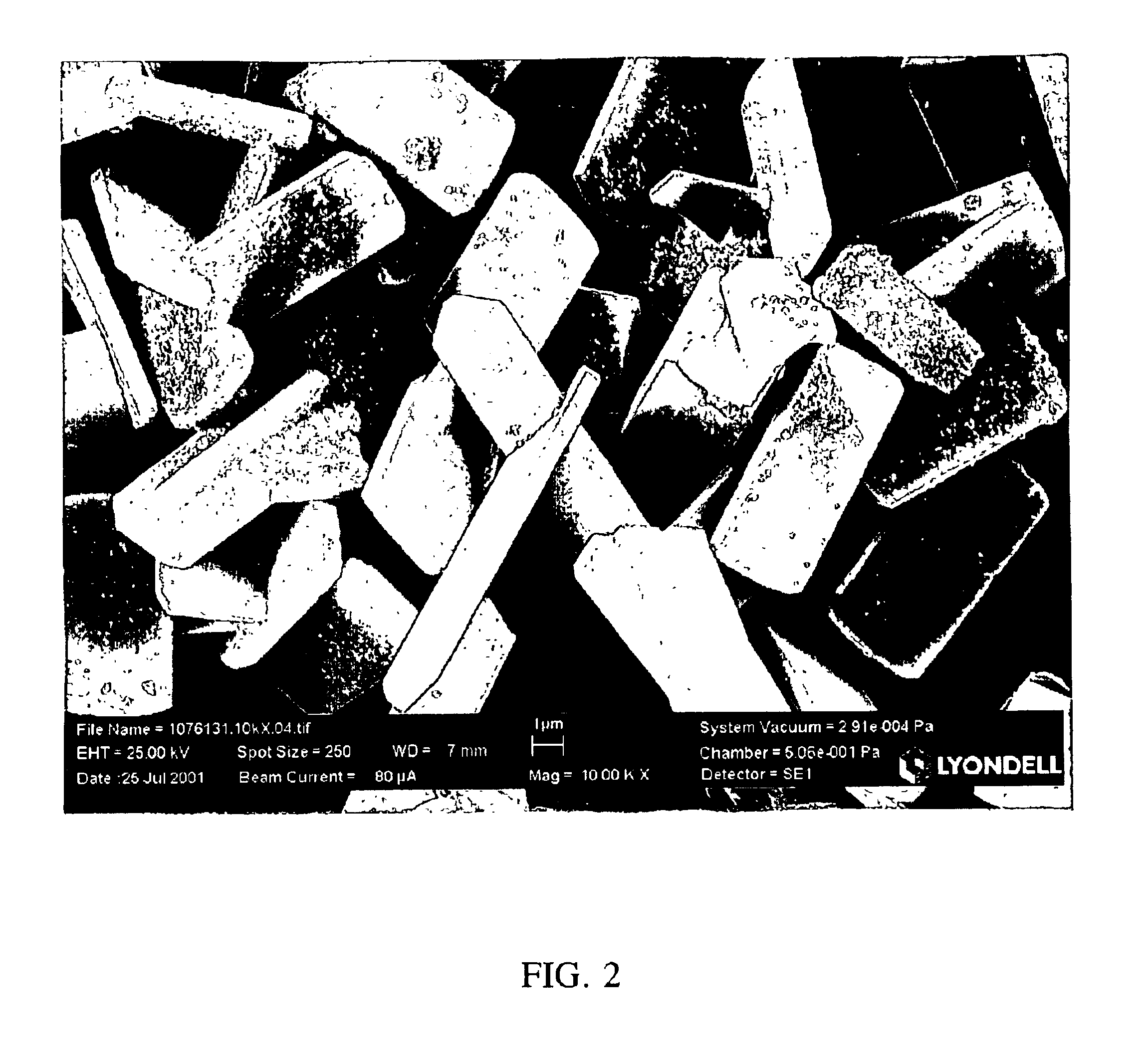

Process for direct oxidation of propylene to propylene oxide and large particle size titanium silicalite catalysts for use therein

InactiveUS6960671B2Avoid excessive additionOrganic chemistryMolecular sieve catalystsTitaniumSilicon dioxide

Large crystals of titanium silicalite or intergrowths of intergrown smaller crystals, having a mean particle size greater than 2 μm, have been found catalytically effective at commercially reasonable rates for the epoxidation of olefins in the presence of hydrogen peroxide. Crystals synthesized with a silica source having a low sodium content exhibit high levels of production and selectivity. The crystals have a low attrition rate and are easily filterable from a product stream.

Owner:LYONDELL CHEM TECH LP

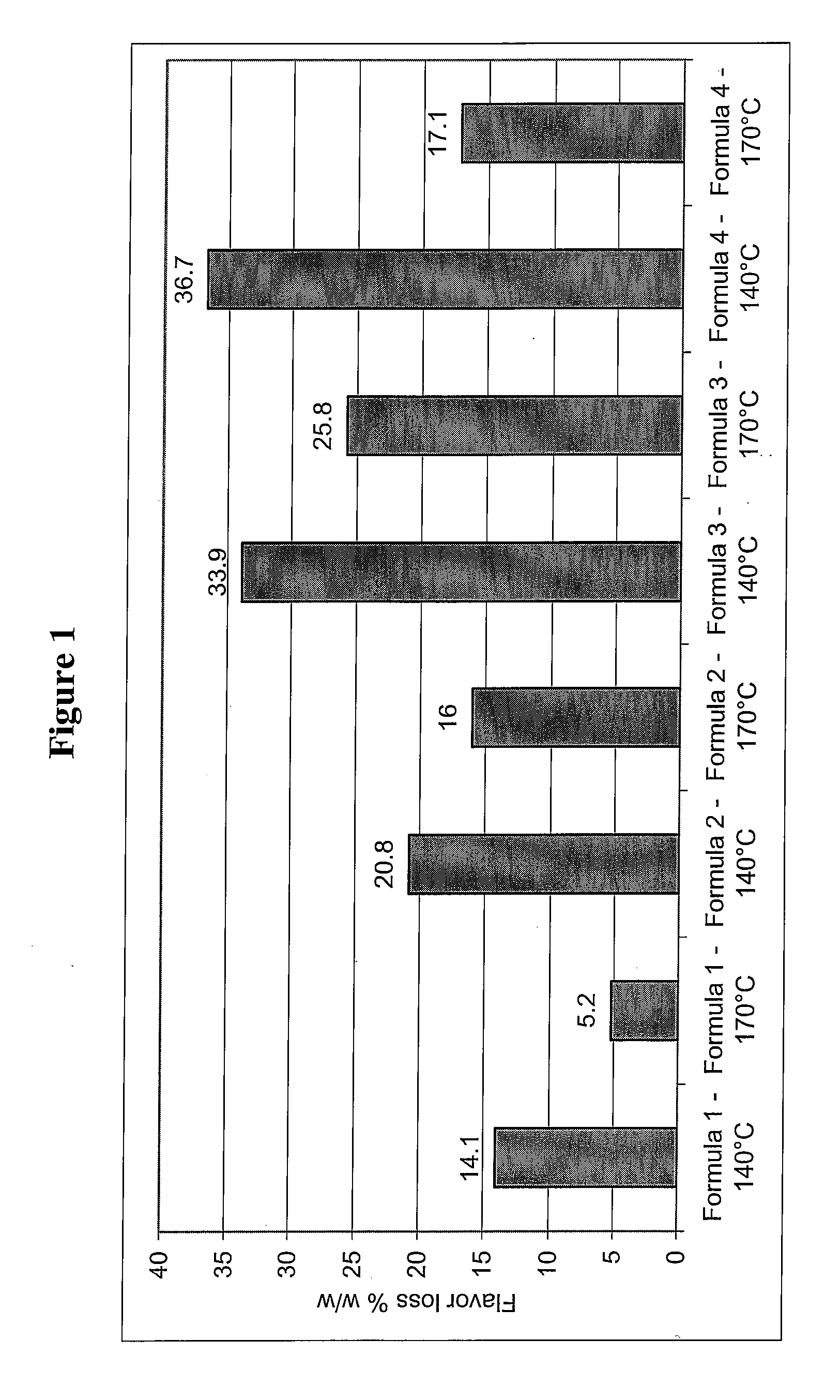

Flavor or Fragrance Capsules

InactiveUS20090047434A1Reduce lossesLoss of volatiles remained significantly lowerCosmetic preparationsToilet preparationsEmulsionAdditive ingredient

The present invention relates to capsules encapsulating a flavor or fragrance ingredient, the capsules being obtainable by a method in which an emulsion comprising the ingredient is dispersed in the form of drops in a spraying tower and exposed to a temperature in the range of 121 to 250° C. In the tower, a cloud of suspended powdering agent provides a coating and prevents the capsules from sticking together. The capsules have a high ingredient load of about 18-40 wt. % and a particle size in the range of 100 to 2000 μm. The method for obtaining the capsules has the advantage of substantially less loss of ingredient during drying compared to similar processes of the prior art.

Owner:FIRMENICH SA

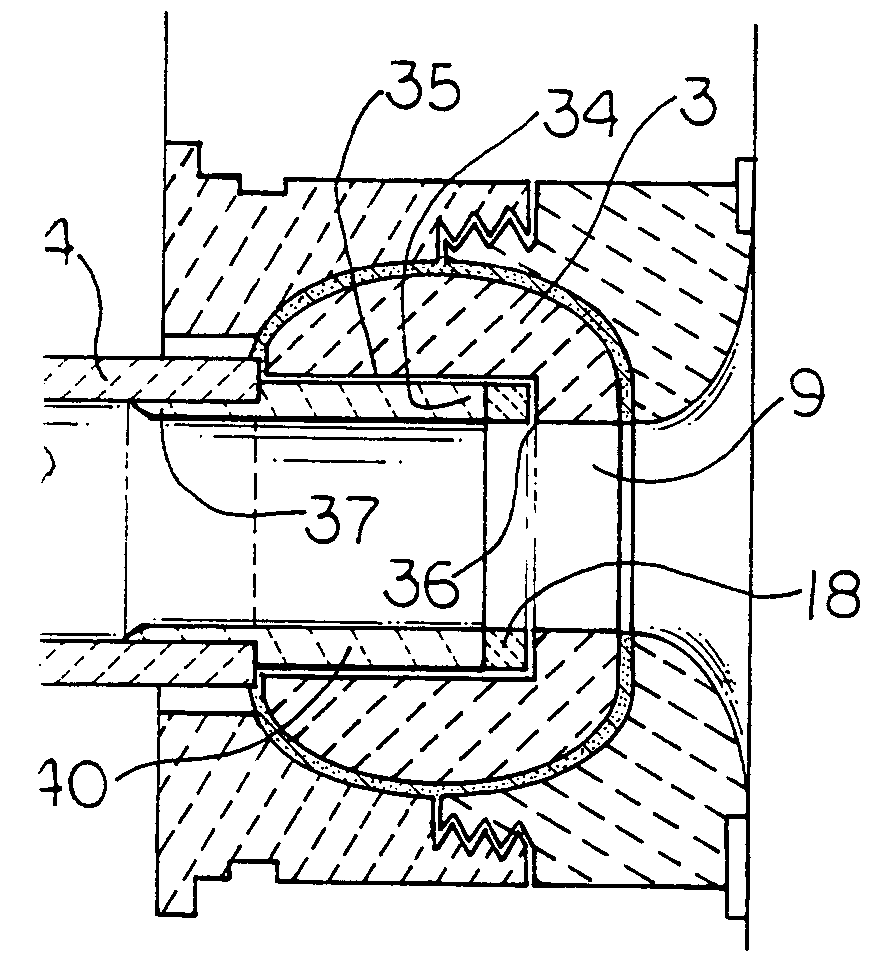

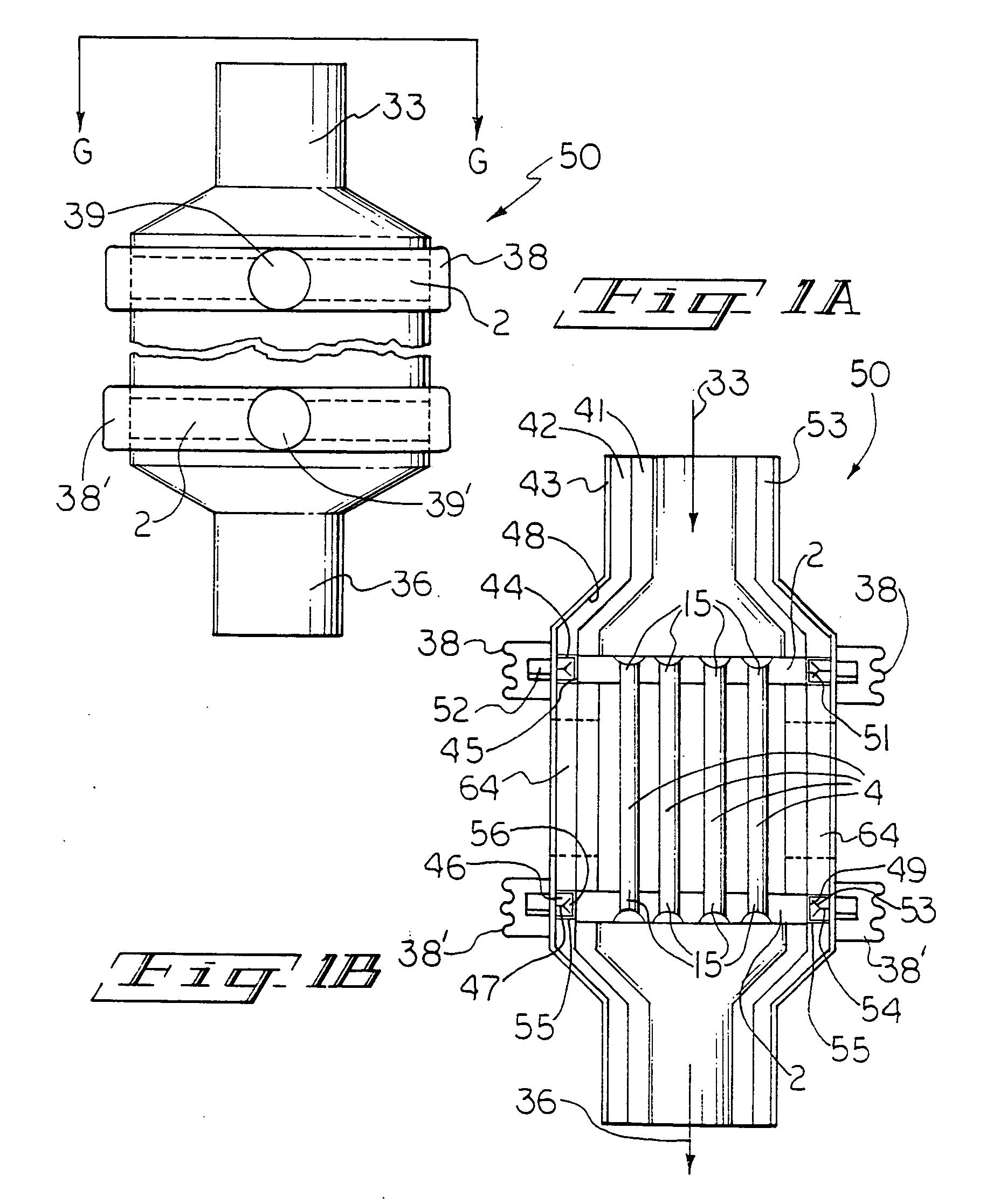

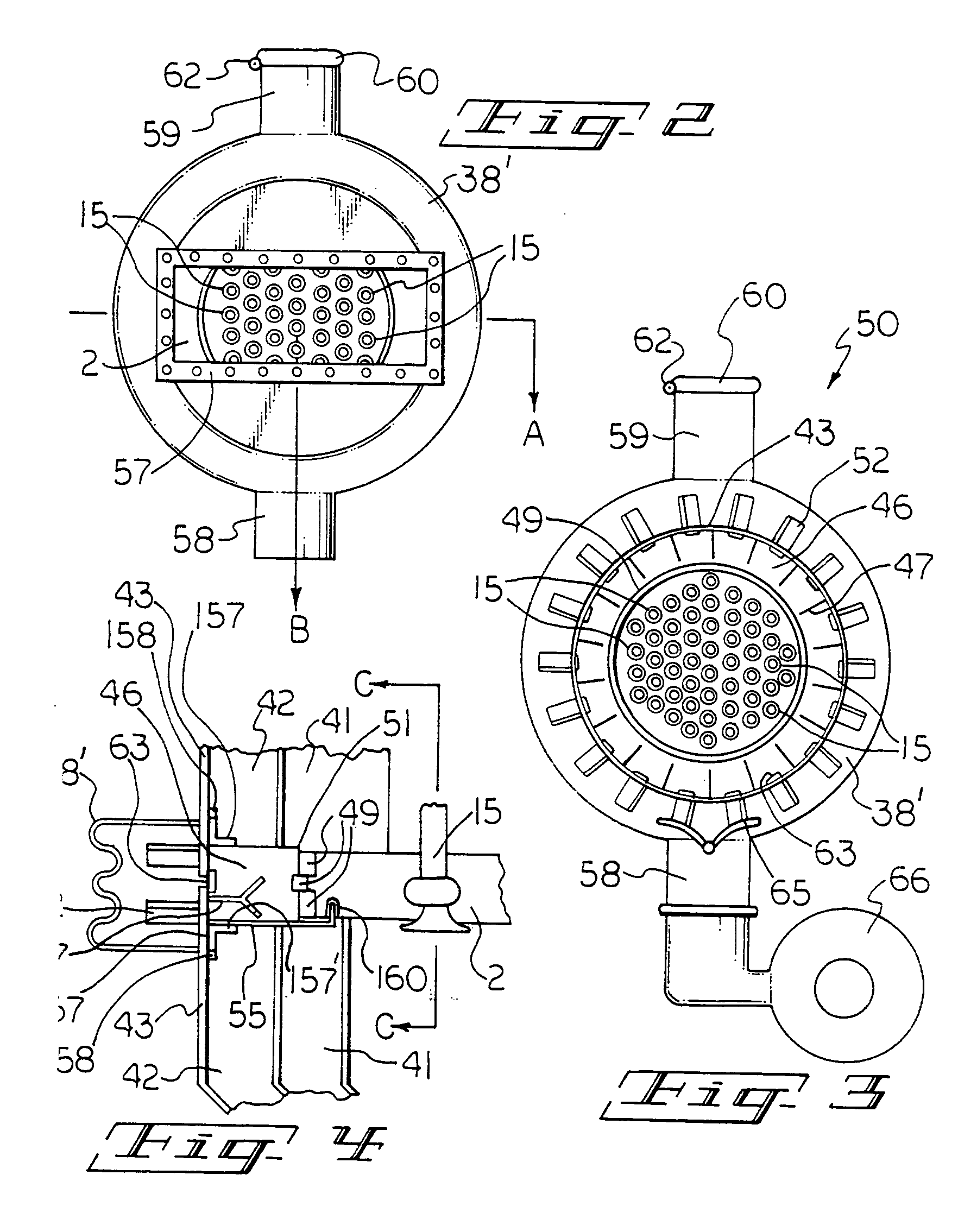

Heat exchangers with novel ball joints and assemblies and processes using such heat exchangers

InactiveUS20050051299A1Efficient heat exchangeEnhance benefitExhaust apparatusInorganic pigment treatmentProcess engineeringCarbon black

Owner:HEAT TRANSFER INT

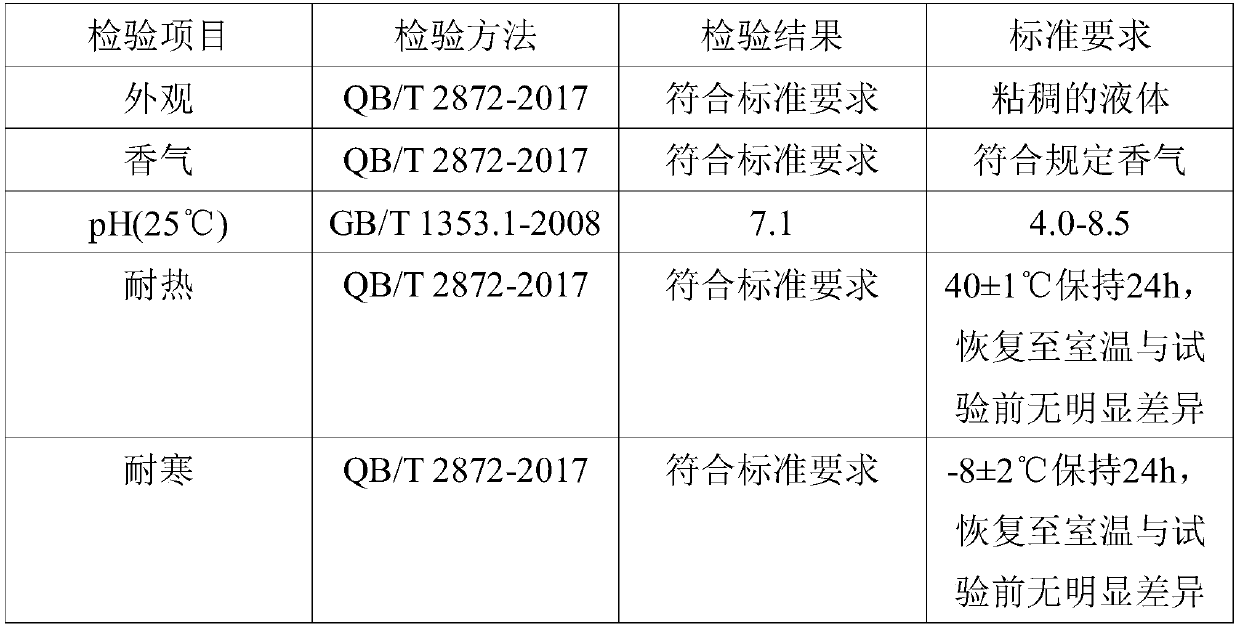

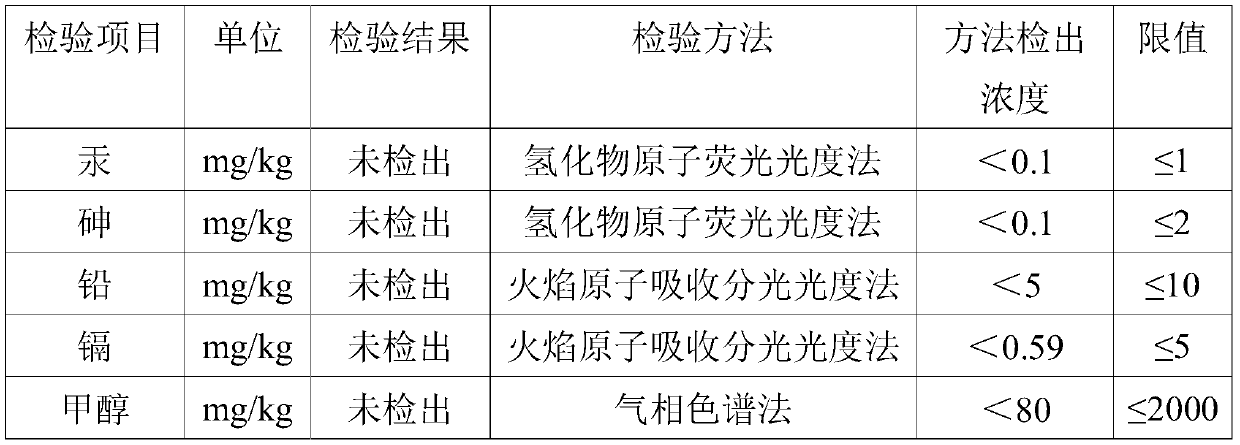

Oligopeptide repairing essence liquid and use method thereof

ActiveCN110339083AAvoid excessive additionAvoid affecting the effect of useCosmetic preparationsToilet preparationsSolventOligosaccharide

The invention discloses an oligopeptide repairing essence liquid and a use method thereof, and relates to the technical field of skin care products. The oligopeptide repairing essence liquid is composed of repairing lyophilized powder and a repairing solvent liquid, the repairing lyophilized powder contains mannitol, glutathione, oligosaccharide-1 and oligopeptide-2, and the repairing solvent liquid contains water, glycerin, propylene glycol, a dendrobium nobile stem extract, a radix sophorae extract, an aloe barbadensis leaf extract, an echinacea purpurea extract, a Ningxia fructus lycii extract, p-hydroxyacetophenone and 1,2-hexanediol. The prepared essence liquid is suitable for deep repairing of various skin injuries to improve the skin quality; the oligopeptide repairing essence liquid is particularly suitable for repairing the skin after sunburn, the skin is quickly repaired, the injury degree of the skin after sunburn is reduced, and the time for repairing the skin after sunburnis shortened.

Owner:江西中科梅氏医药有限责任公司

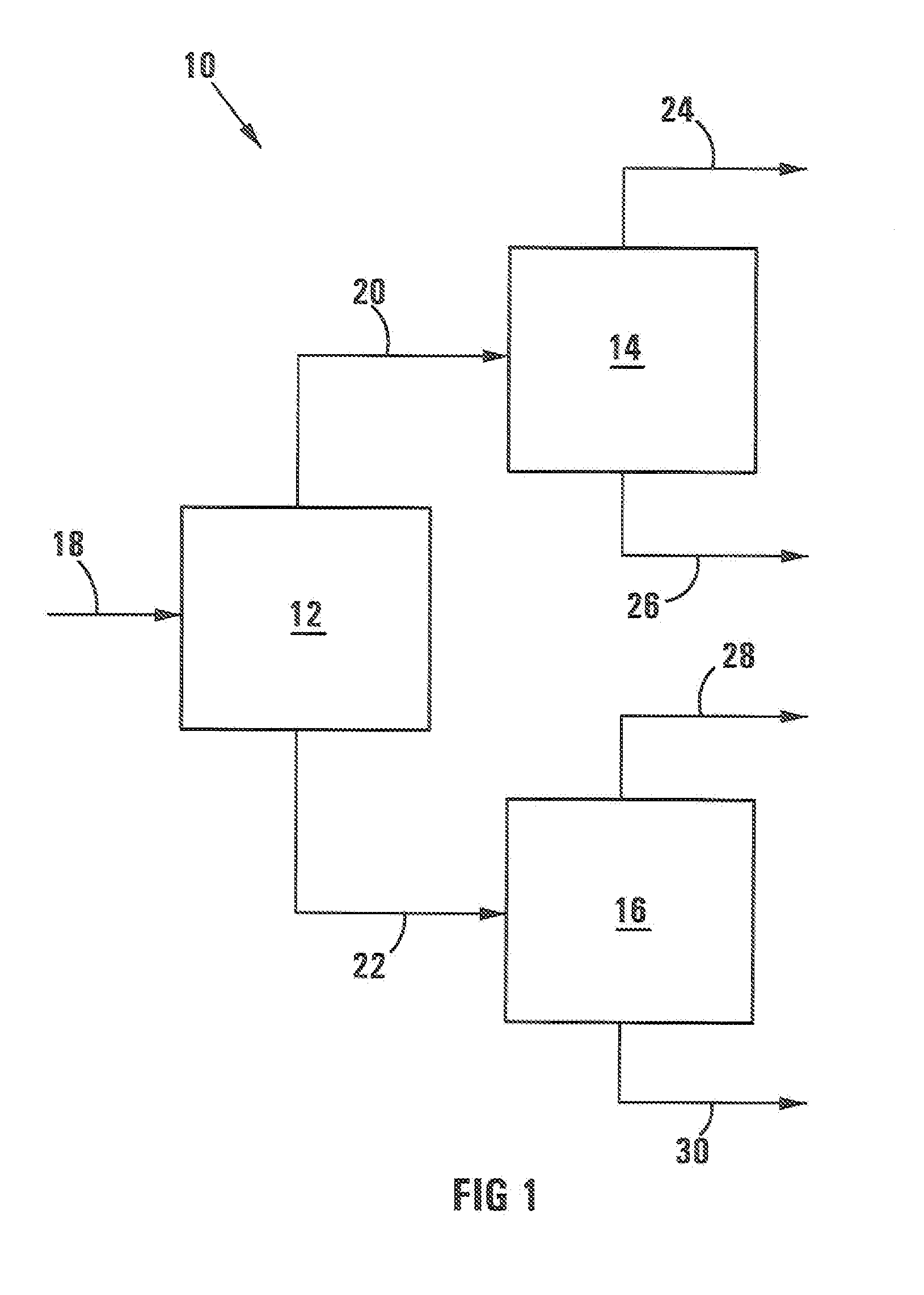

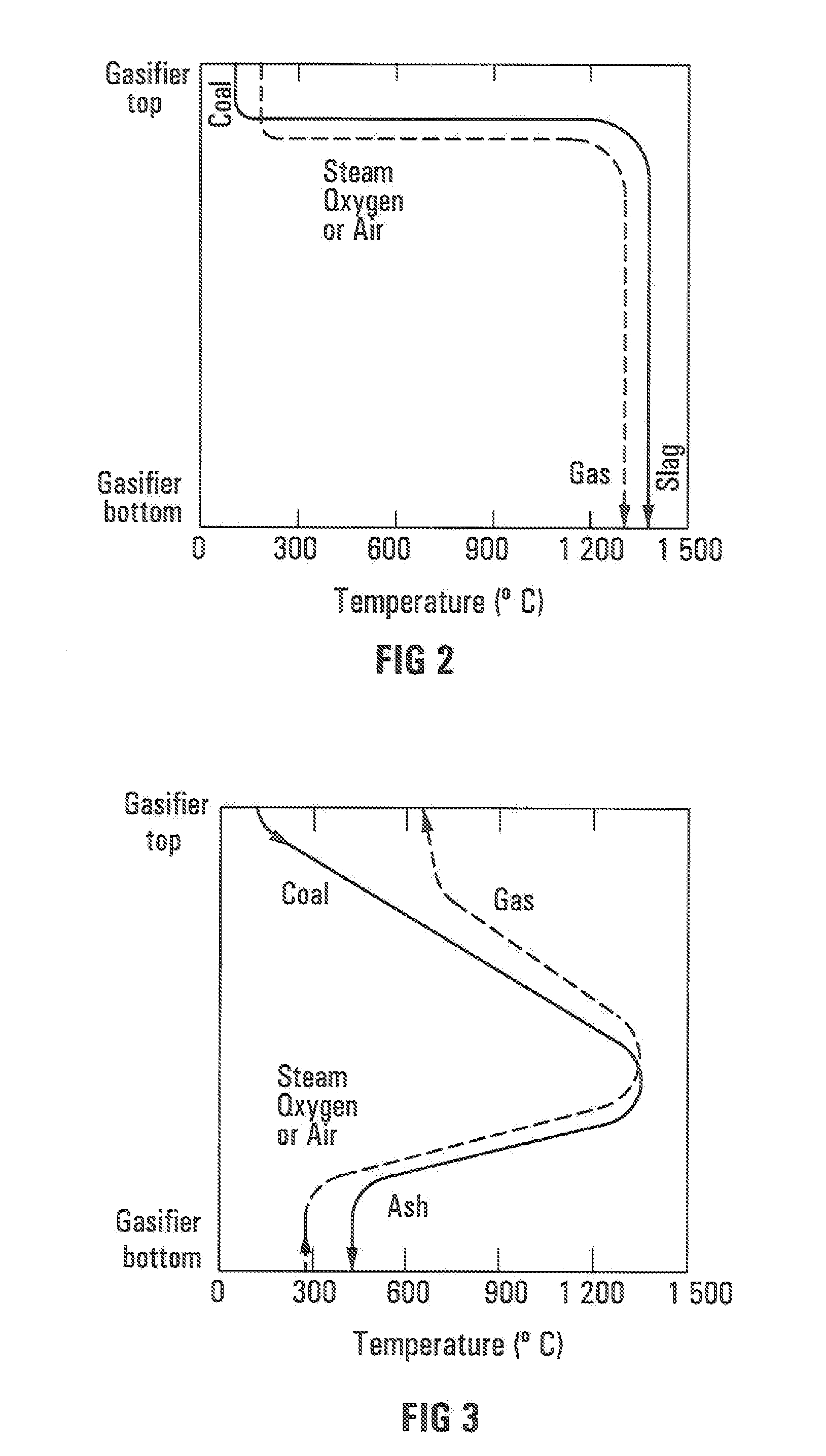

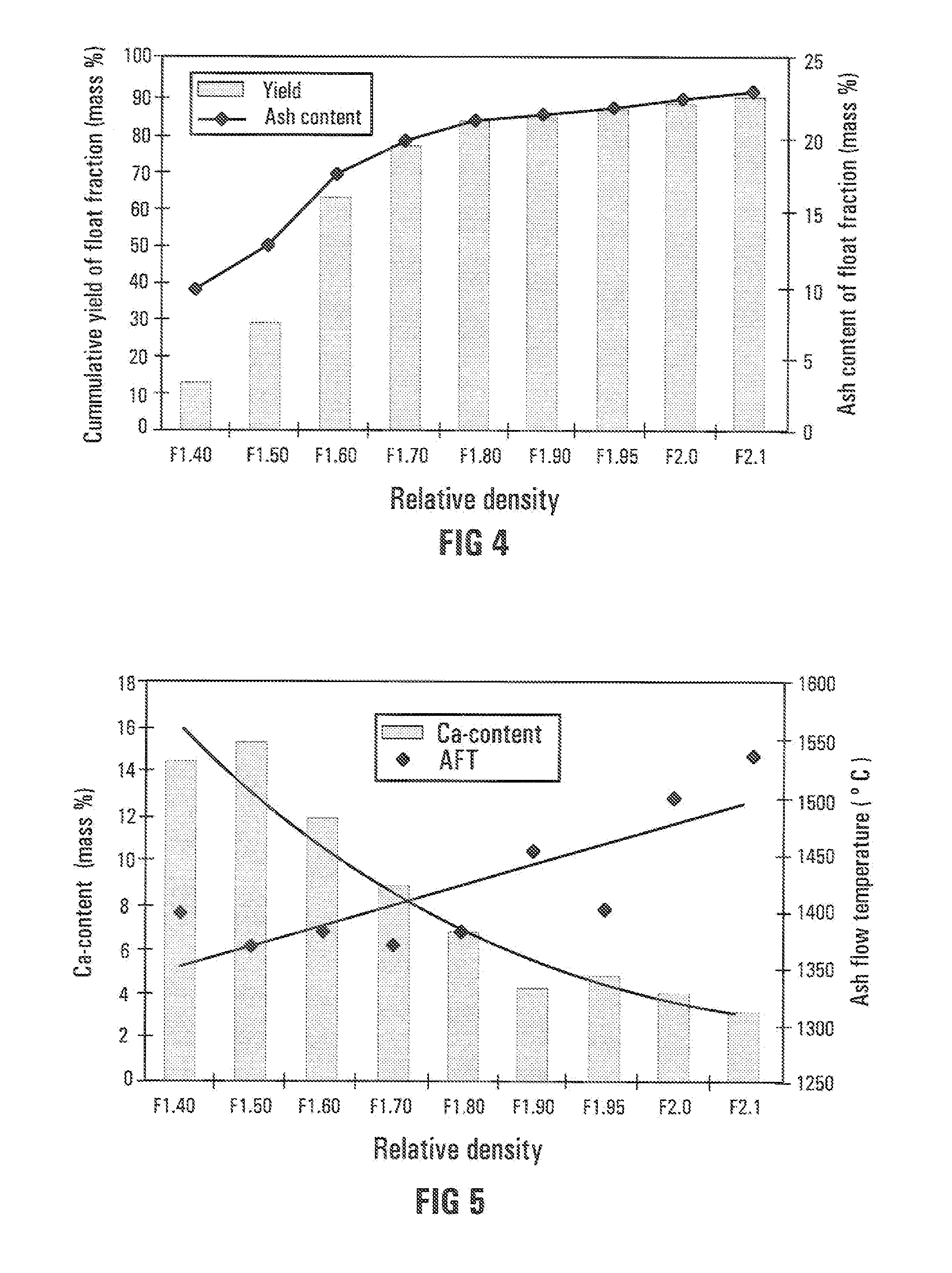

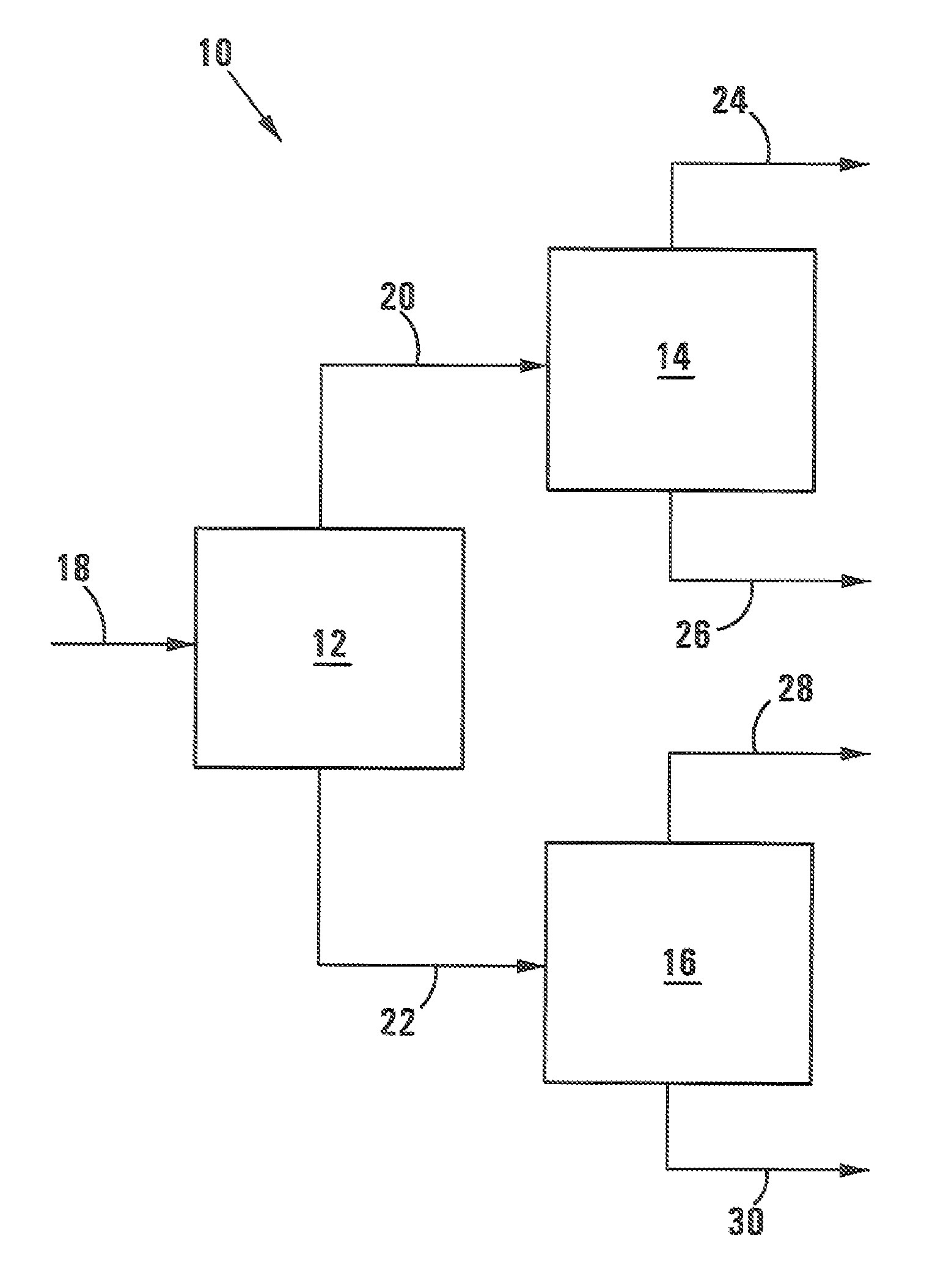

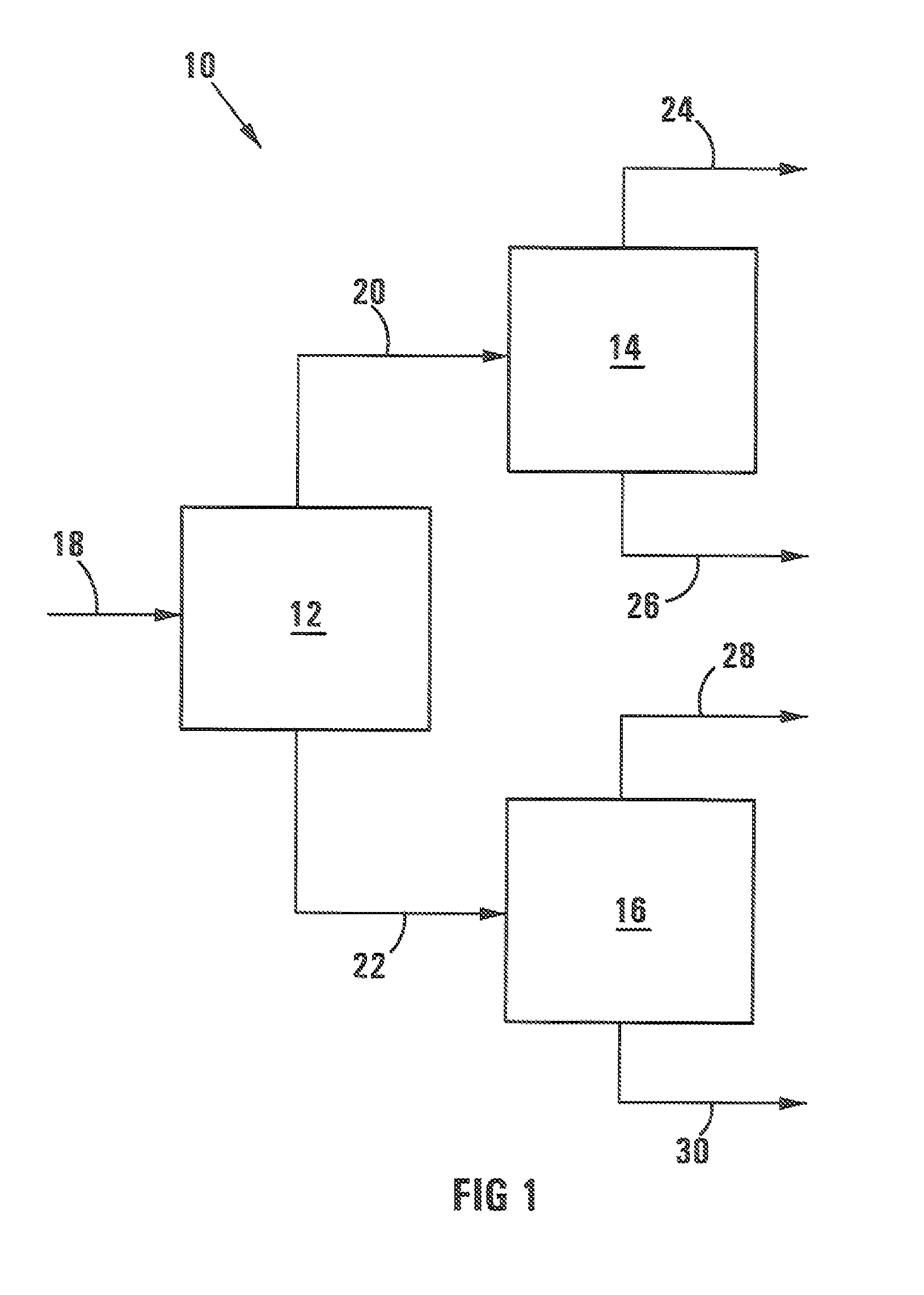

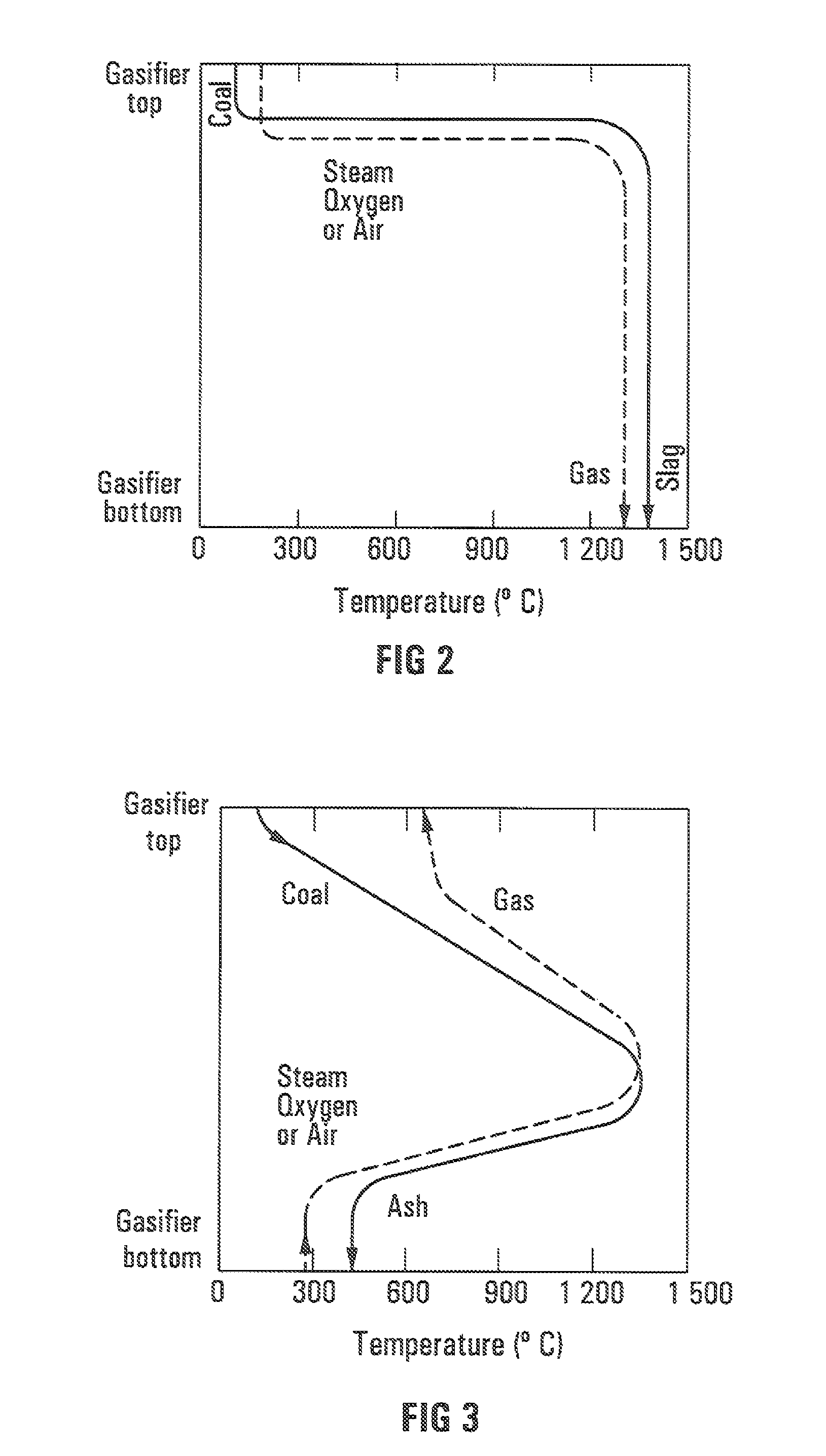

Gasification of coal

InactiveUS20110120013A1Low viscosityAvoid excessive additionSolid fuelsGasification processes detailsProcess engineeringMaceral

A coal processing operation (10) includes in a dense media separation stage (12), subjecting a coal feedstock (18) which includes minerals to dense media separation producing a first coal stream (20) and a second coal stream (22). Coal in the first coal stream (20) is lower in ash and has a lower ash fusion temperature than coal in the second coal stream (22). Coal from the first coal stream (20) is processed in a high temperature coal processing operation (44), and coal from the second coal stream (22) is processed in a medium temperature coal processing operation (16).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

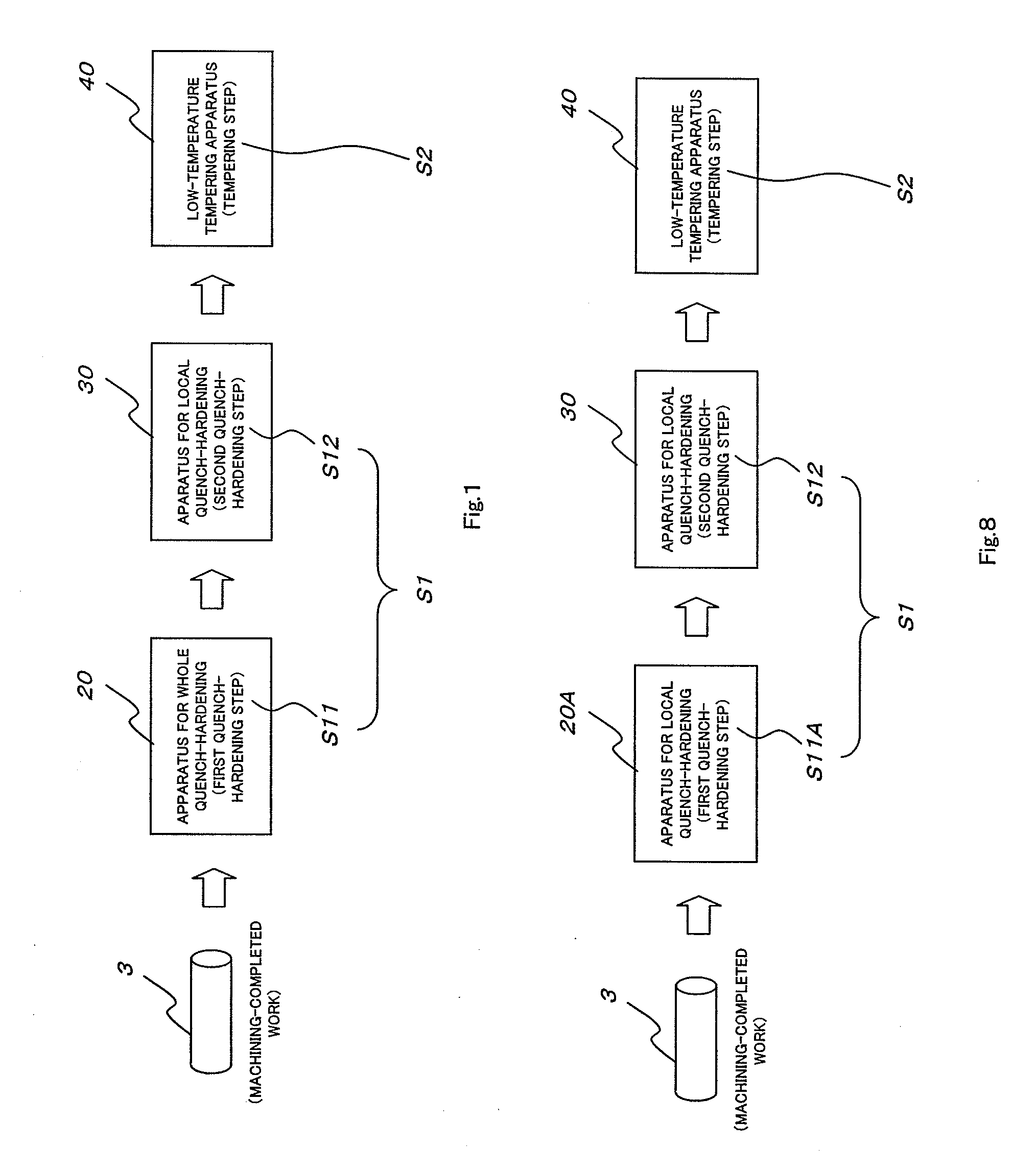

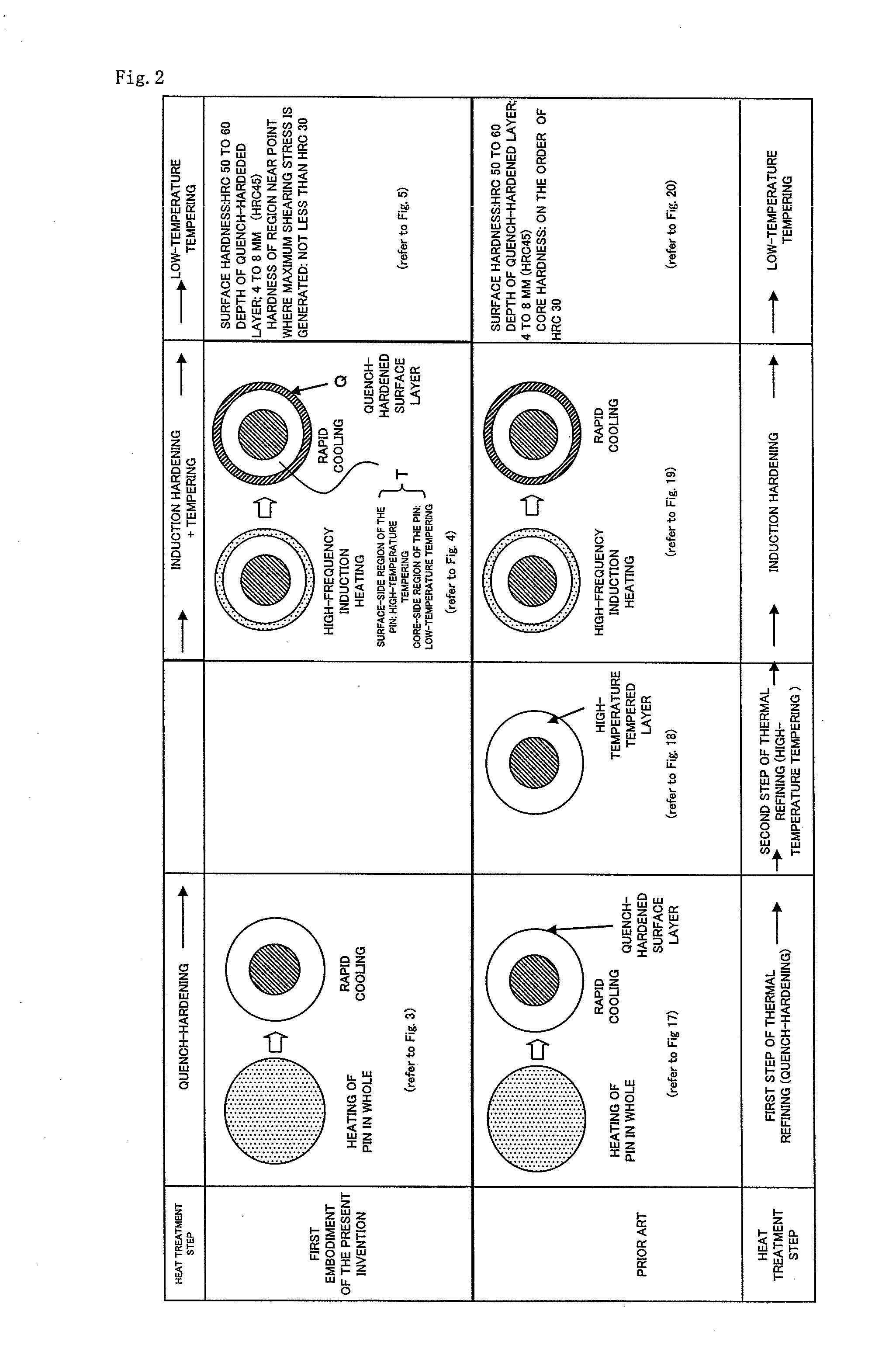

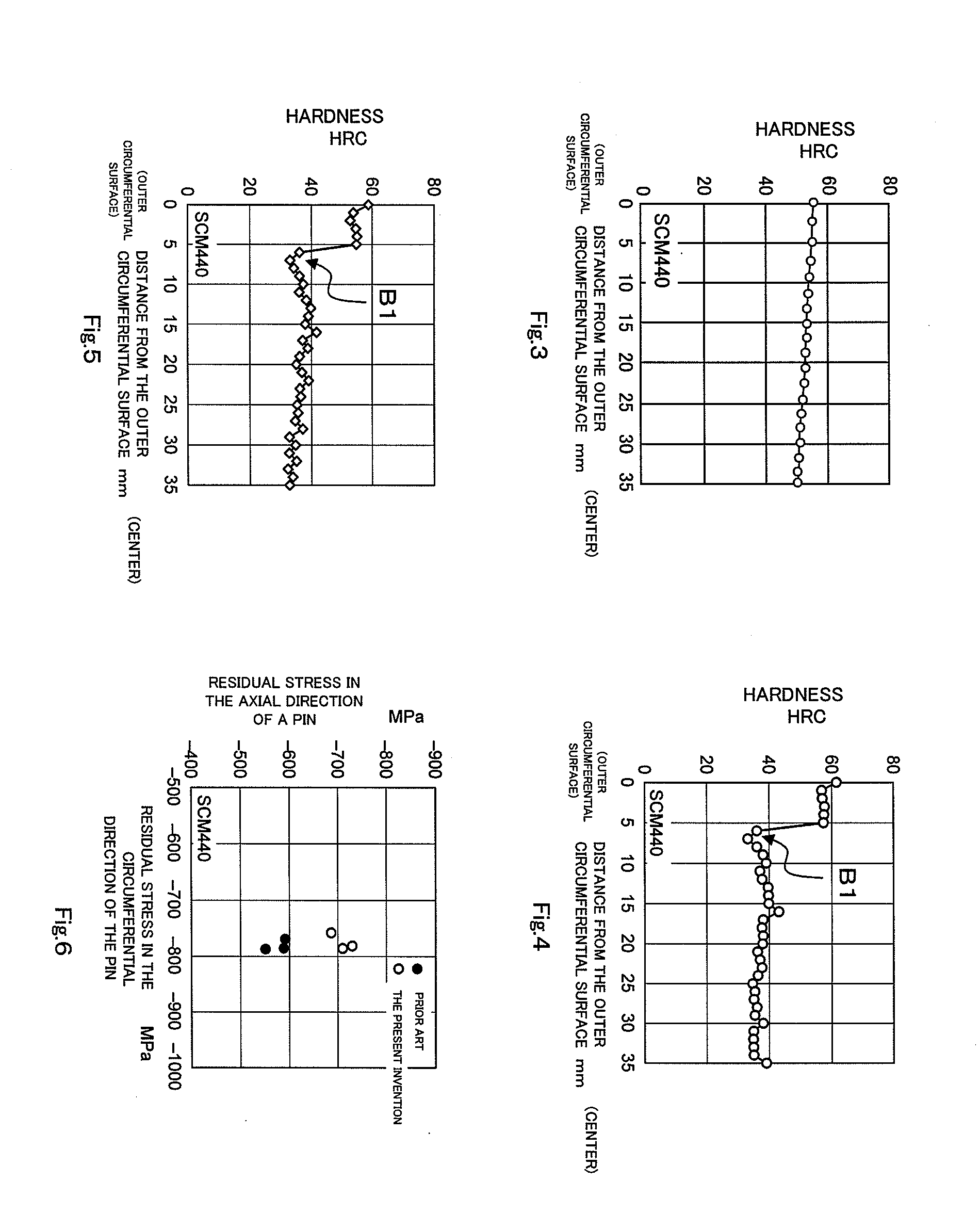

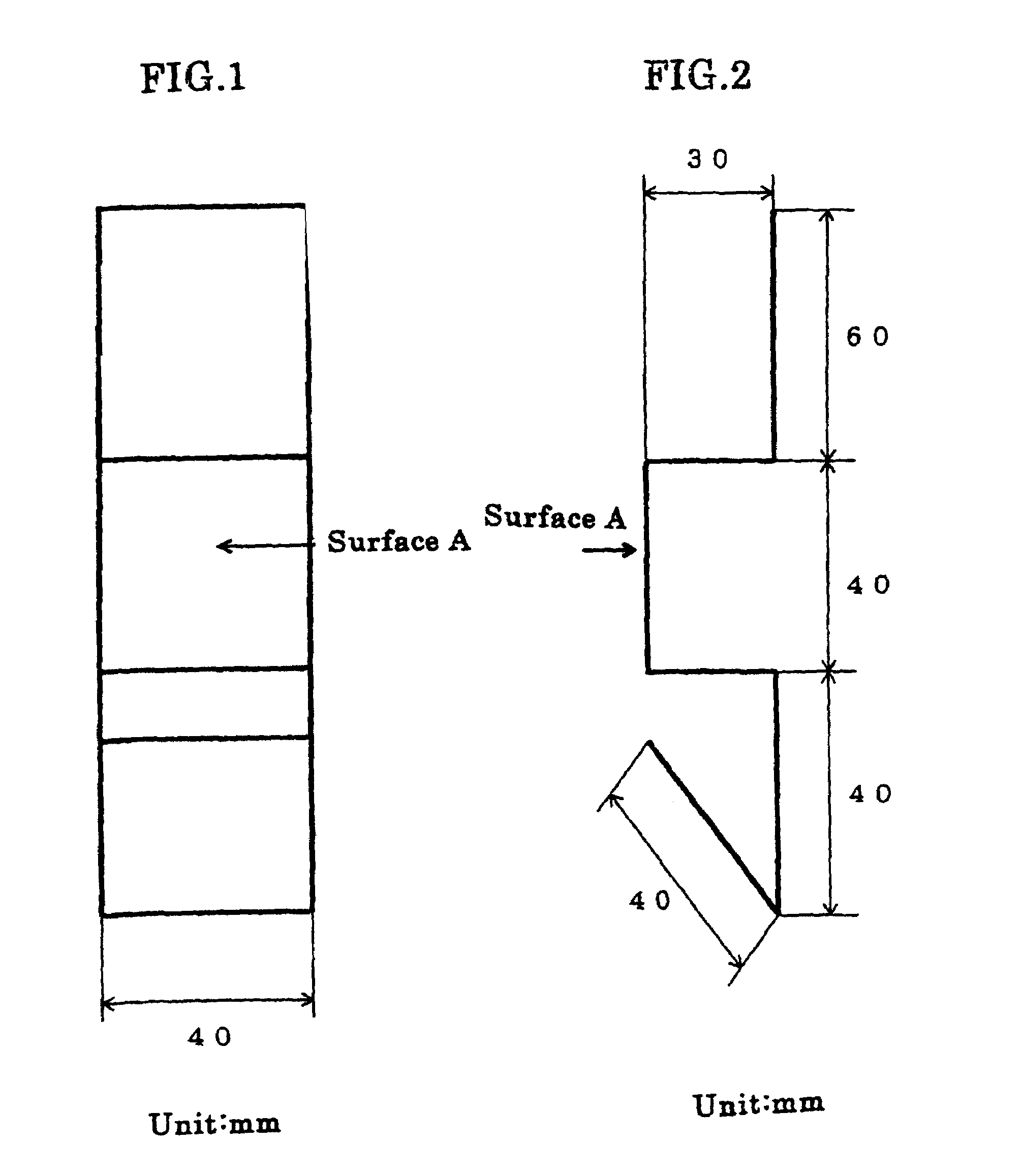

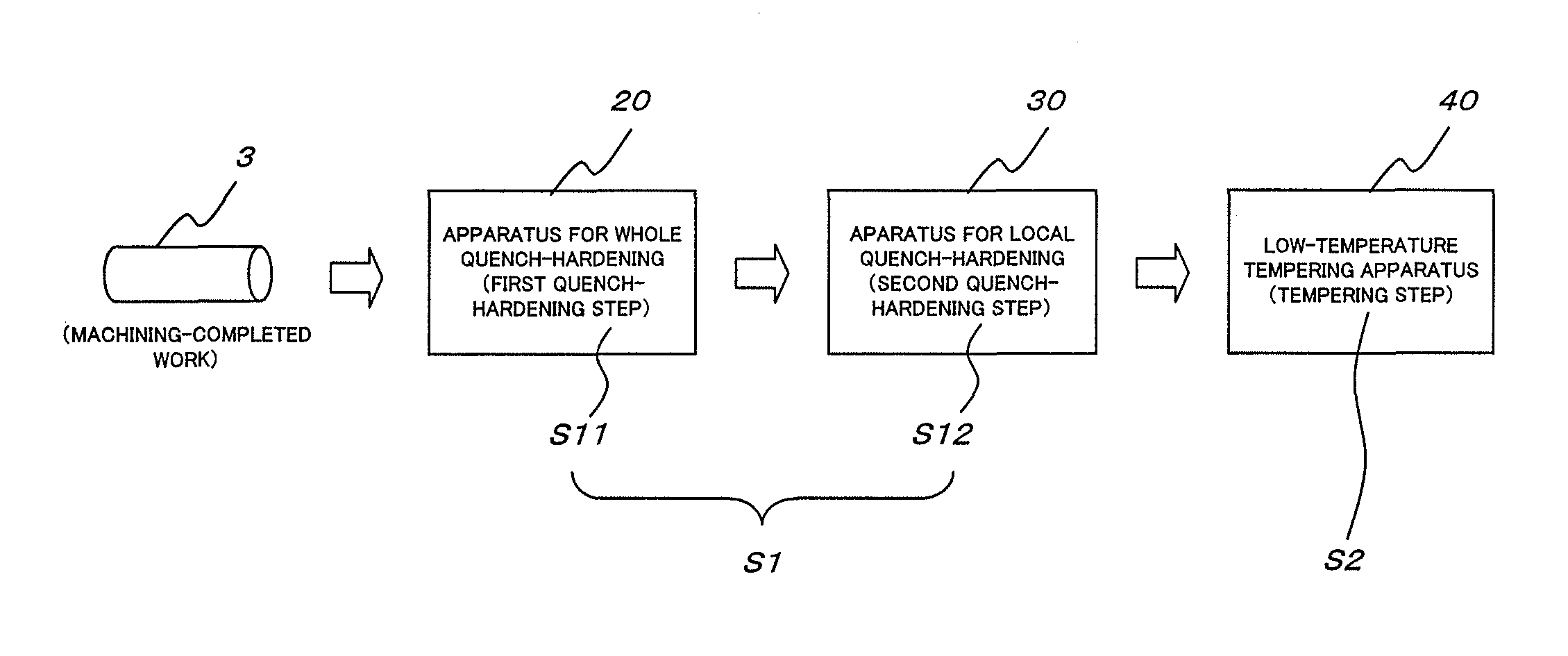

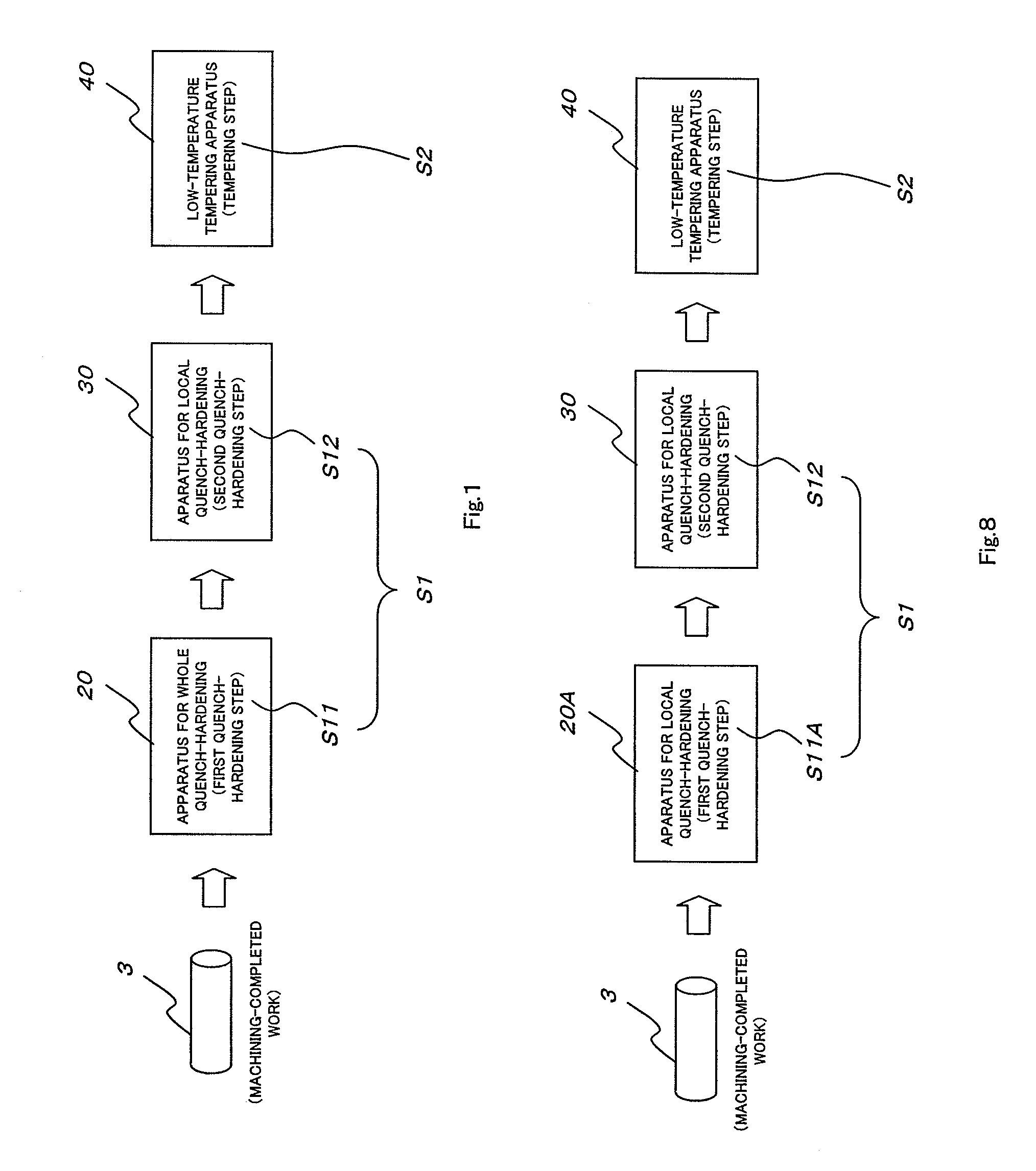

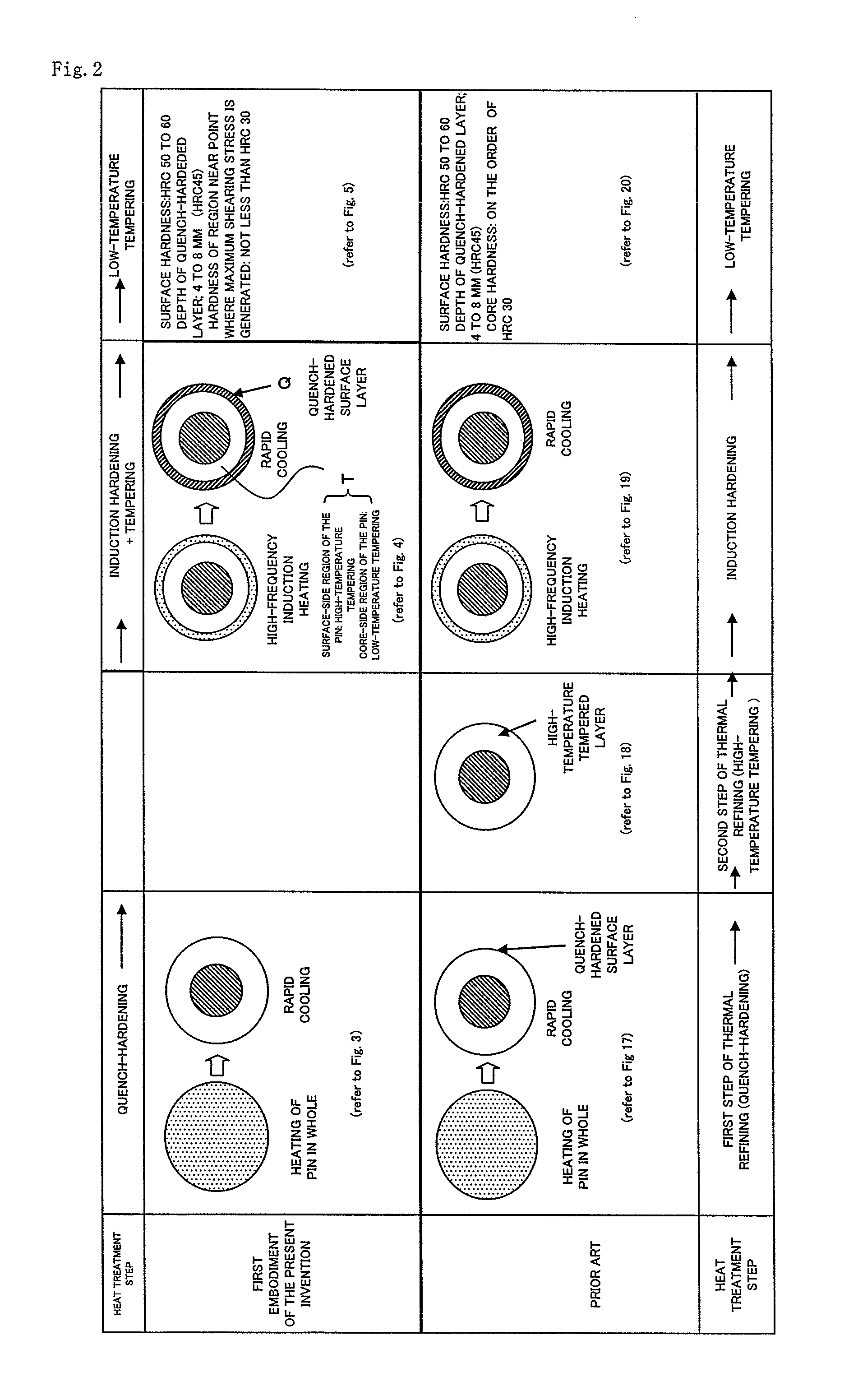

Method for heat treatment of columnar work

InactiveUS20100252150A1Improve productivityManufacturing cost be reduceIncreasing energy efficiencyFurnace typesProduction rateMaterials science

Owner:TOPY INDUSTRIES

Coal processing operation comprising a dense media separation stage to separate a coal feedstock into lower and higher ash coal streams

InactiveUS8906122B2Low viscosityAvoid excessive additionHydrogenSolid fuelsProcess engineeringMaceral

A coal processing operation (10) includes in a dense media separation stage (12), subjecting a coal feedstock (18) which includes minerals to dense media separation producing a first coal stream (20) and a second coal stream (22). Coal in the first coal stream (20) is lower in ash and has a lower ash fusion temperature than coal in the second coal stream (22). Coal from the first coal stream (20) is processed in a high temperature coal processing operation (44), and coal from the second coal stream (22) is processed in a medium temperature coal processing operation (16).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

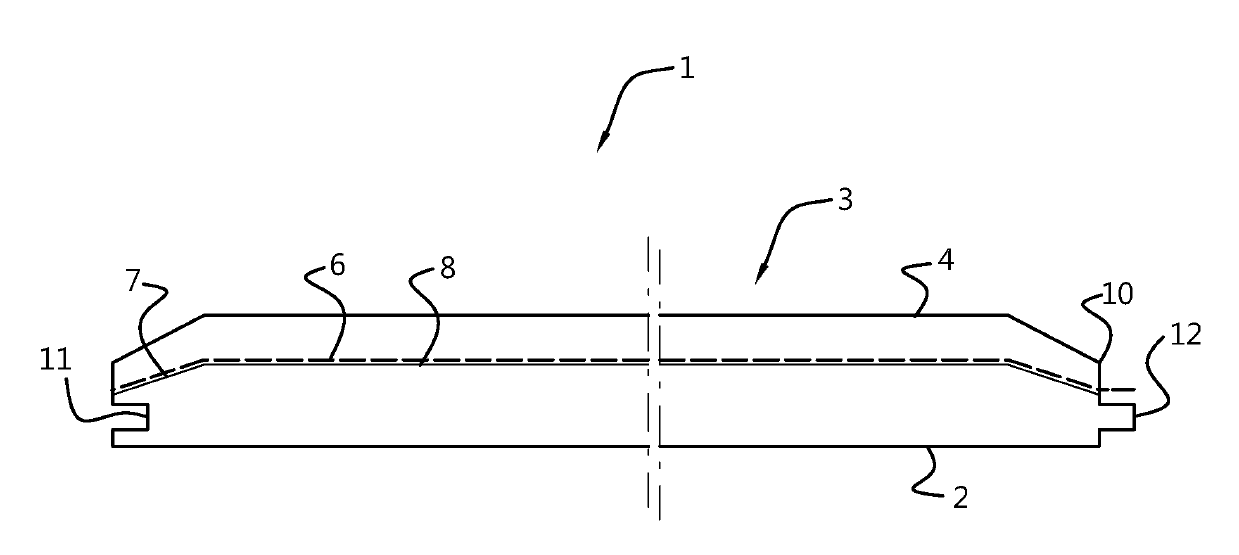

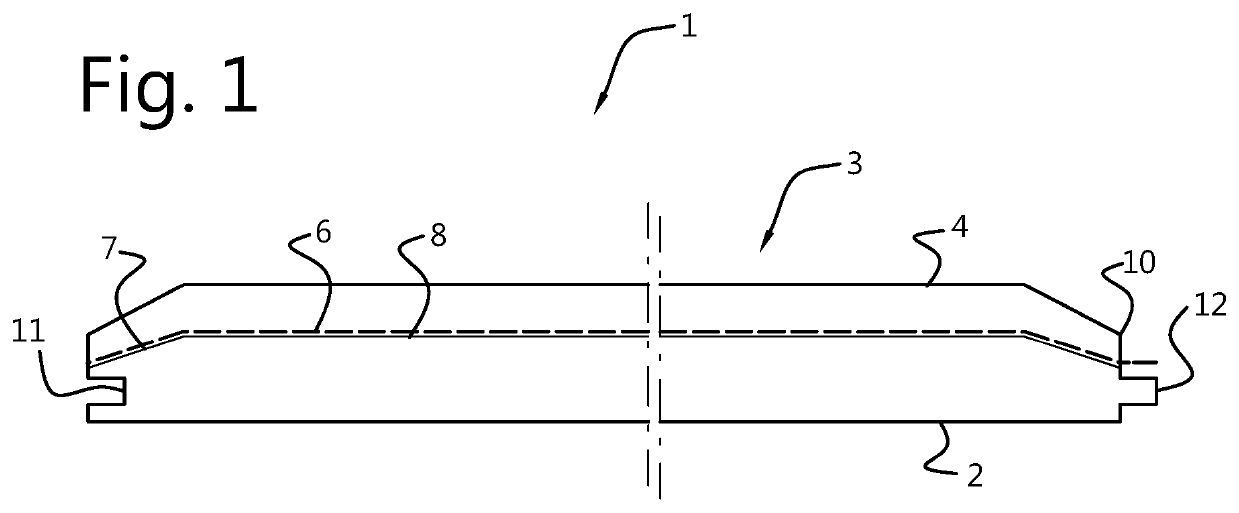

Covering and method for producing coverings

ActiveUS10513855B2Good effectCost effectiveConstruction materialCovering/liningsSurface layerEngineering

The current invention concerns coverings such as a floor covering, wall covering or ceiling covering, said covering comprising at least one substrate and at least one surface layer, said surface layer comprising a print pattern and a wear layer, whereby said print pattern is directly applied to said substrate, and further concerns a method to produce such coverings.

Owner:BEAULIEU INTERNATIONAL GROUP

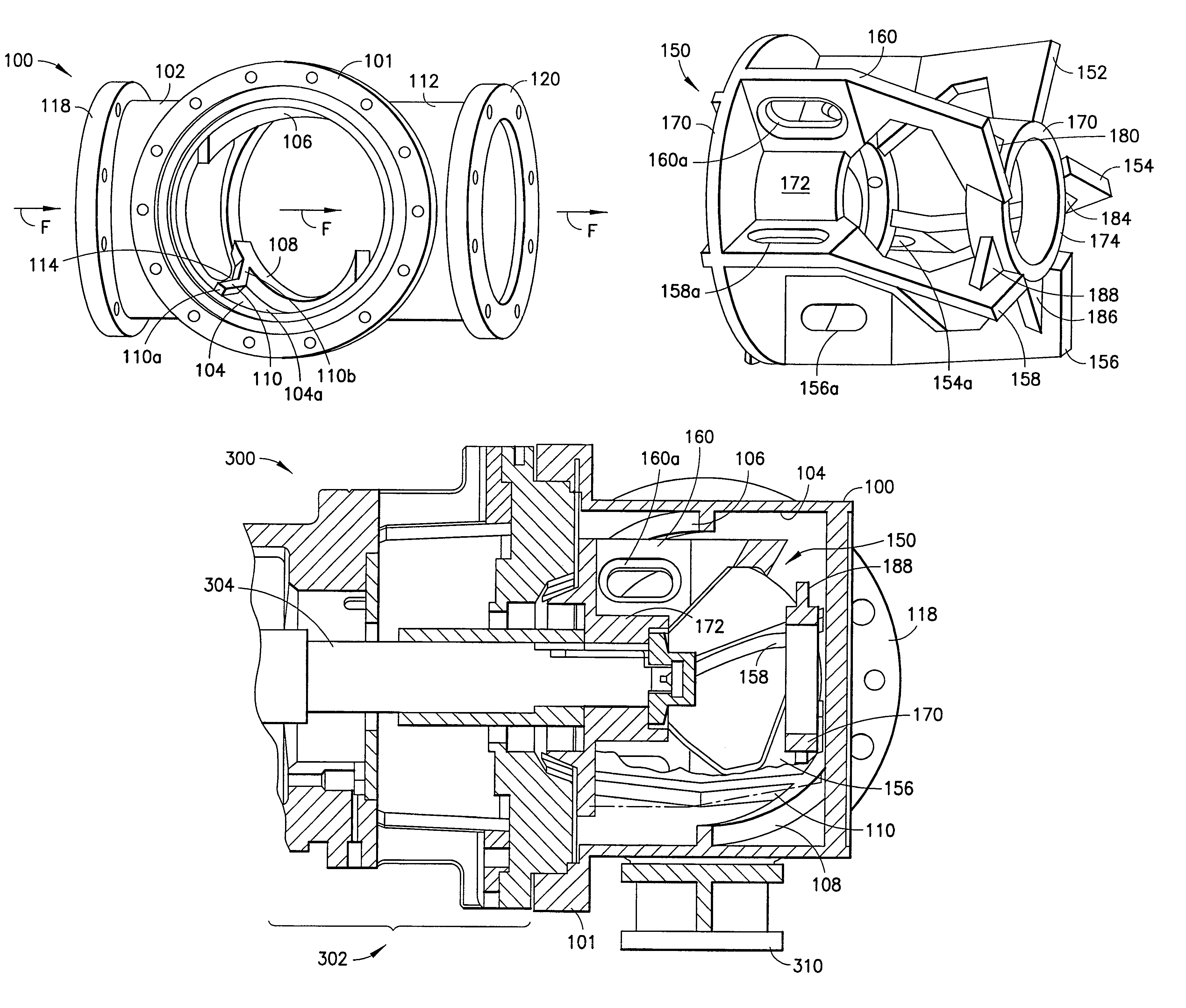

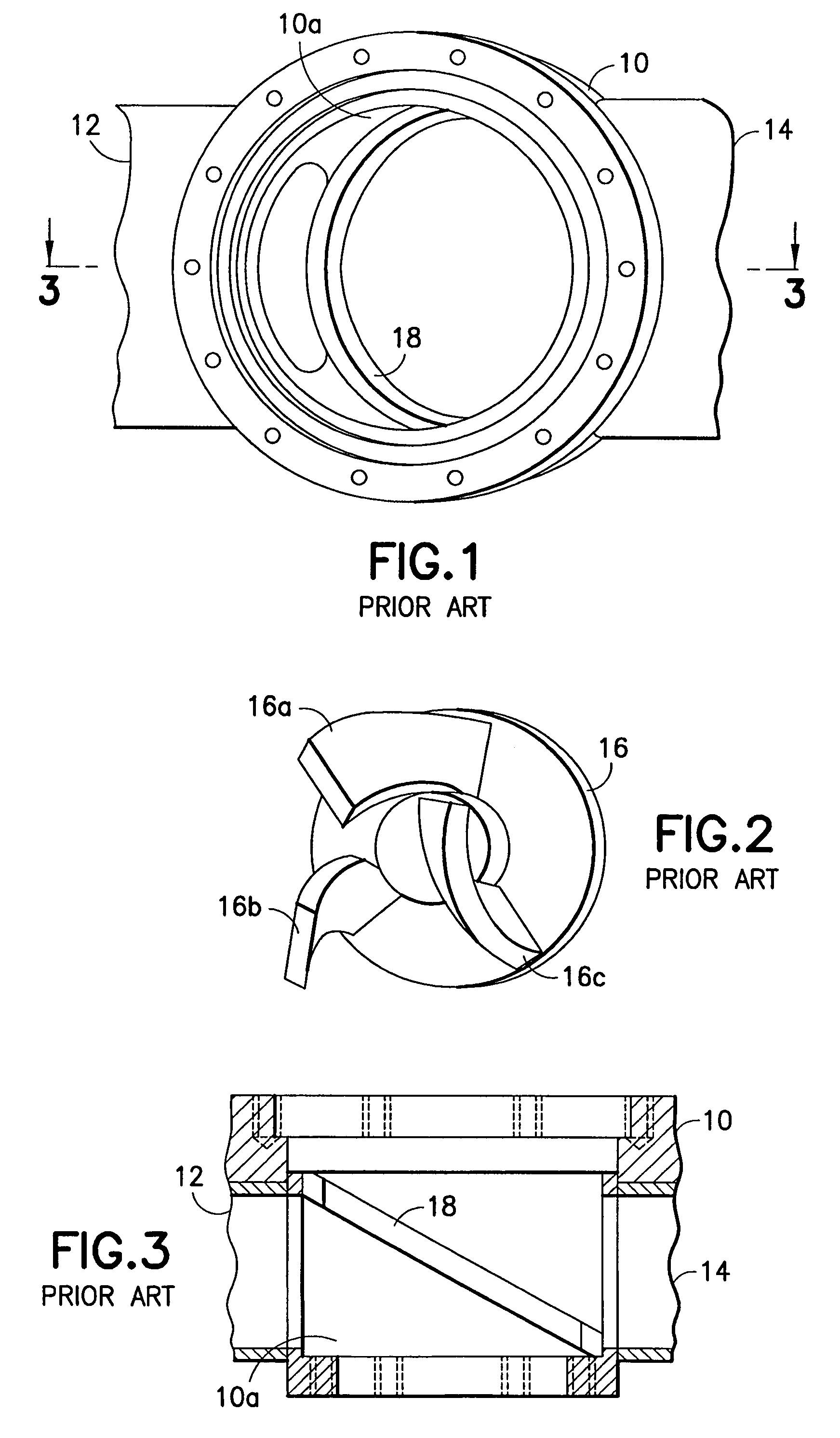

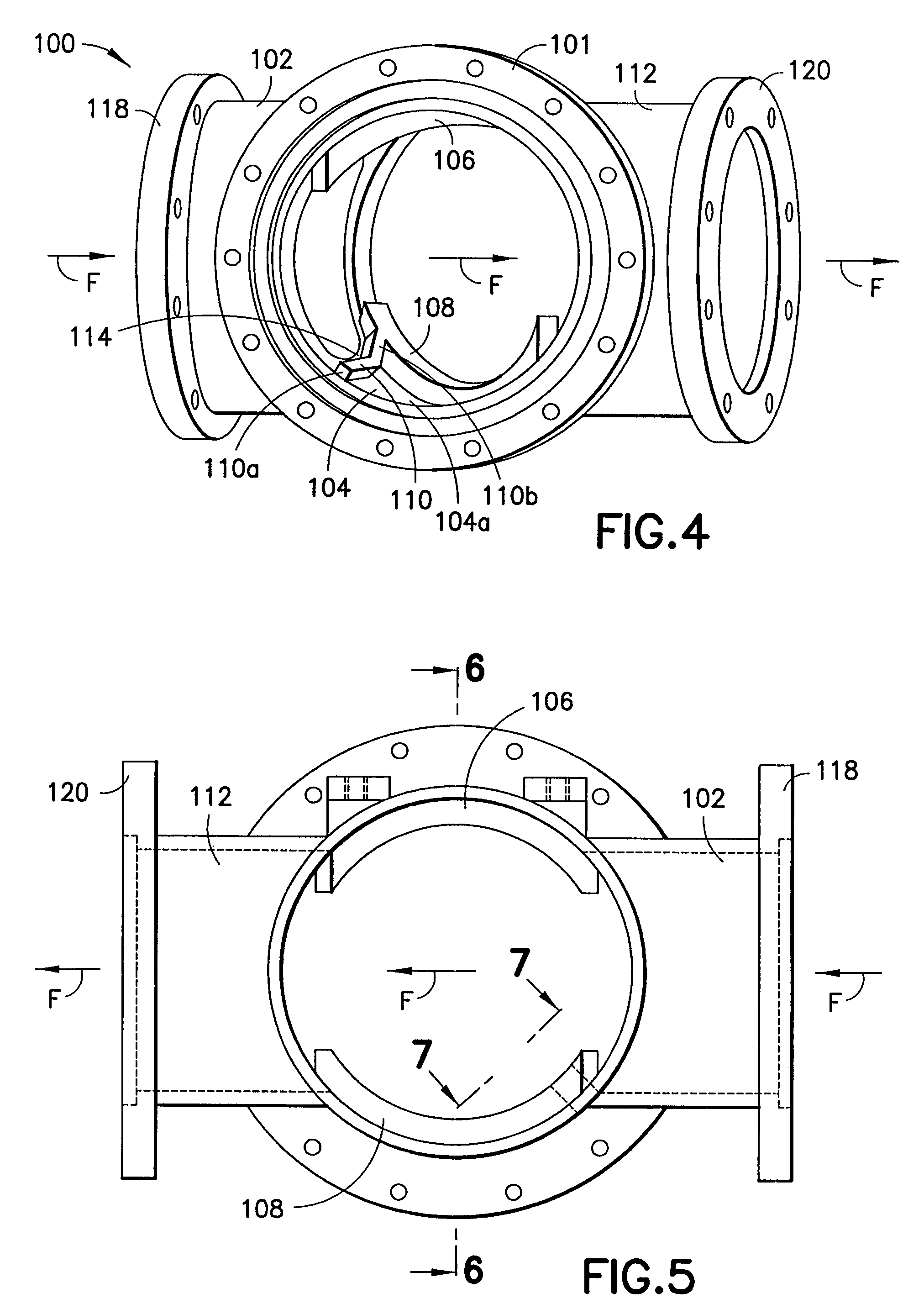

Inline high turbulence mixer having combined oblique and transverse stationary vanes

InactiveUS6880966B1Minimize pressure pulsationImprove mixing efficiencyFlow mixersRotary stirring mixersEngineeringProcess engineering

Owner:ITT MFG ENTERPRISES LLC

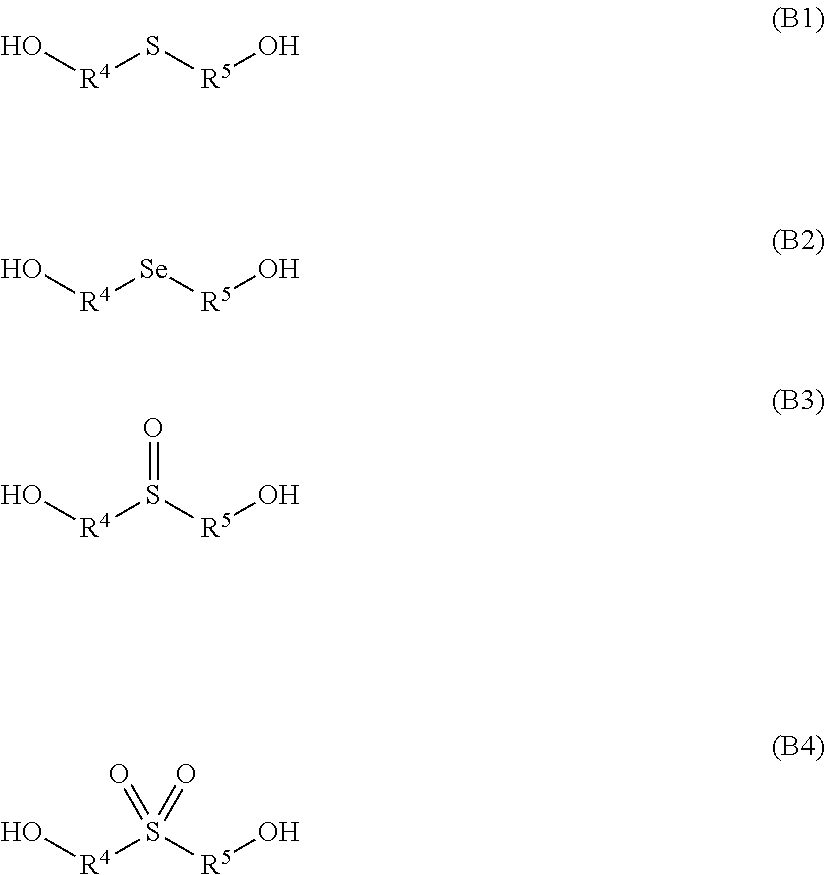

Water-emulsifiable isocyanates for coatings having an improved gloss

InactiveUS20160075912A1Good dispersionAvoid excessive additionPolyurea/polyurethane coatingsPolymer scienceCyanate ester

Owner:BASF AG

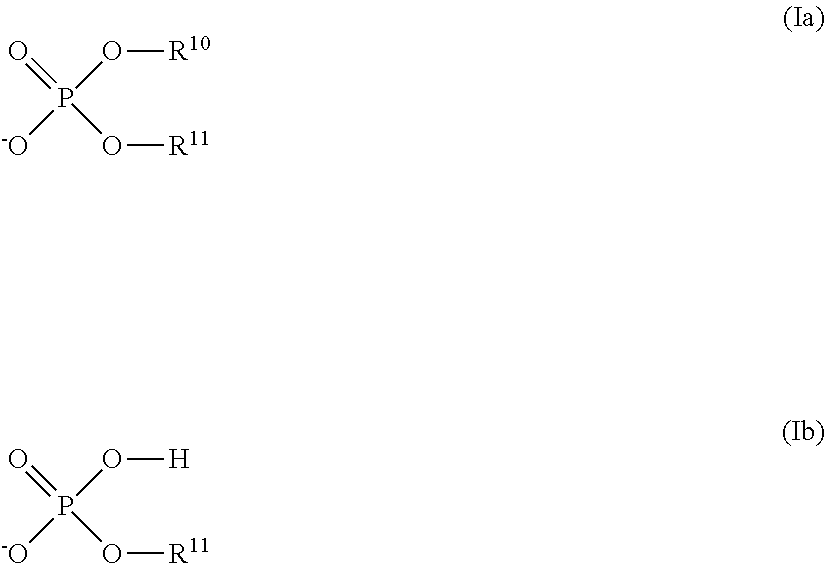

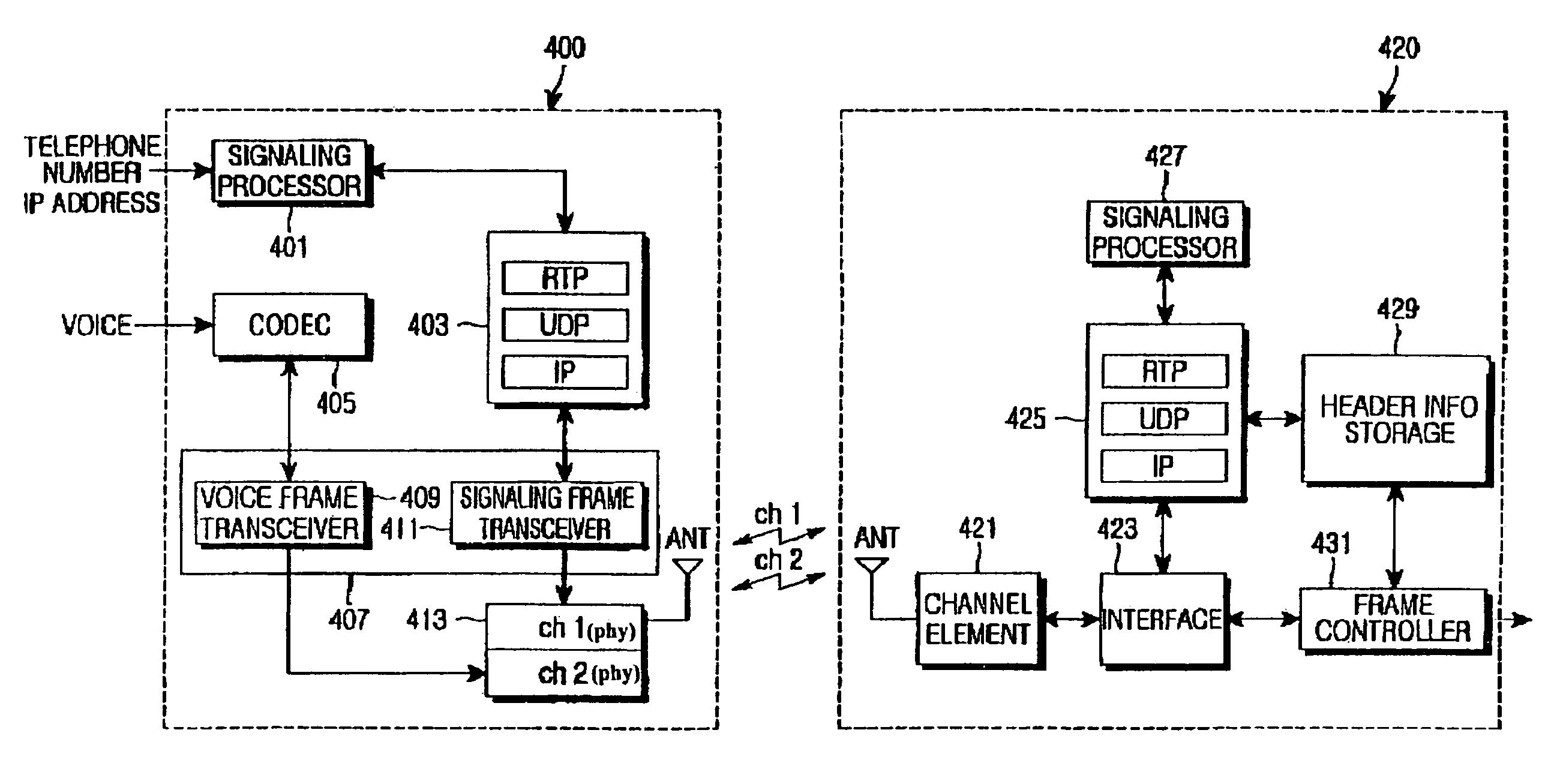

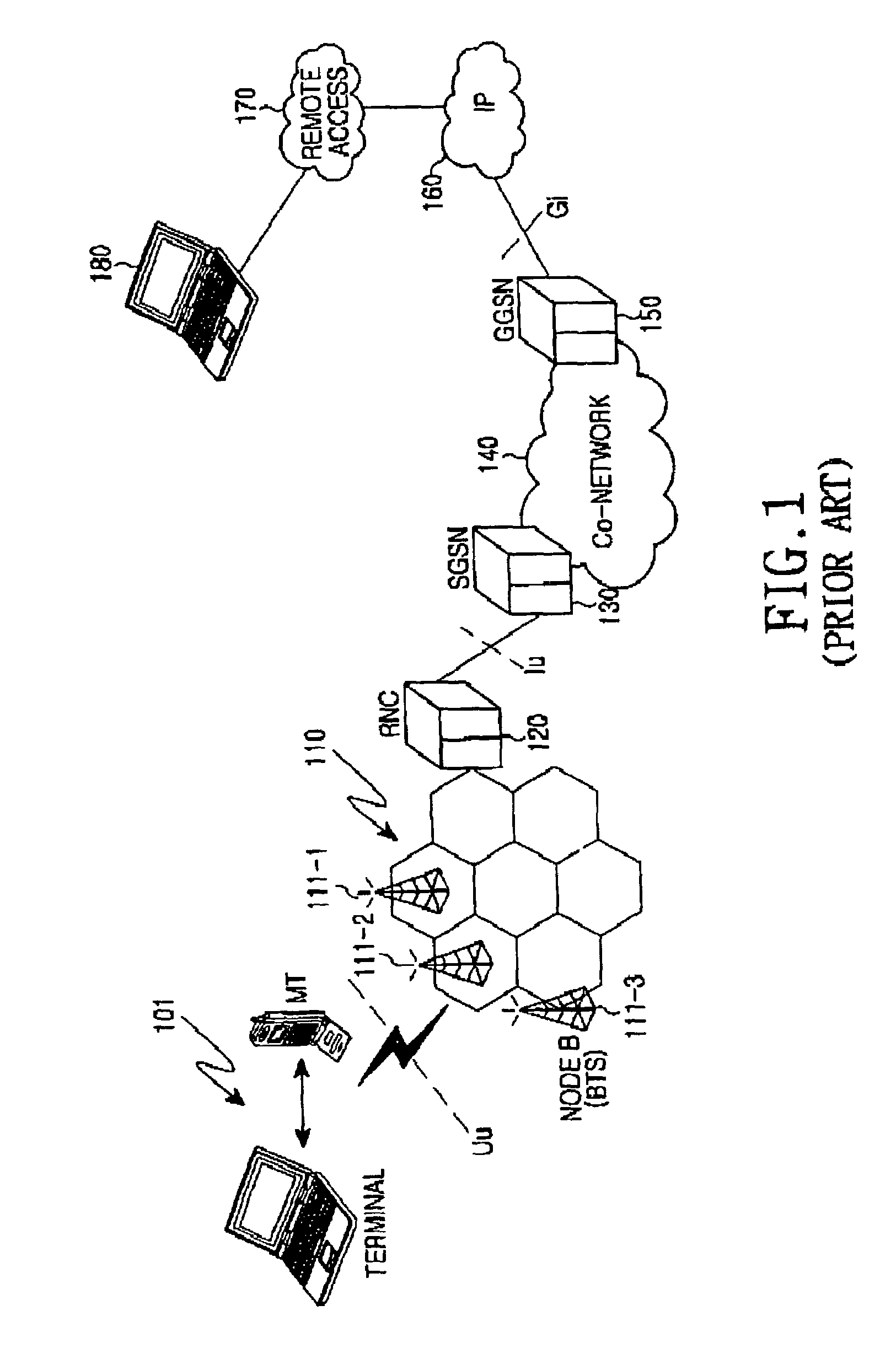

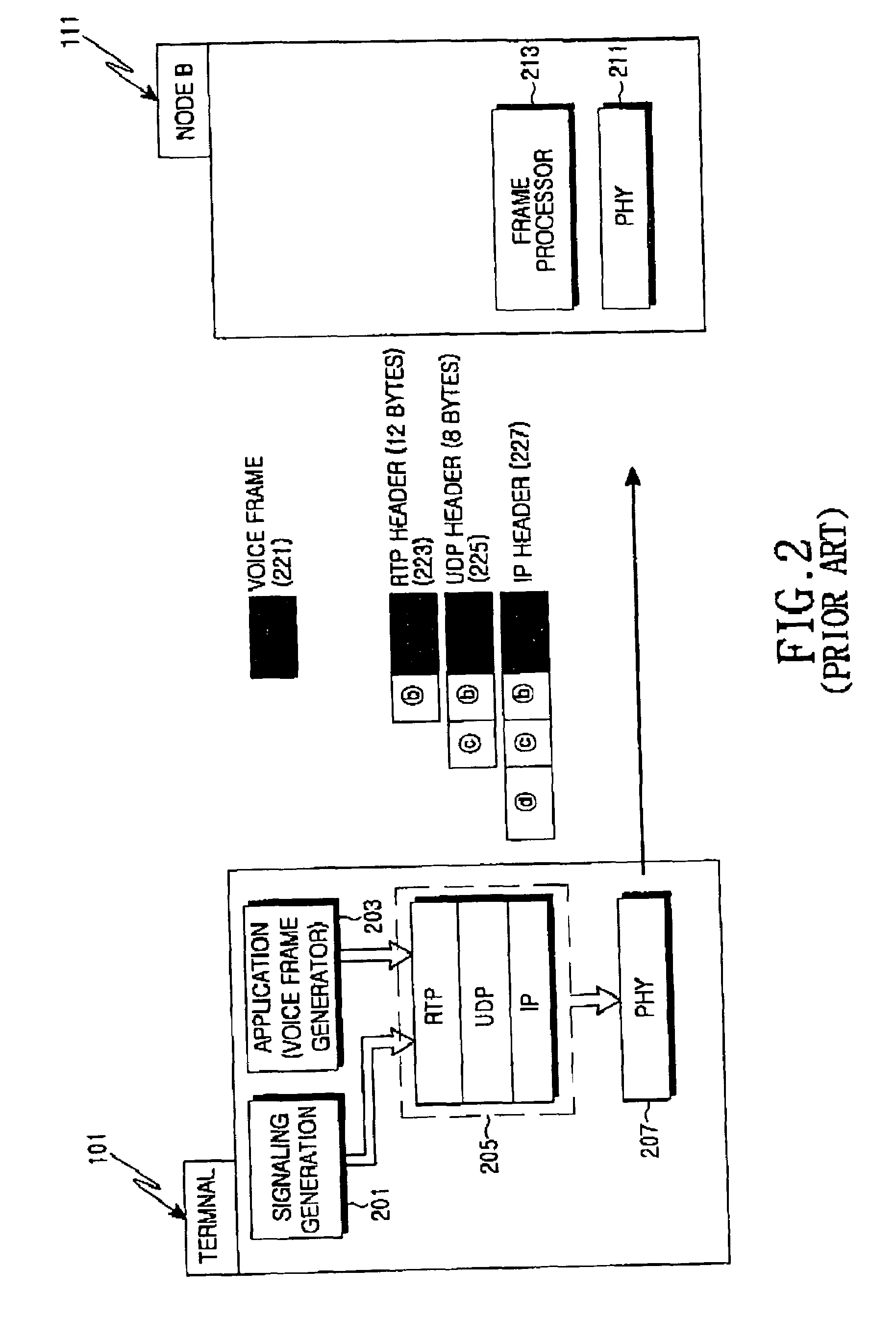

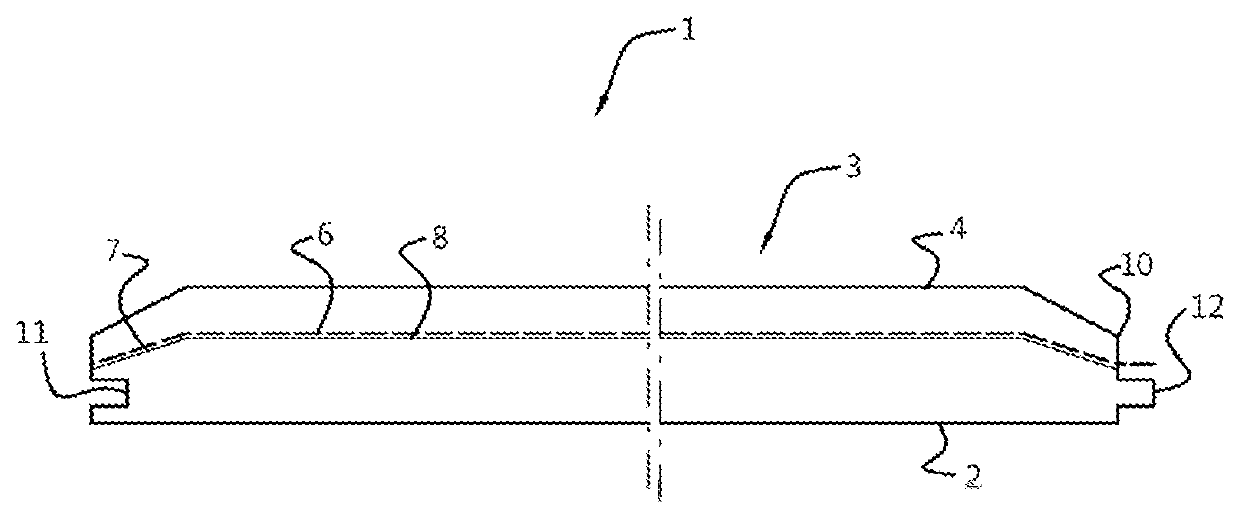

Apparatus and method for transmitting a voice frame in an ALL-IP-based mobile communication system

InactiveUS7292554B2Avoid excessive additionNetwork traffic/resource managementTime-division multiplexVoice trafficMobile communication systems

A method for transmitting voice traffic in an ALL-IP-based mobile communication system. A mobile terminal first transmits header information using a signaling frame, and then separately transmits only a voice frame. A Node B detects the header information from the signaling frame received, stores the detected header information, and upon receipt of the voice frame, adds the header information to the voice frame and transmits the header-added voice frame to a core network.

Owner:SAMSUNG ELECTRONICS CO LTD

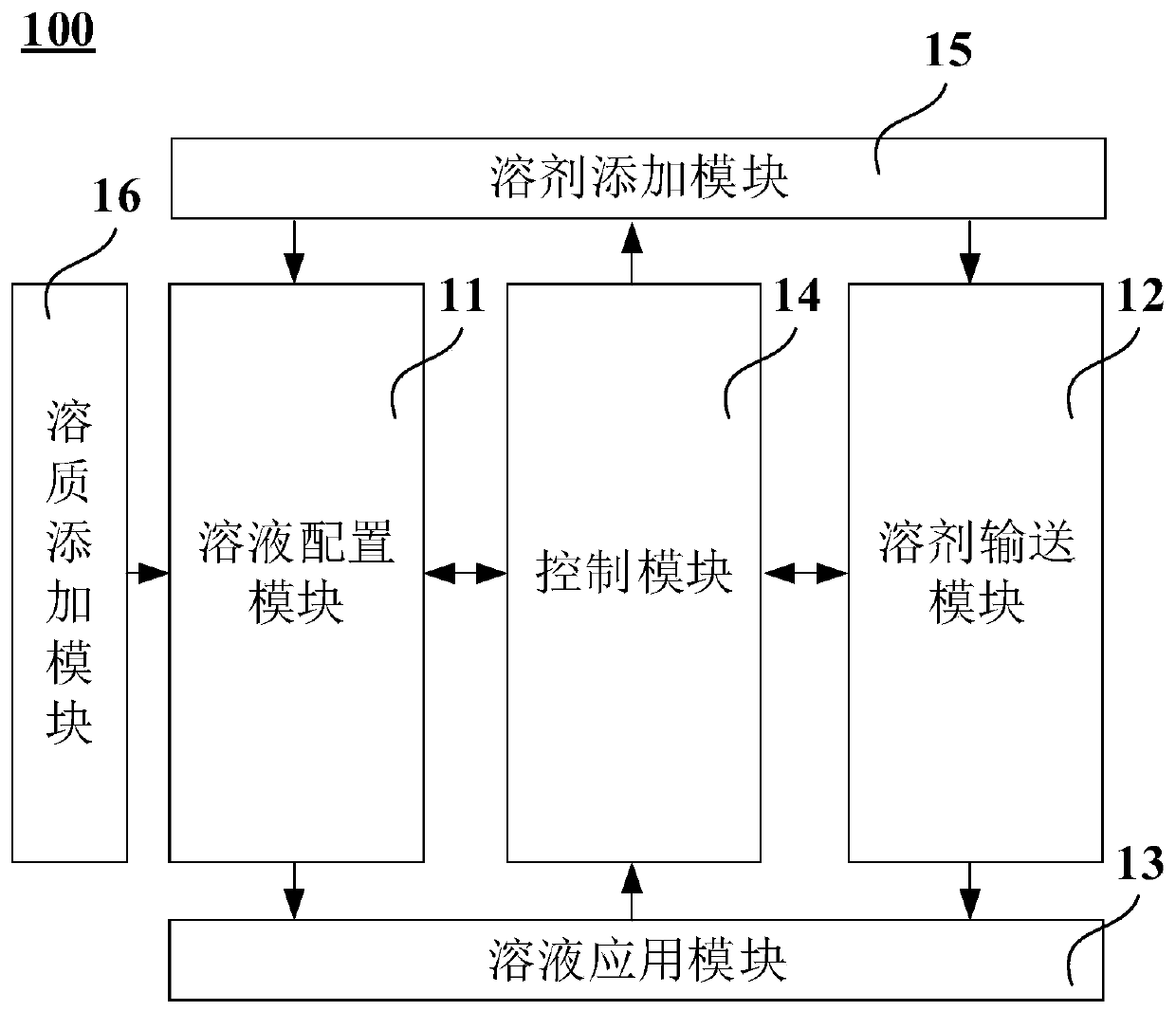

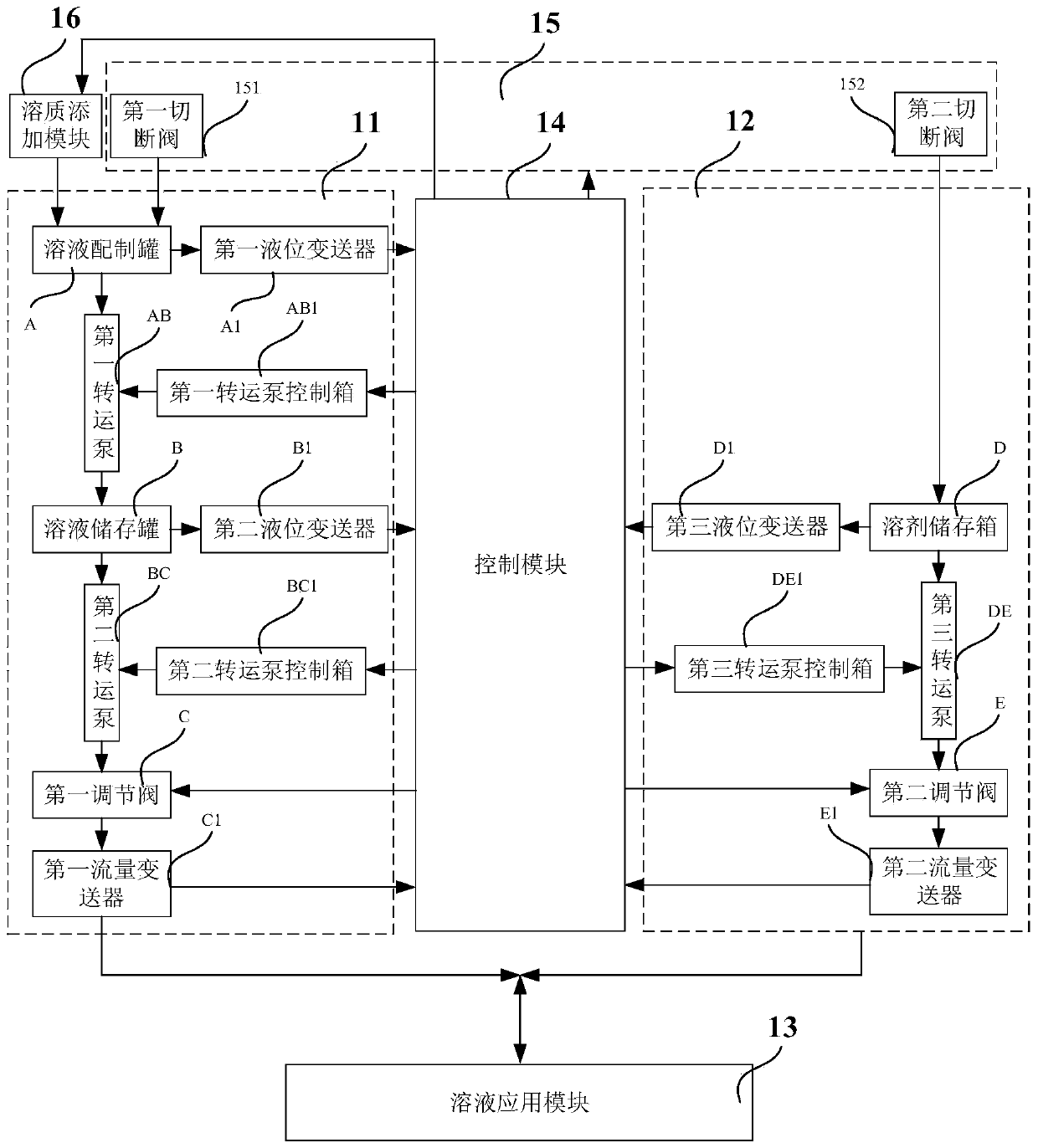

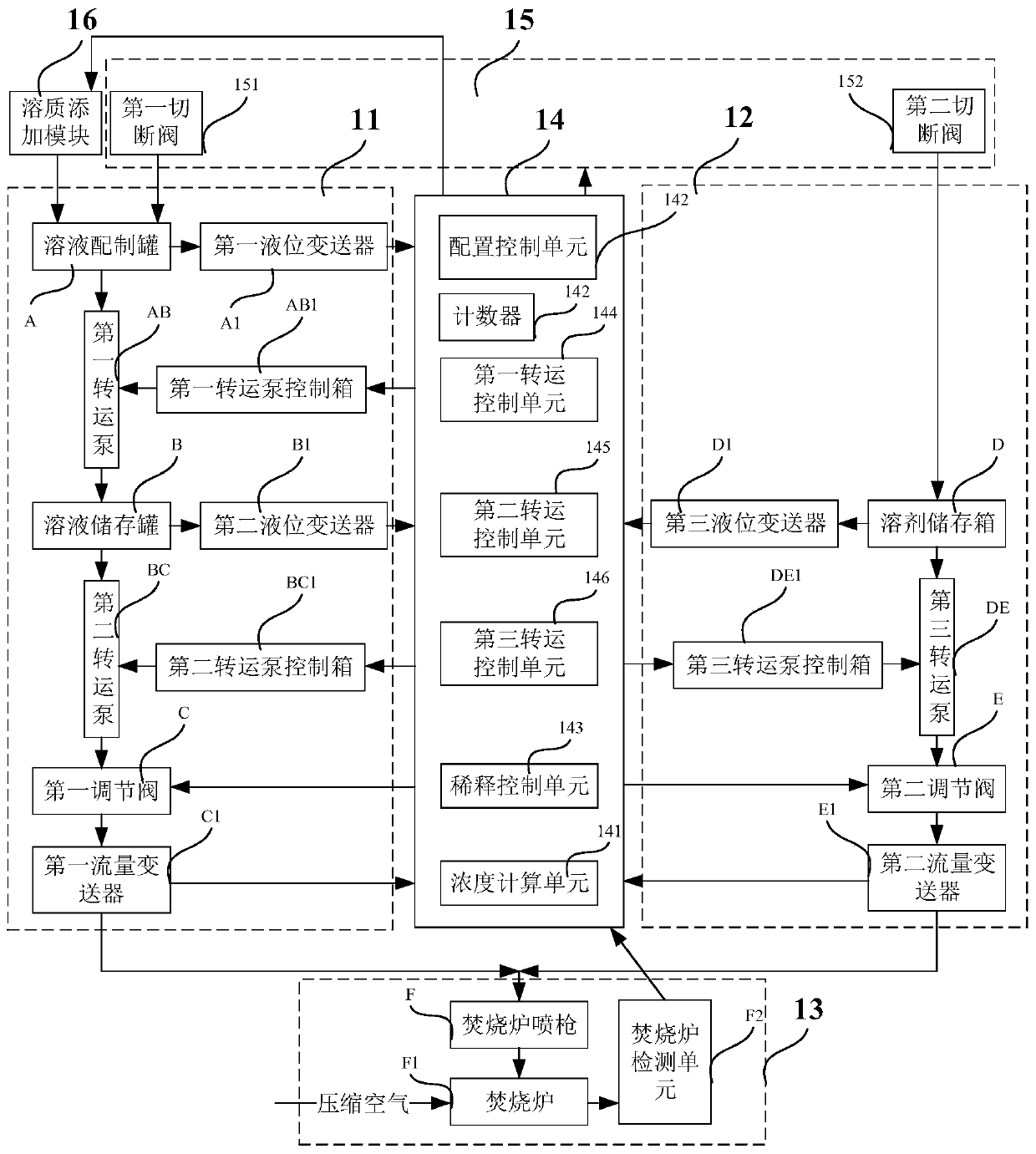

Denitration control system and method

PendingCN110152466AAvoid excessive additionLow costGas treatmentLighting and heating apparatusControl systemComputer module

The invention provides a denitration control system and method. The denitration control system comprises a solution preparation module, a solvent conveying module, a solution application module and acontrol module; the solution preparation module is coupled to the solvent addition module and a solute addition module and is used for preparing, storing and outputting a solution with a preset concentration; the solvent conveying module is coupled to the solvent addition module and is used for storing and conveying a solvent diluting the solution; the solution application module is coupled to thesolution preparation module and a solvent conveying module and is used for receiving the diluted solution and applying the diluted solution; and the control module is coupled to the solution preparation module, the solvent conveying module and the solution application module and is used for simultaneously controlling the material stock and output flow of the solution preparation module and the solvent conveying module according to the solution allowance index of the solution application module to control the input solution concentration of the solution application module so that the solutionallowance index reaches a preset value. According to the embodiment of the invention, material waste can be avoided under the condition that the solution is guaranteed to be sufficient.

Owner:CHINA ENFI ENGINEERING CORPORATION

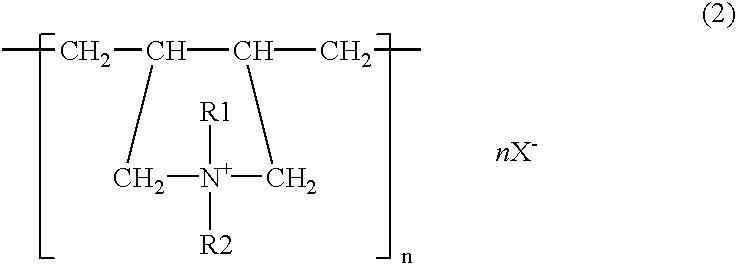

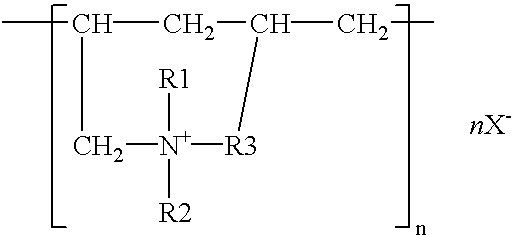

Surface treating method and surface treating agent

InactiveUS7030183B2Improve corrosion resistancePromote resultsOther chemical processesConductive materialAliphatic amineZinc

A plating solution containing zinc, an electrically conductive salt, an adsorbent, and at least one of mono- to hexavalent metal ions. A treatment using either a solution which contains, all per liter, 2–60 g Zn, 40–300 g caustic alkali, 0.01–50 g adsorbent, 0.002–10 g Fe, 0.002–10 g Co, 0.05–30 g Mn, 0.001–2 g Cu, 0.005–10 g Ni, 0.002–3 g of at least one chosen from among Mo, W, V, Ti, Al, Ca, Ba, and Sn, and 0.01–30 g aliphatic amine or aliphatic amine polymer or a solution which contains, all per liter, 2–40 g Zn, 40–170 g caustic alkali, 0.01–50 g adsorbent, either 0.001–3 g Fe and 0.001–3 g Co or 0.005–5 g Fe and 0.005–5 g Ni, and 0.01–30 g aliphatic amine or aliphatic amine polymer.

Owner:NIPPON HYOMEN KAGAKU KK

Quenching Fluid

InactiveUS20090308505A1Improve cooling effectHigh indexHydrocarbon by hydrogenationHydrocarbon purification/separationFluid compositionCentistokes

Quenching fluid composition comprising one or more additives and a saturated base oil having a kinematic viscosity at 100° C. “K” expressed in centistokes and a viscosity index “I” wherein I is greater than 120 and K greater than 2 cSt.

Owner:SHELL OIL CO

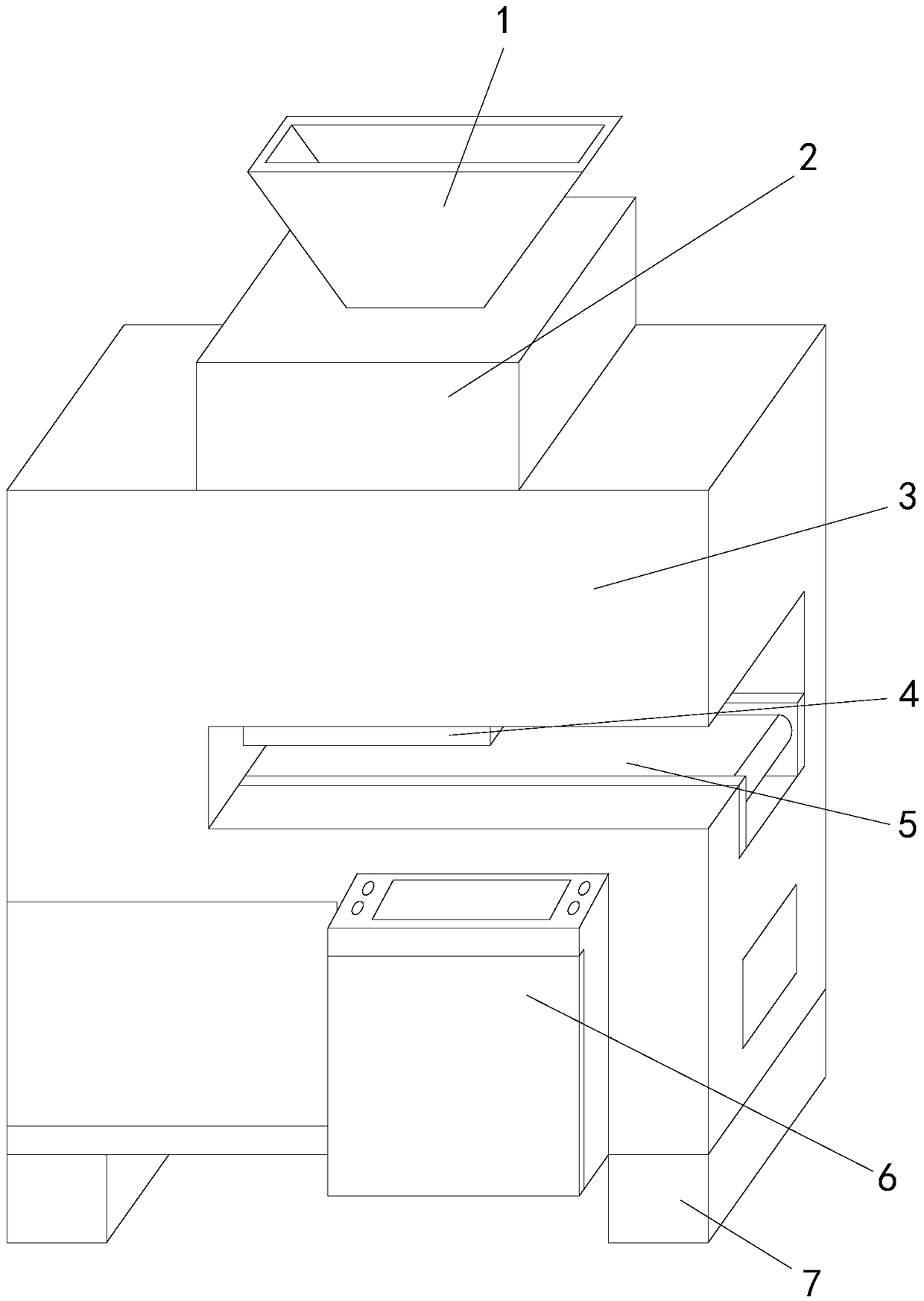

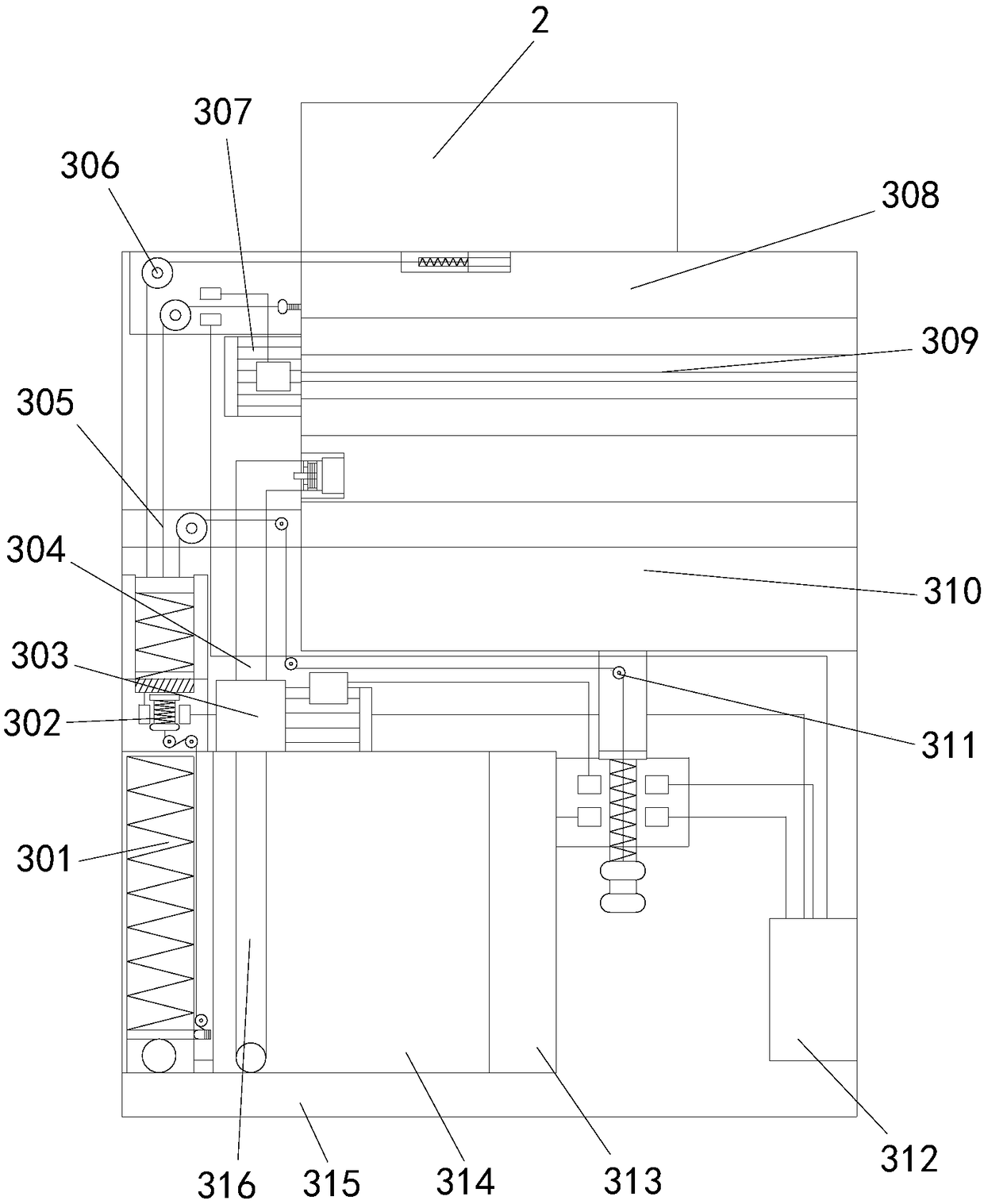

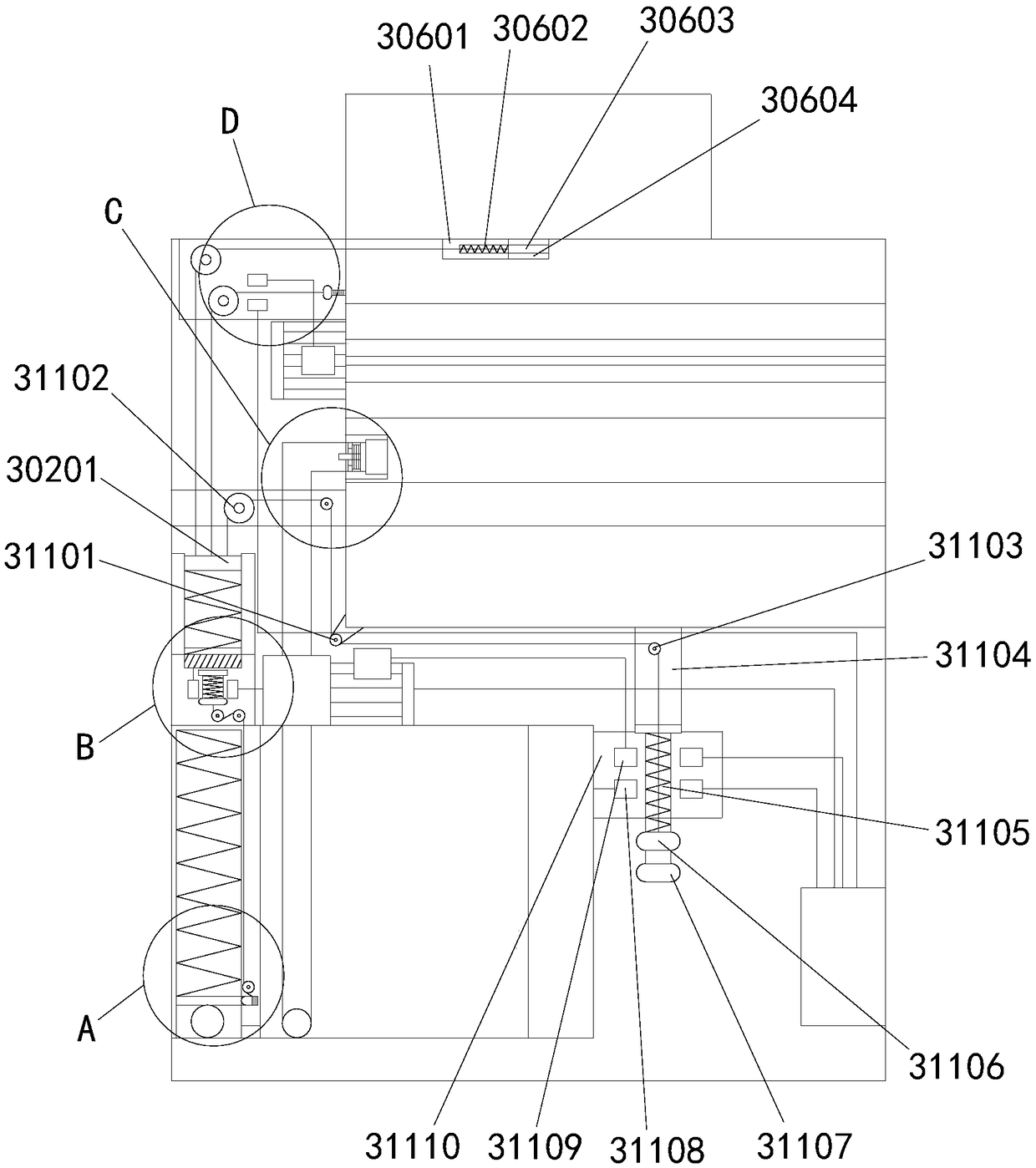

Conductive rubber production device

The invention discloses a conductive rubber production device. The conductive rubber production device structurally comprises a feeding hopper, a material storage box, a production machine body, a forming jacking pressure head, a production conveying belt, a controller and supporting plates, wherein the supporting plates are connected to the left side and the right side of the bottom end of the production machine body in a locked mode, the controller is connected to the lower part of the right side of the front end of the production machine body in a locked mode, the production machine body iselectrically connected to the controller, the material storage box is welded to the middle of the top end of the controller, and the material storage box is welded to the middle of the top end of theproduction machine body, the production machine body is communicated with the material storage box, the material storage box is a cuboid, the feeding hopper is welded to the middle of the top end ofthe production machine body, the production machine body is communicated with the feeding hopper, and the forming jacking pressure head is embedded to the production machine body in a locked mode. According to the conductive rubber production device, during use, through mechanisms such as pull ropes, a jacking block, springs and power connection plates which are arranged, when the raw materials ofrubber are sufficient, the device can automatically start feeding of conductive particles, heating and extracting of the raw materials and stirring after material mixing can be automatically carriedout, when the raw materials are insufficient, the device can automatically stop heating and extracting and stop feeding of the conductive particles, so that synchronous feeding of the conductive particles and the raw materials is guaranteed, excessive addition of the conductive particles is prevented, and the device is convenient to use.

Owner:刘福原

Covering and Method for Producing Coverings

ActiveUS20200208415A1Easy processabilityExcellent propertyConstruction materialLamination ancillary operationsMechanical engineeringFloor covering

The current invention concerns coverings such as a floor covering, wall covering or ceiling covering, said covering comprising at least one substrate and at least one surface layer, said surface layer comprising a print pattern and a wear layer, whereby said print pattern is directly applied to said substrate, and further concerns a method to produce such coverings.

Owner:BEAULIEU INT GRP NV

Heat treatment method of pin for endless track

InactiveUS9303297B2Improve productivityReduce manufacturing costFurnace typesIncreasing energy efficiencyProduction rateHeat treated

Owner:TOPY INDUSTRIES

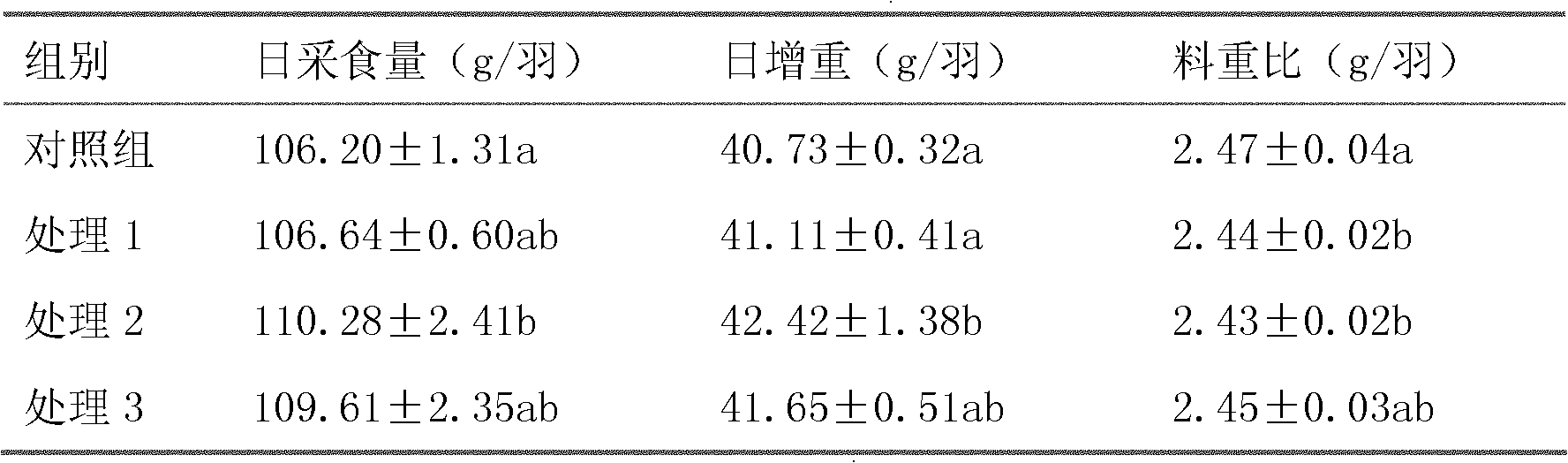

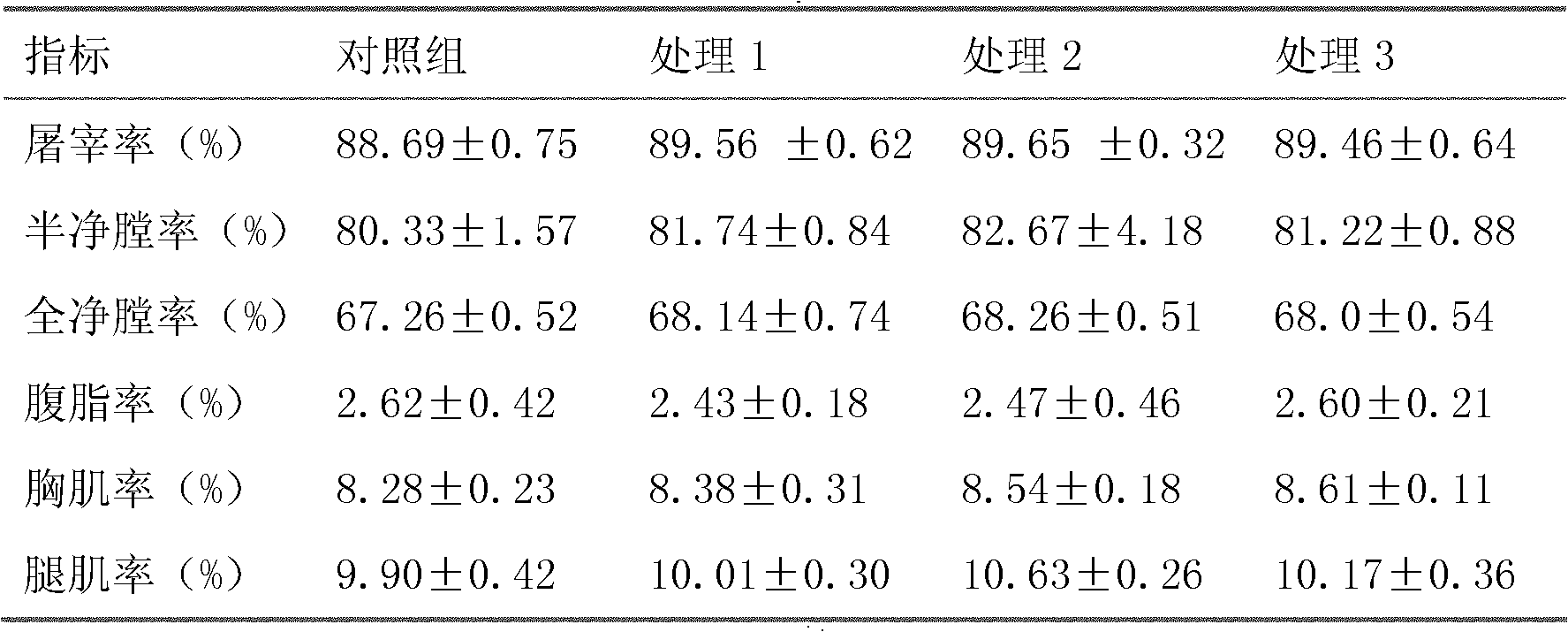

Mountain chicken feed containing giant knotweed rhizome residue and preparation method thereof

InactiveCN102090542AGood for healthImprove meat qualityAnimal feeding stuffWorking-up animal fodderGoniothalamusFlavor

The invention discloses a mountain chicken feed containing giant knotweed rhizome residue, the mountain chicken feed is prepared by adding the giant knotweed rhizome residue into a basic ration for mountain chickens, wherein the adding amount of the giant knotweed rhizome residue is 5wt%-15wt% of the basic ration for the mountain chickens. The invention further discloses a preparation method of the mountain chicken feed. The mountain chicken feed provided by the invention is prepared through the following steps: performing drying and crushing processing treatment on waste residue obtained by extracting juice from giant knotweed rhizome; then preparing giant knotweed rhizome residue powder; and finally adding the giant knotweed rhizome residue powder into the basic ration for the mountain chickens. The mountain chicken feed can be used for improving the health condition of the mountain chickens, improving the chicken quality and flavor of the mountain chickens, reducing the feeding cost of the mountain chickens and upgradng the economic benefits of the mountain chickens.

Owner:AGRI BIO TECH INST GUANGDONG ACADEMY OF AGRI SCI +2

Organic composite trace element and preparation method thereof

PendingCN114747668AEnhanced ChelationAvoid excessive additionAccessory food factorsResistant starchTrace element

The invention relates to the technical field of material processing, and aims to solve the problem of low chelation degree of chitosan mentioned in the prior art. The invention provides an organic-inorganic composite trace element and a preparation method thereof, the organic-inorganic composite trace element comprises a ligand and a trace element, and the ligand and the trace element are chelated to obtain the organic composite trace element; the ligand is a resistant starch-chitosan graft. The preparation method comprises the following steps: grafting resistant starch and chitosan to obtain a graft; the chelating degree of ligands and trace elements is improved; the resistant starch is difficult to be directly digested and utilized by hosts and can promote growth of intestinal probiotics and absorption of mineral substances; by forming the graft, the chelating degree of the chitosan is improved, and meanwhile, the physiological function regulation and control of animal organisms are also facilitated.

Owner:CHENGDU SHUXING FEED

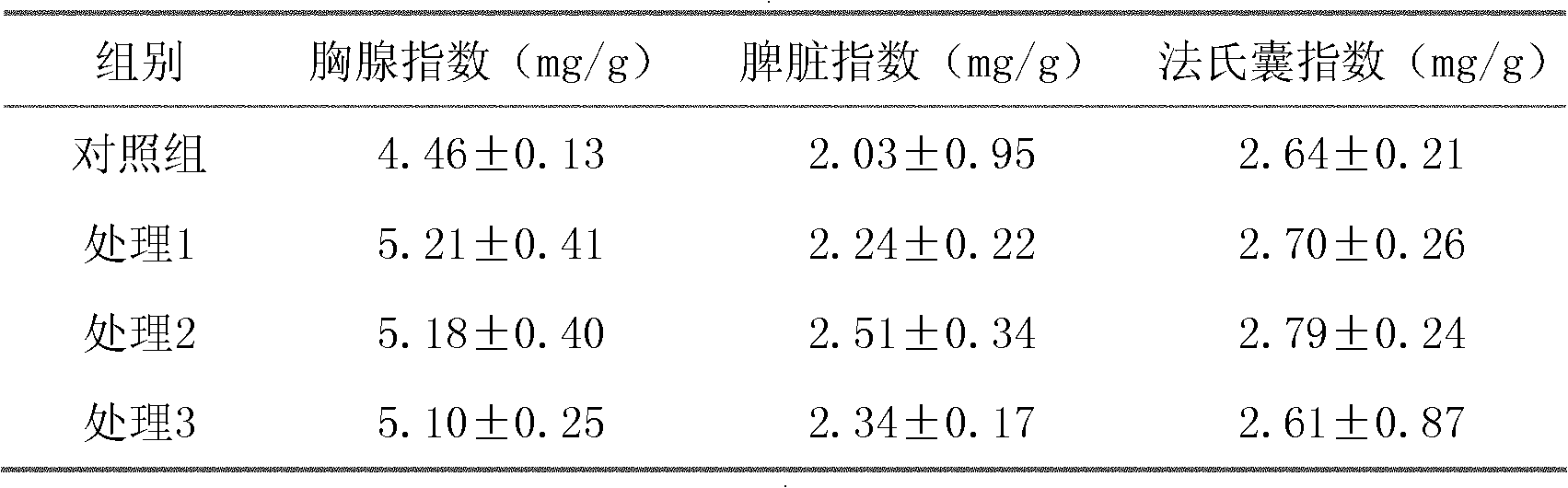

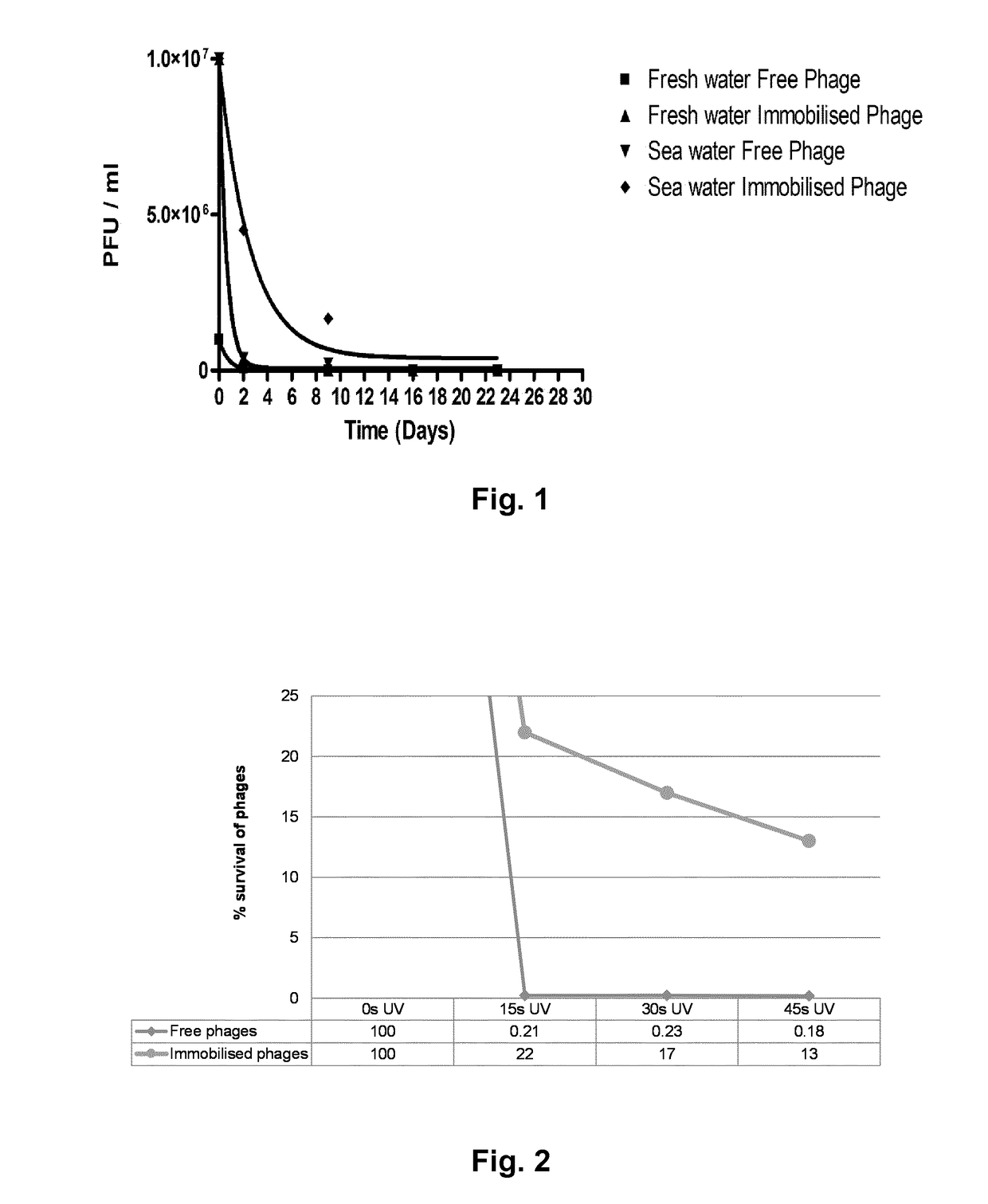

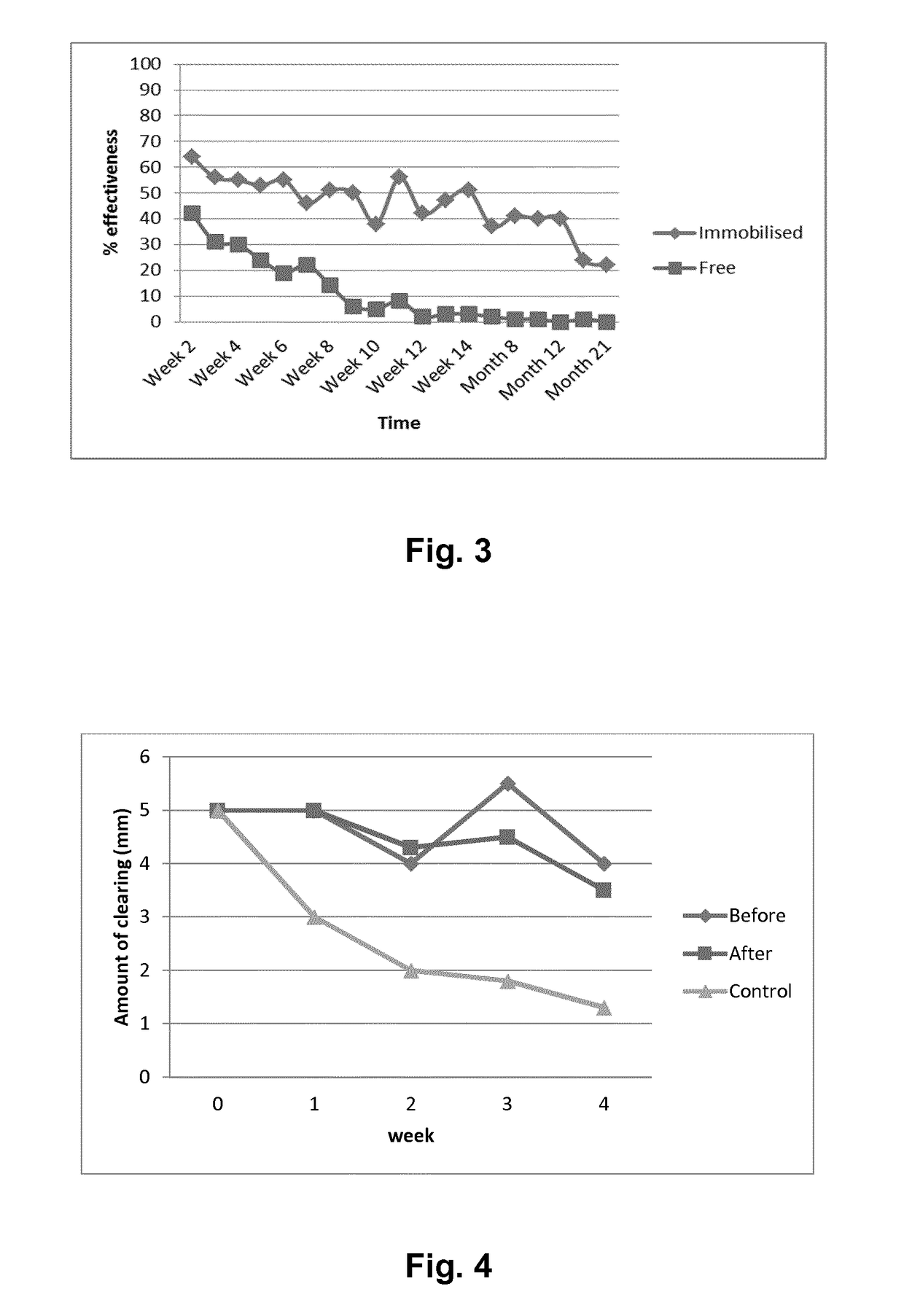

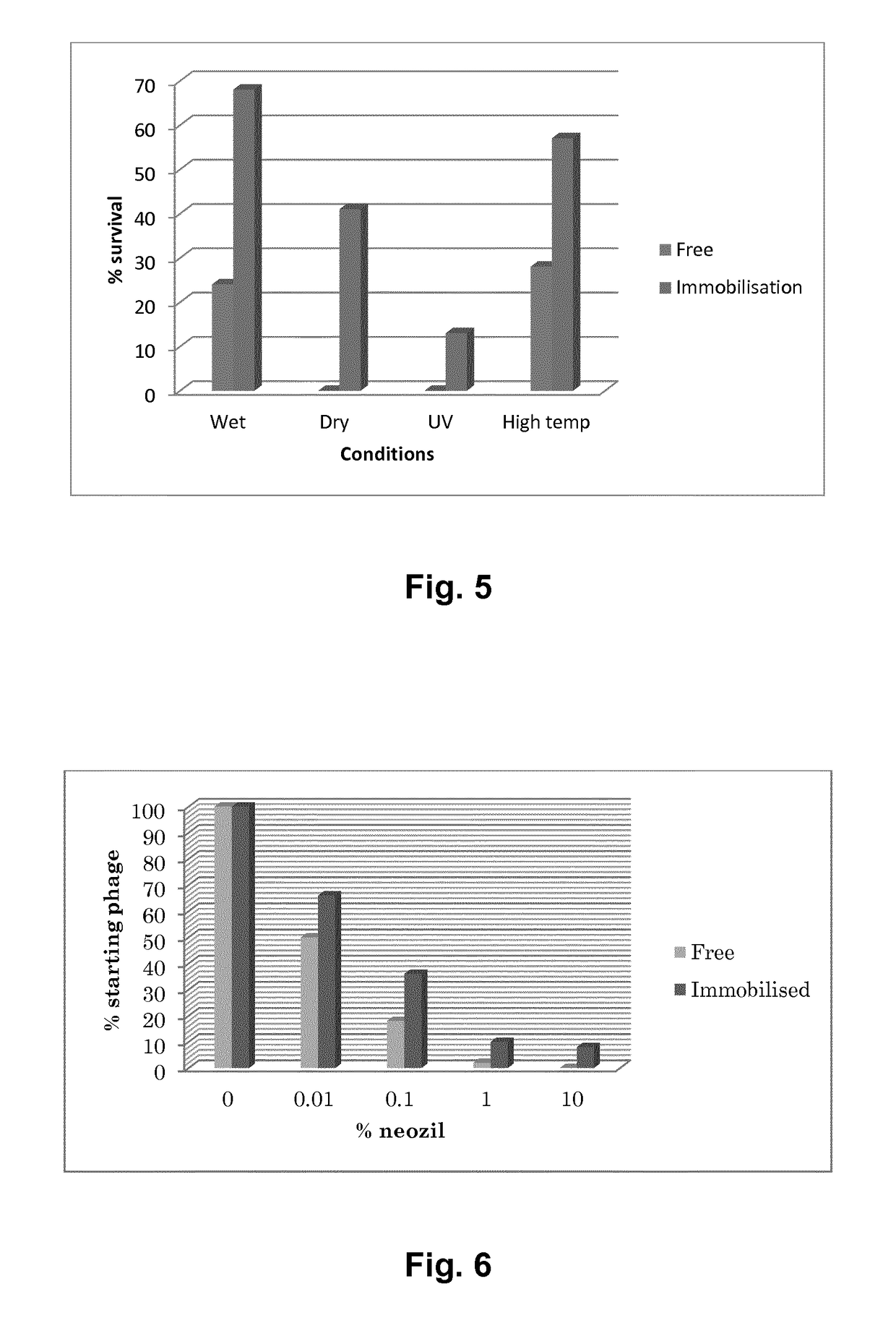

Treatment of bacterial infections in aquaculture

ActiveUS20180110812A1Improve stabilityImprove viabilityAntibacterial agentsPowder deliveryDiseaseBacteroides

A composition comprises bacteriophage covalently attached to an edible particle and is for use in treating bacterial infection in fish or crustaceans. Infections in fish or crustaceans caused by Vibrio, Aeromonas, Yersinia, Moritella, Rickettsia, Piscirickettsia, Lactococcus, Pseudomonas, Flavobacterium or Photobacterium bacteria species can be treated. Bacteria infected with a lysogenic bacteriophage are used for treating disease of fish or crustaceans caused by similar infections by bacteria carrying lysogenic bacteriophage that express a toxin gene.

Owner:FIXED PHAGE

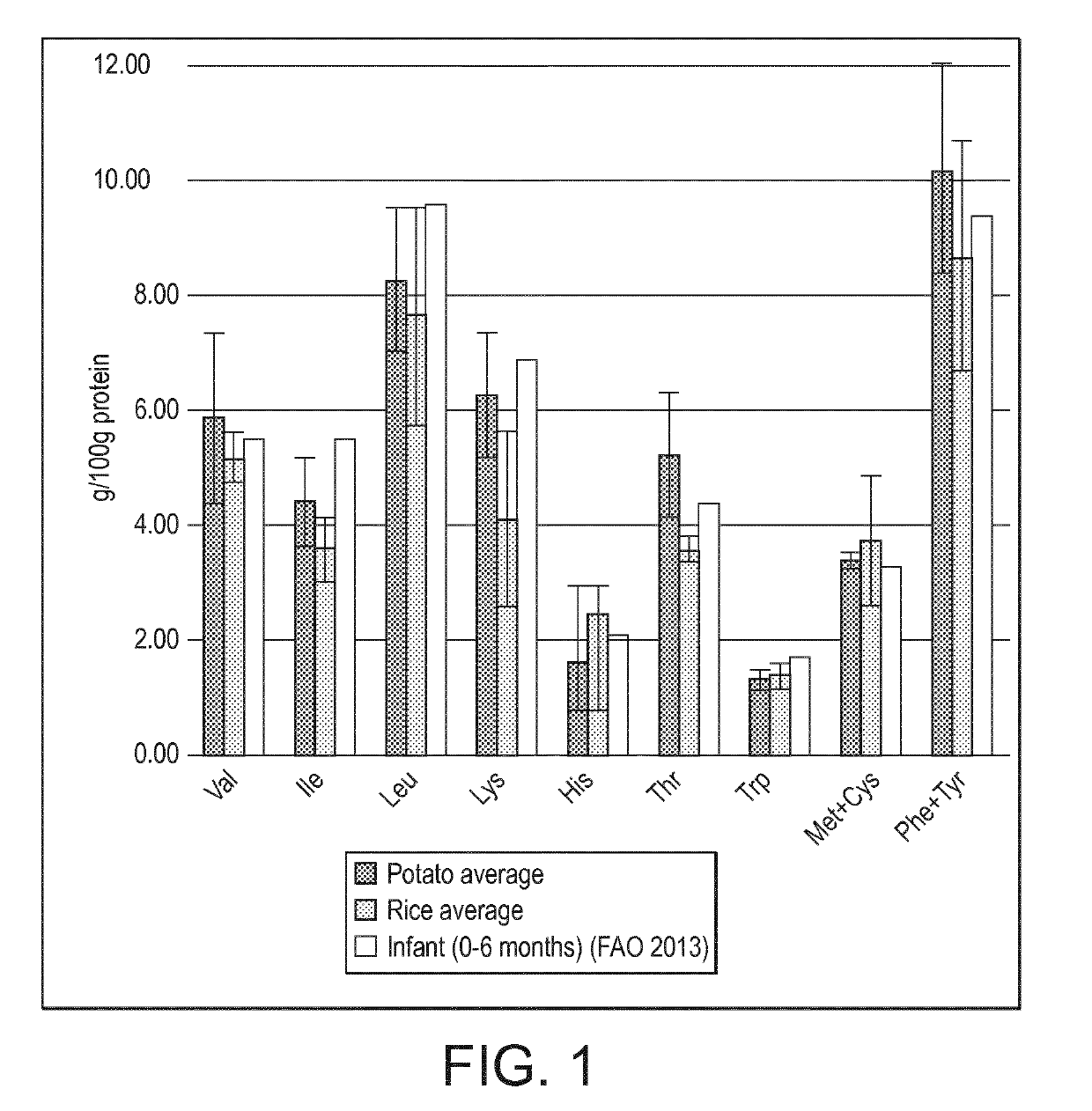

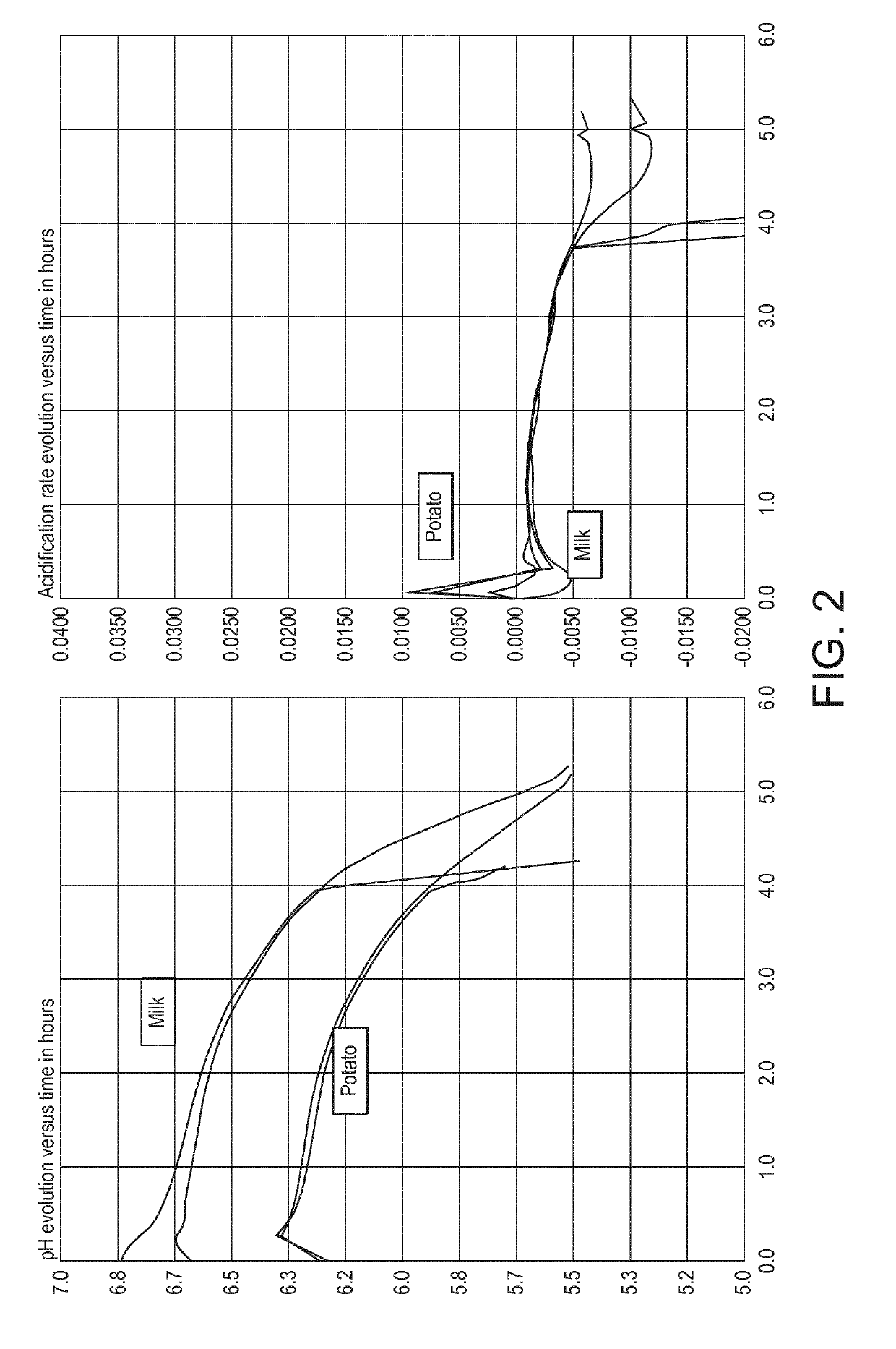

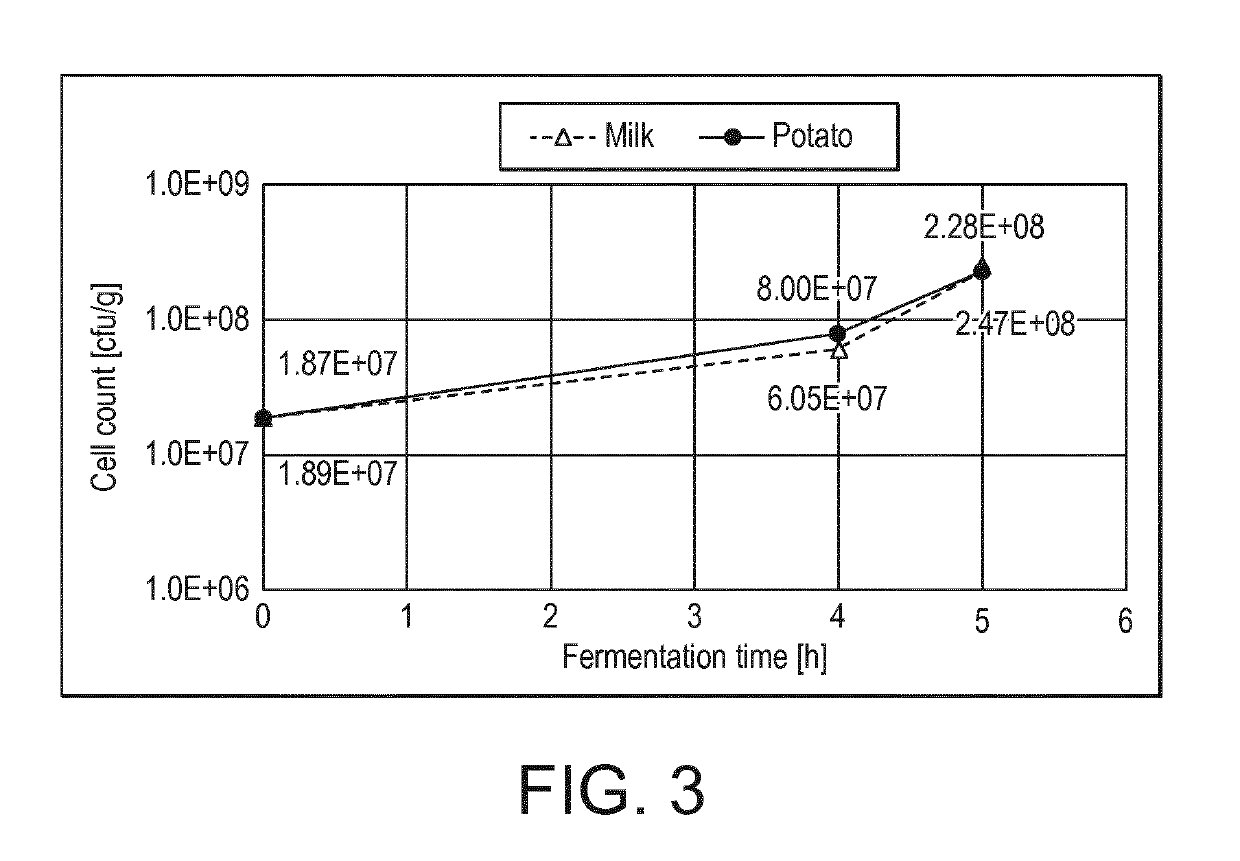

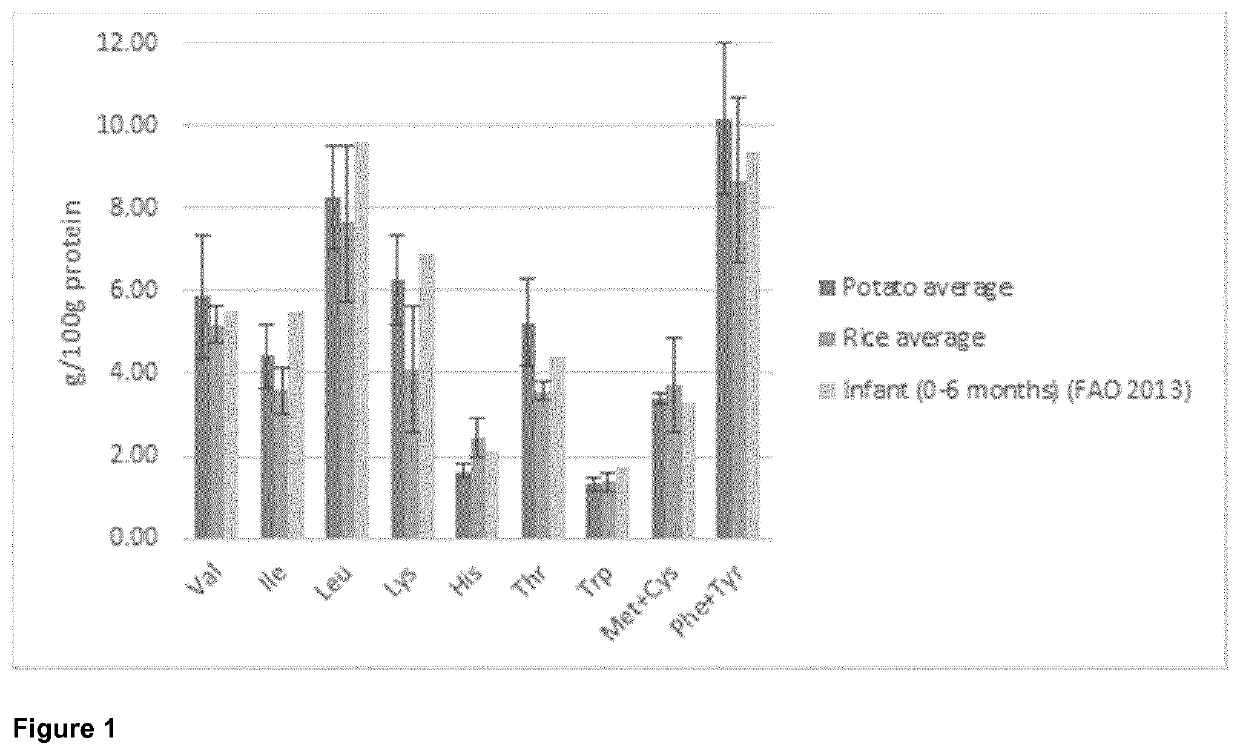

Fermented nutritional composition for cow's milk protein allergic subjects

ActiveUS20190246680A1Different tasteBeneficial effect incidenceMilk preparationLactobacillusNutritional compositionLactic acid producing bacteria

A nutritional composition obtainable by fermenting a mixture comprising protein, carbohydrate and fat, wherein the major source of protein is potato protein, and wherein the mixture is fermented by lactic acid-producing bacteria.

Owner:SOC DES PROD NESTLE SA

Method for adding lutein ester during food manufacture

InactiveCN101336742AReduce high temperature oxidationReduce denaturationMilk preparationFood preparationLiquid stateFood processing

The present invention relates to a method for adding lutein esters into foods, belonging to food processing field. The method comprises the steps of adding sterile lutein esters into sterilized food base material of liquid state under aseptic condition. The present invention also relates to a method for producing a food added with lutein esters, which comprises the steps that bactericidal processing is performed for food base material of liquid state, and sterile lutein esters preparation is added into sterilized food base material of liquid state. In the present invention, the loss of lutein esters in food processing can be reduced, the loss of health function of lutein esters caused by oxidation can be prevented, and the amount of addition of lutein esters can be decreased.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

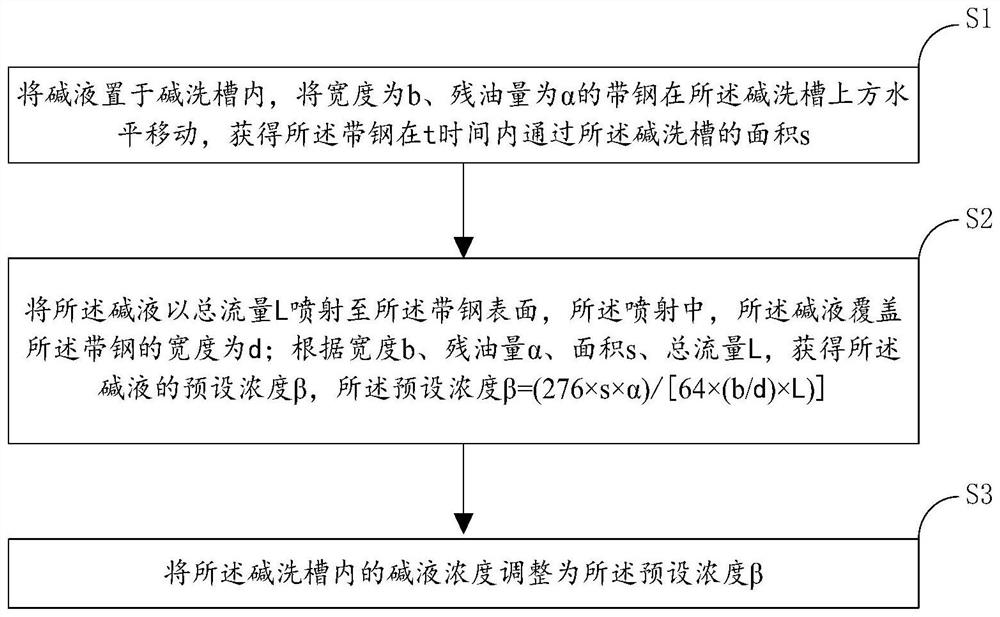

Strip steel cleaning method capable of reducing alkali liquor consumption

ActiveCN113416962AReduce consumptionReduce effluxProcess efficiency improvementSocial benefitsProcess engineering

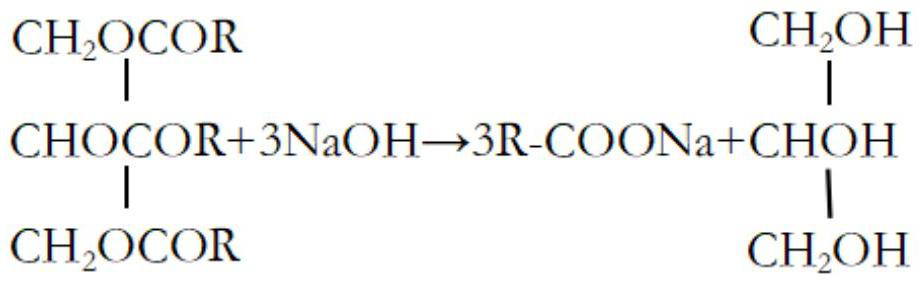

The invention discloses a strip steel cleaning method capable of reducing alkali liquor consumption. The method comprises the following steps that the alkali liquor is placed in an alkaline bath, strip steel with the width of b and the residual oil quantity of alpha is moved horizontally above the alkaline bath, and the area s of the strip steel passing through the alkaline bath within the time t is obtained; the alkali liquor is sprayed to the surface of the strip steel at the total flow L, and the covering width of the alkali liquor in the spraying process is d; in the spraying process, the preset concentration beta of the alkali liquor is obtained according to the width b, the residual oil quantity alpha, the area s and the total flow L; and the concentration of the alkali liquor in the alkaline bath is adjusted to be the preset concentration beta. An inventor analyzes overhigh consumption of the alkali liquor, and dynamically matches the concentration of the alkali liquor according to a saponification reaction principle, so that the purpose of reducing the consumption of the alkali liquor is achieved; the consumption of the alkali liquor can be effectively reduced, and the process cost is reduced; and moreover, the discharge of dangerous chemicals such as the alkali liquor can be reduced, and the method has great significance for increasing the economic and social benefits of enterprises.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

Method for rapidly evaluating usage amount of silica gel and PVPP (Crosslinked Polyethylene Pyrrolidone) by using charge titration technique

ActiveCN103575851BQuality improvementReduce manufacturing costChemical analysis using titrationFiltrationCross-linked polyethylene

The invention relates to a method for evaluating the application of a stabilizing auxiliary in a beer filtration process, and in particular relates to a method for rapidly evaluating the usage amount of silica gel and PVPP (Crosslinked Polyethylene Pyrrolidone) by using a charge titration technique. Charges of colloidal particles of sensitive protein and sensitive polyphenol in beer are negative, the charges of silica gel and PVPP are positive, and along with the increase of the usage amount of the silica gel and the PVPP, the charges of the colloidal particles in the beer are gradually converted into positive charges from negative charges. The addition amount of the silica gel and the PVPP of which the number of the charges is approximate to 0 is taken as the optimal usage amount of the silica gel and the PVPP. According to the method, by evaluating the charge situation of the colloidal particles of the silica gel and the PVPP of the beer, the optimal action condition and optimal usage proportion of the beer stabilizing auxiliaries can be effectively determined. Therefore, the application of the stabilizing auxiliary can be rapidly optimized, and the purposes of stabilizing the quality of the beer and lowering the production cost are achieved.

Owner:TSINGTAO BREWERY

High protein puffed whole egg snack

ActiveUS20180242621A1High protein content compositionImprove the extrusion effectProteins working-up by texturisingFood shapingWhey proteinSnack food

A snack food is prepared by a unique process comprising extruding an extrusion composition under heat and pressure to form an expanded, cooked, egg and added-protein snack food, wherein the extrusion composition comprises a) whole liquid egg present in an amount of from about 5 to about 25% by weight based on the total weight of the extrusion composition, b) an added protein concentrate or isolate selected from the group consisting of rice protein, soy protein, whey protein or mixtures thereof, in an amount so that the total protein present in the expanded, cooked, egg and added-protein snack food is from about 25 to about 40% by weight, and c) starch in an amount sufficient to provide an expanded, cooked, egg and added- protein snack food having a density no greater than about 300 grams per cubic inch.

Owner:CARGILL INC

Method for producing a nutritional composition

ActiveUS11109616B2Improve usabilityReduce processFood preservationImmunological disordersBiotechnologyNutrition

A method for producing a nutritional composition comprising the steps: (a) providing a solution comprising at least one mineral for a nutritional composition; (b) adding at least one potato protein to the solution of step (a); (c) adding at least one carbohydrate and / or at least one fat to the solution of step (b); and (d) spray drying the solution of step (c).

Owner:SOC DES PROD NESTLE SA

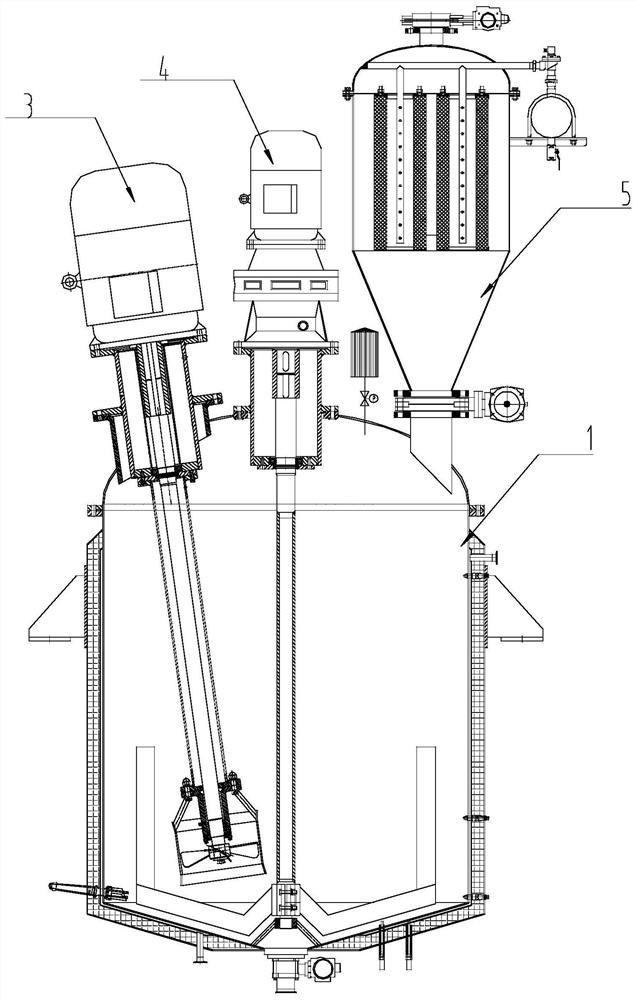

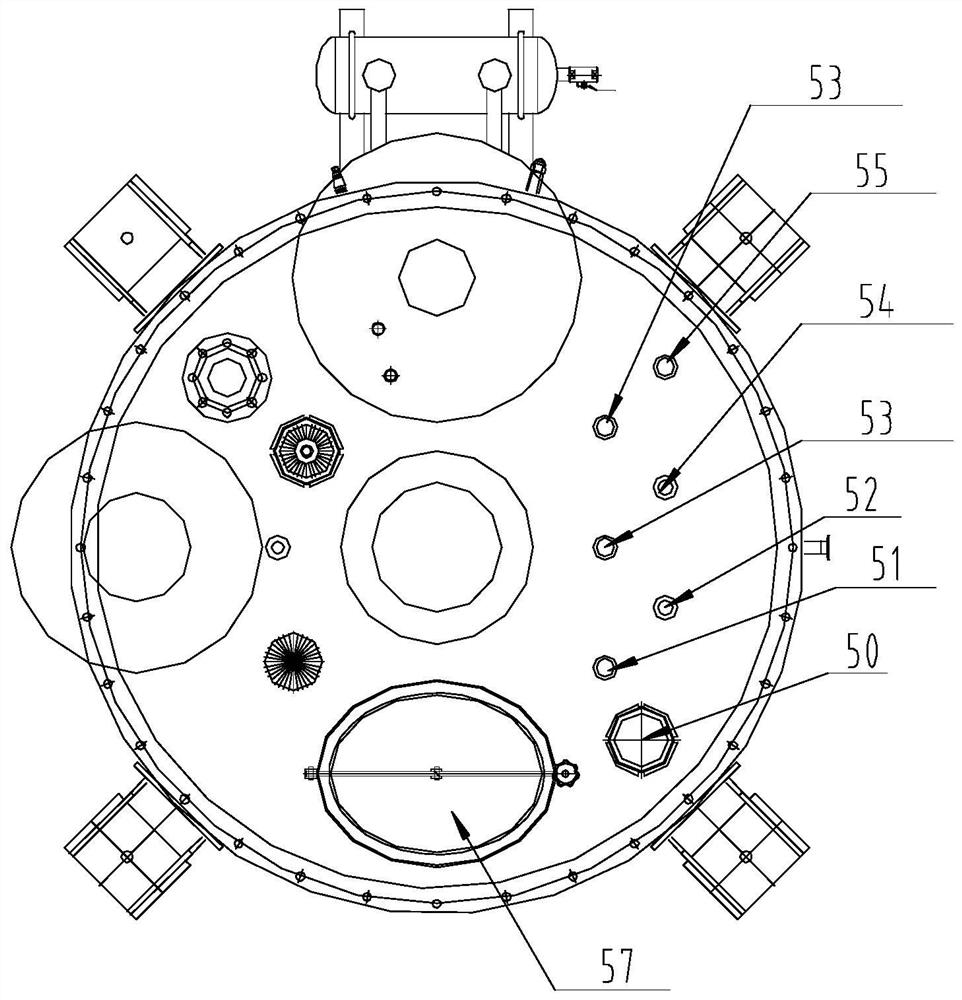

Negative-pressure powder feeding dust-free dual-power pulping kettle

PendingCN113289523AImprove the heating effectImprove cooling effectRotary stirring mixersTransportation and packagingHoneycombProcess engineering

The invention relates to a negative-pressure powder feeding dust-free dual-power pulping kettle which comprises a pulping kettle body, a kettle cover is arranged on the pulping kettle body, a high-speed stirring device, a low-speed stirring device and a gas-material separator are connected to the kettle cover, and a heat preservation mechanism is arranged on the outer surface of the pulping kettle body. The heat preservation mechanism comprises an inner container, a honeycomb plate jacket, heat preservation rock wool and a heat preservation jacket which are sequentially arranged from inside to outside, and an upper liquid level meter, a middle liquid level meter and a lower liquid level meter are sequentially connected to the side walls of the heat preservation mechanism and the pulping kettle body from top to bottom in a matched mode and communicate with the interior of the pulping kettle body. According to the invention, the gas-material separator is arranged on the pulping kettle body, so that dust-free addition of materials can be well realized, harm to a human body and pollution to the environment are reduced to a great extent, and explosion accidents caused by the dust problem are completely eradicated.

Owner:上海富昶环保科技有限公司

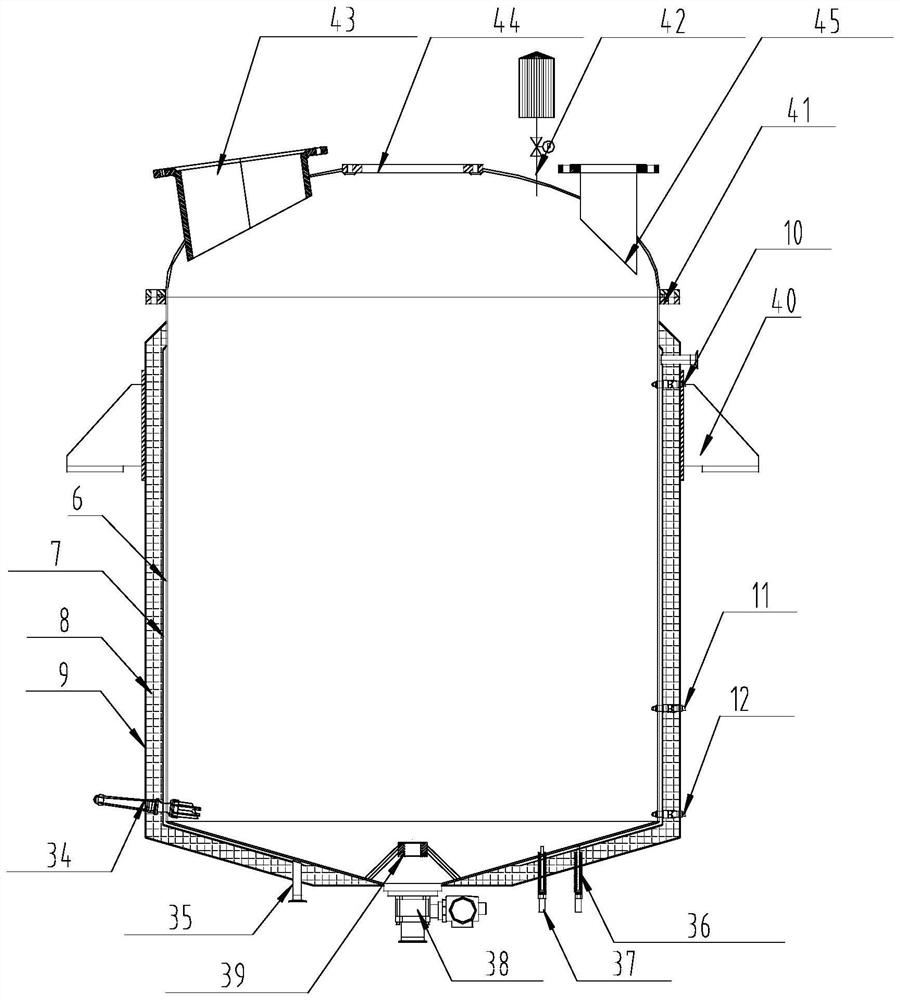

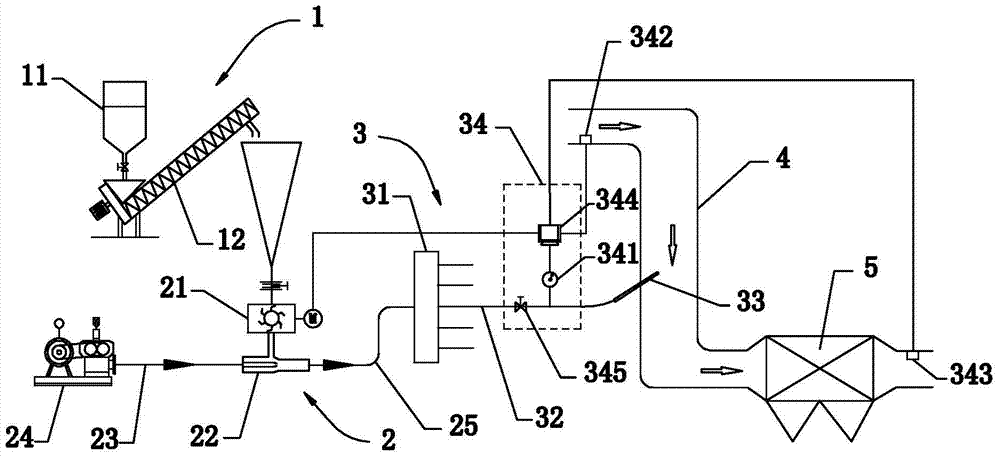

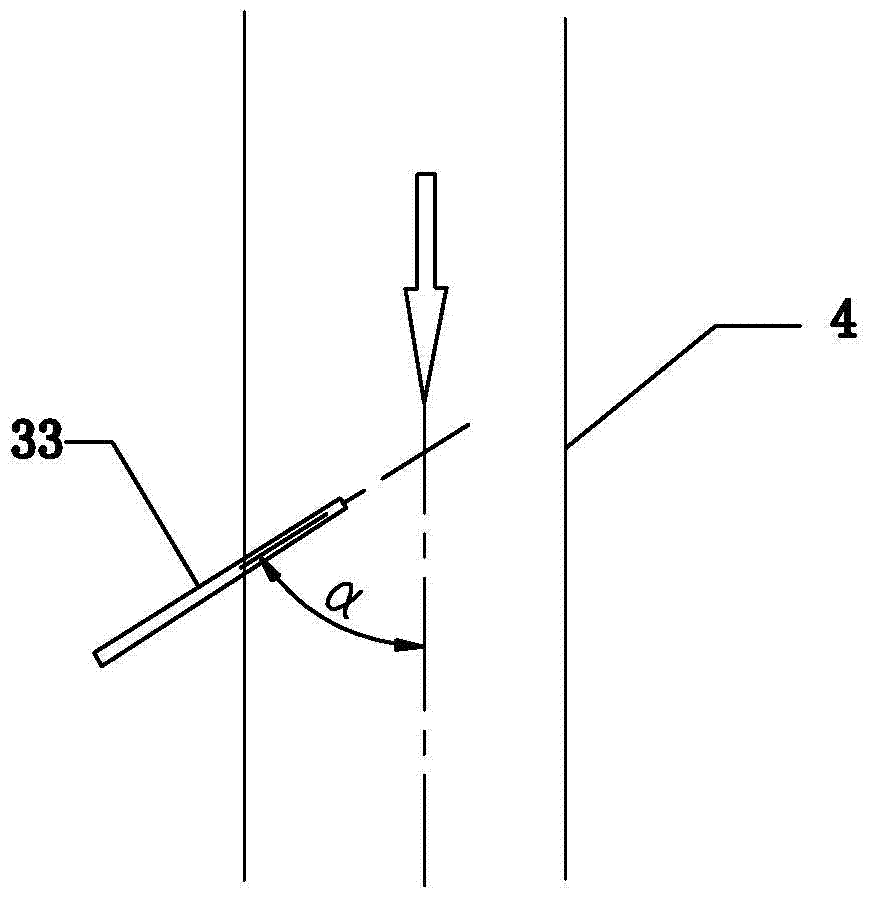

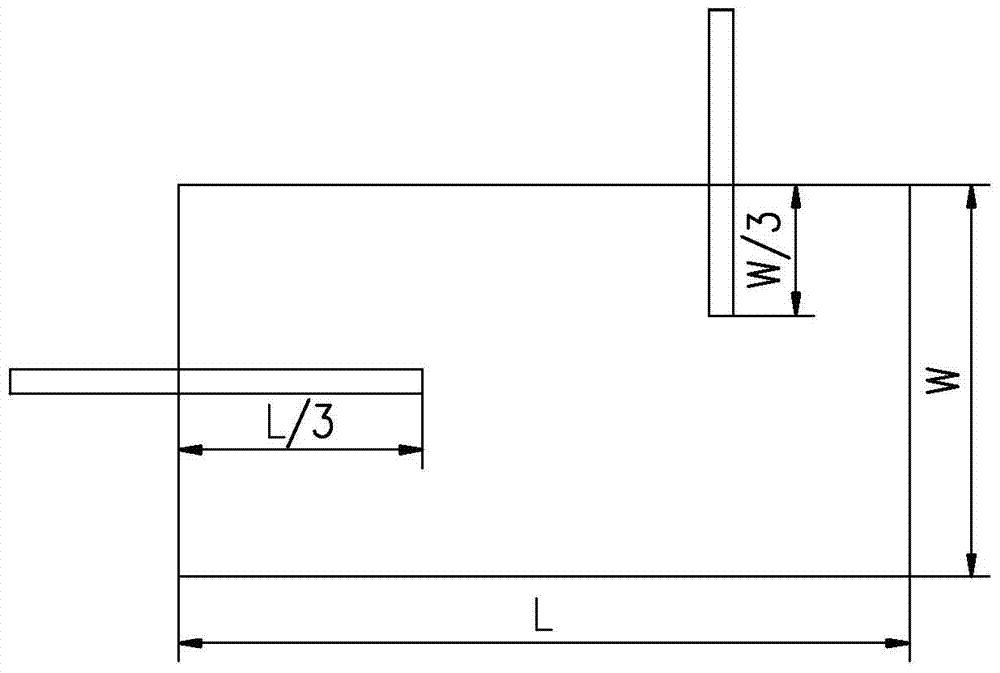

A coal-fired flue gas powder adsorbent injection mercury removal device

ActiveCN105126540BQuickly adjust the dosing ratioAvoid excessive additionDispersed particle separationFlue gasControl system

The invention belongs to the technical field of coal-fired flue gas purification, and in particular relates to a coal-fired flue gas powder adsorbent injection mercury removal device, which includes an adsorbent feeding part, an adsorbent powder conveying part and an adsorbent distribution injection part, wherein, The adsorbent feeding part includes a storage tank and a screw feeder; the adsorbent powder conveying part includes a frequency conversion feeder, a fan and an injector, and the ejector material is connected to the material conveying pipeline; The powder distributor is connected to several injection pipelines, and the injection pipeline is equipped with a spray gun and an intelligent flow control system. The invention can automatically and quickly adjust the dosing ratio of the powder adsorbent according to the mercury content in the flue gas, avoiding excessive or insufficient addition of the powder adsorbent, improving the effect of spraying mercury removal, reducing the waste of the powder adsorbent, and improving the The use efficiency of powder adsorbent reduces the cost of mercury removal.

Owner:山东默锐环境产业股份有限公司

Covering and method for producing coverings

ActiveUS11499321B2Good effectCost effectiveConstruction materialLamination ancillary operationsMechanical engineeringFloor covering

The current invention concerns coverings such as a floor covering, wall covering or ceiling covering, said covering comprising at least one substrate and at least one surface layer, said surface layer comprising a print pattern and a wear layer, whereby said print pattern is directly applied to said substrate, and further concerns a method to produce such coverings.

Owner:BEAULIEU INT GRP NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com