Negative-pressure powder feeding dust-free dual-power pulping kettle

A dual-power, pulping technology, used in dissolving, mixers, chemical instruments and methods, etc., can solve problems such as shortening the service life of components, environmental workshop pollution, excessive addition, etc., to improve heat exchange efficiency, prevent explosion accidents, The effect of stirring evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

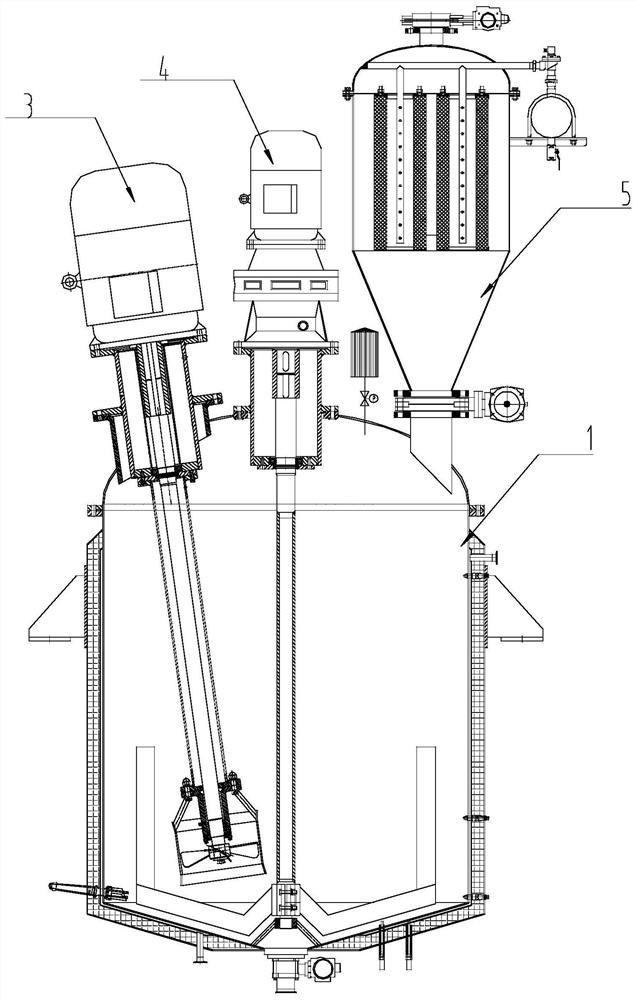

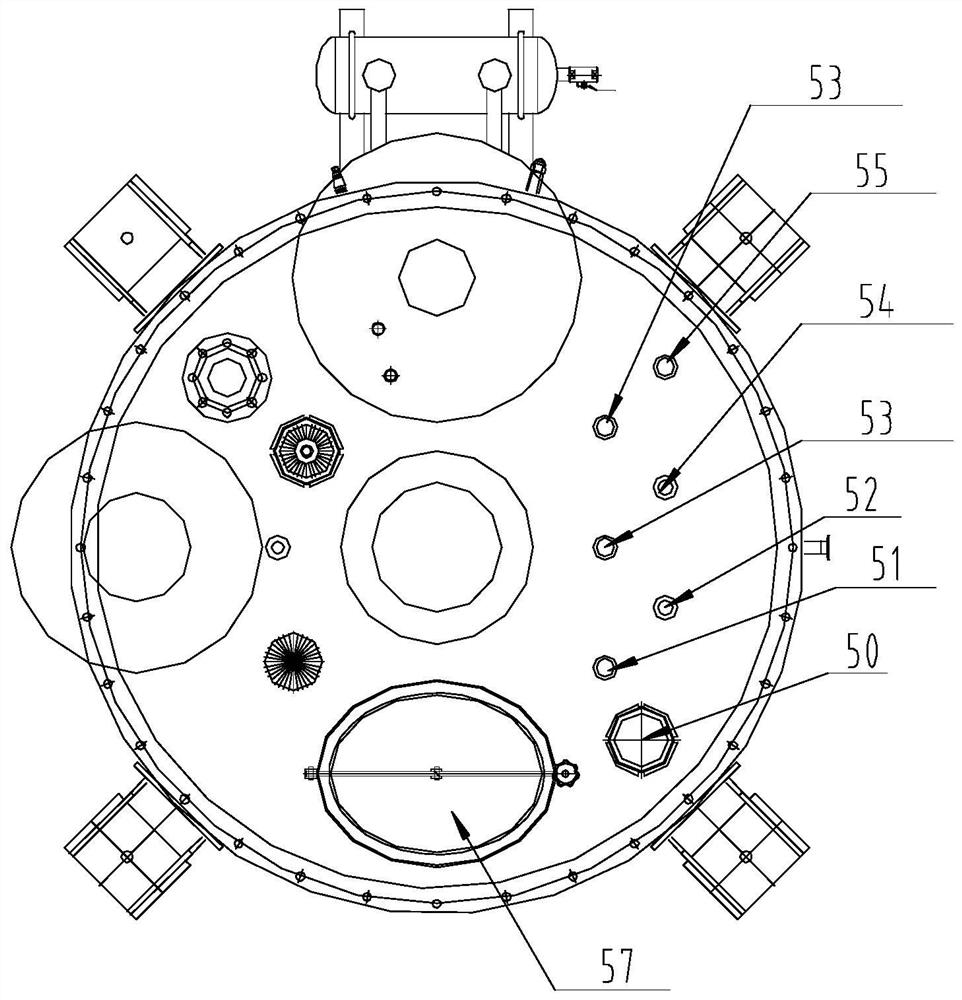

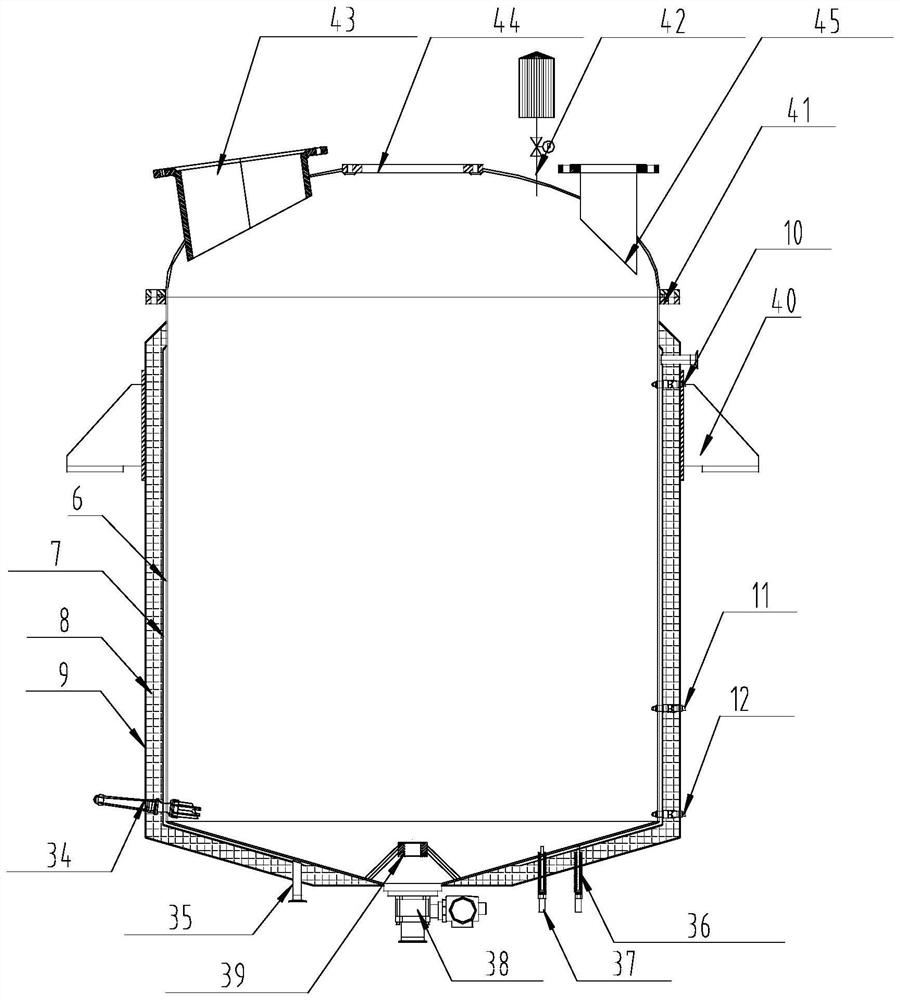

[0030] see Figure 1 to Figure 6 , in the embodiment of the present invention:

[0031] A dust-free dual-power pulping kettle with negative pressure feeding powder, comprising a pulping kettle body 1, a kettle cover 2 is arranged on the pulping kettle body 1, and a high-speed stirring device 3, a low-speed stirring device 4 and a gas mixing device are connected to the kettle cover 2. The material separator 5, the outer surface of the pulping kettle body 1 is provided with a thermal insulation mechanism, and the thermal insulation mechanism includes an inner tank 6, a honeycomb panel jacket 7, a thermal insulation rock wool 8 and a thermal insulation jacket sequentially arranged from the inside to the outside. 9. The heat preservation mechanism and the side wall of the pulping kettle body 1 are sequentially connected with an upper liquid level gauge 10, a middle liquid level gauge 11 and a lower liquid level gauge 12, which are connected with the pulping kettle body 1 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com