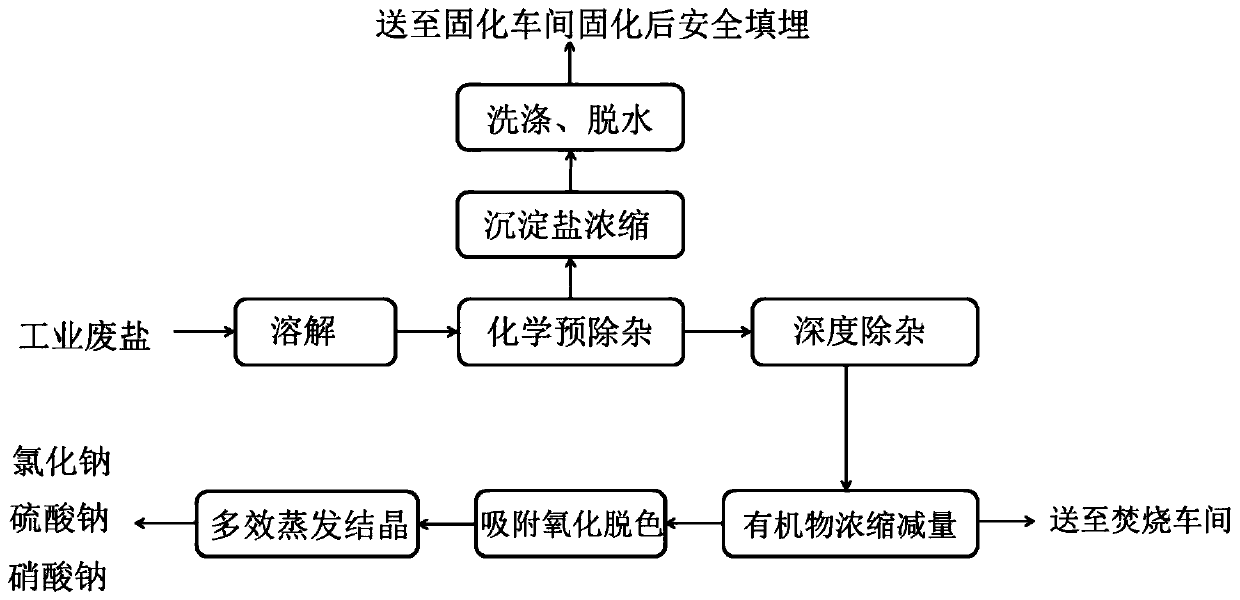

Industrial waste salt resourceful treatment method and equipment

A technology of industrial waste salt and treatment method, which is applied in the direction of shape preparation of alkali metal halides, purification of alkali metal halides, purification of alkali metal nitrates, etc., can solve problems such as inability to be effectively utilized, reduce difficulty and cost, and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

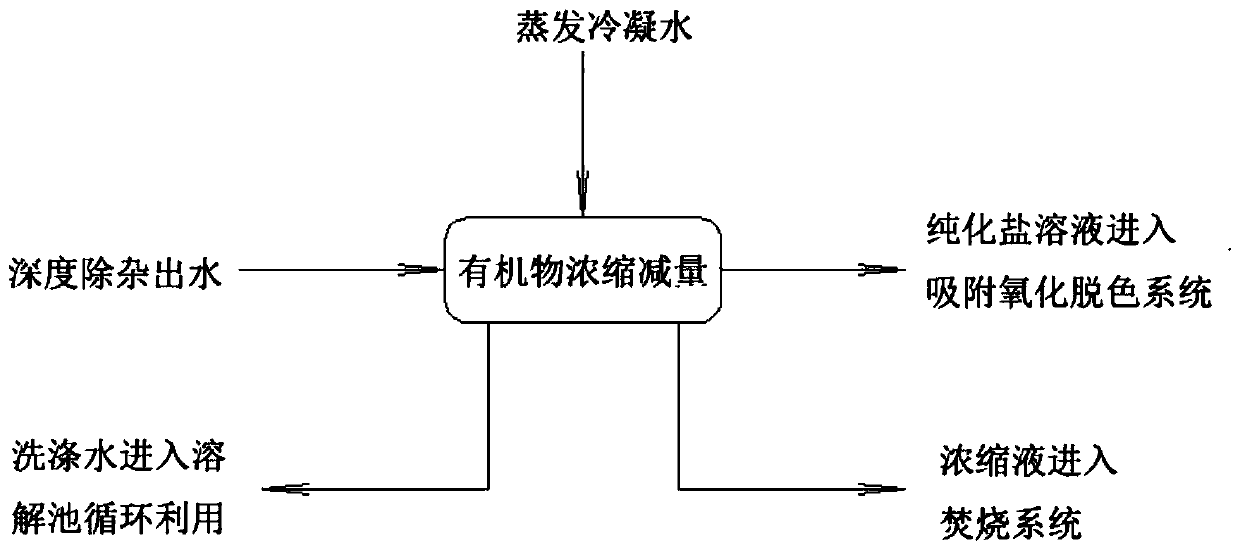

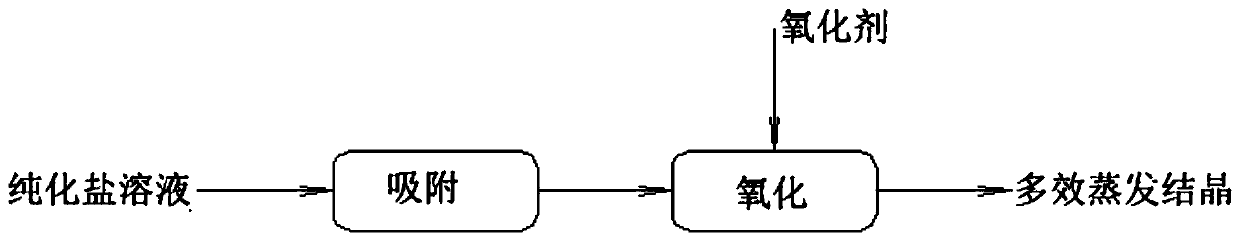

Method used

Image

Examples

Embodiment Construction

[0038] The following examples are provided for a better understanding of the present invention, and are not limited to the best embodiments, and do not limit the content and protection scope of the present invention. Any product identical or similar to the present invention obtained by combining with the features of other prior art shall fall within the protection scope of the present invention.

[0039]If the specific experimental steps or conditions are not indicated in the examples, it can be carried out according to the operations or conditions of the conventional experimental steps described in the literature in this field. The reagents or instruments used without the manufacturer's indication are all conventional reagent products that can be obtained from the market.

[0040] In order to illustrate the advantages of the method for recycling industrial waste salt in the present invention, the following specific methods for recycling industrial waste salt are provided. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com