Preparation method of micron superfine spherical sodium chloride

A sodium chloride, micron-scale technology, applied in the field of preparation of micron-scale ultrafine spherical sodium chloride for pore-making, can solve the problems of high equipment requirements, easy aggregation of ultrafine sodium chloride, high pH requirements, etc., to achieve sphericity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At room temperature, add 5.4g glycine to 100ml saturated sodium chloride solution, stir for half an hour, atomizer speed is 15000r / min, air inlet / outlet temperature is 150 / 80°C, collect sodium chloride crystals, and Dry in a vacuum oven at 80°C.

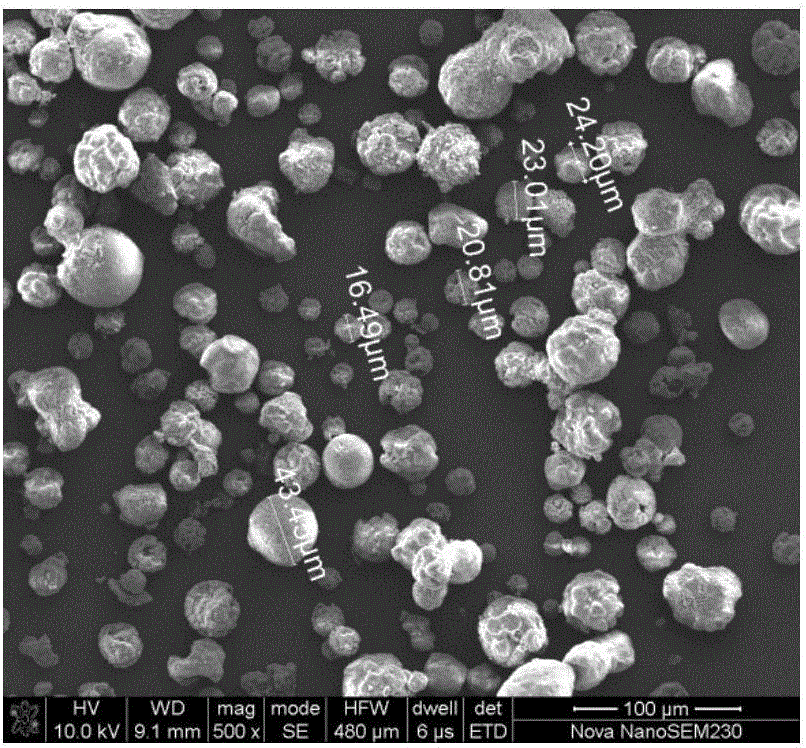

[0034] After spraying gold, scan the microscopic morphology of the prepared grains with a scanning electron microscope (SEM) and calculate the particle size, and the particle size distribution of sodium chloride is 15.31-44.45 μm (i.e. D 97 = 44.45 μm, D 10 =15.31 μm), and the primary crystallization yield was 61.2%. The sphericity is about 95%; the scan results are attached figure 1 .

Embodiment 2

[0036] At room temperature, add 5.4g glycine to 100ml saturated sodium chloride solution, stir for half an hour, atomizer speed is 20000r / min, air inlet / outlet temperature is 150 / 80°C, collect sodium chloride crystals, and Dry in a vacuum oven at 80°C.

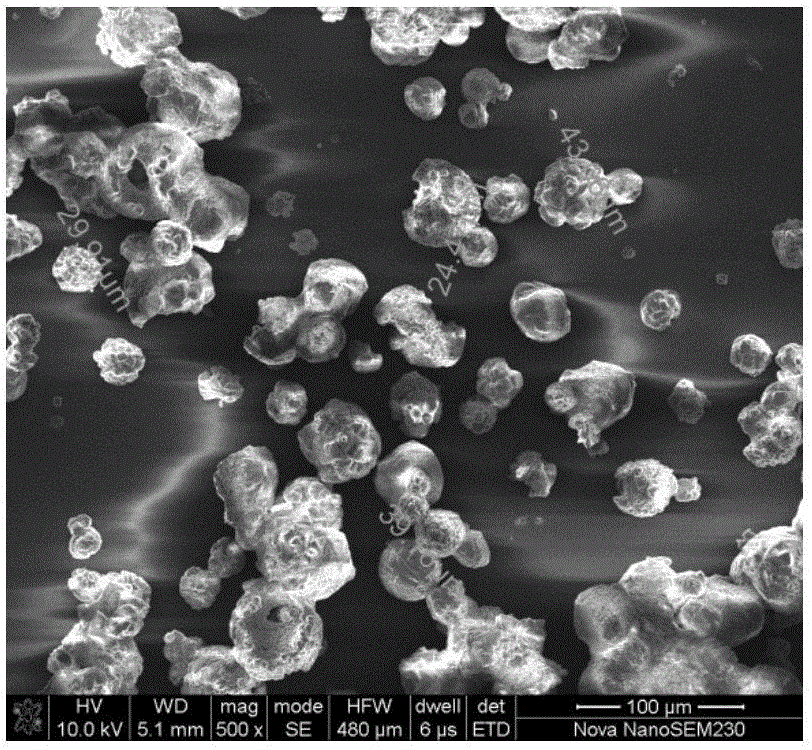

[0037] After spraying gold, scan the prepared crystal grain micro-morphology and calculate the particle size with a scanning electron microscope (SEM), and obtain a particle size distribution of sodium chloride of 13.42-43.66 μm (i.e. D 97 = 43.66 μm, D 10 =13.42 μm), and the primary crystallization yield was 57.3%. The sphericity is about 95%; the scan results are attached figure 2 .

Embodiment 3

[0039] At room temperature, add 5.4g glycine to 100ml saturated sodium chloride solution, stir for half an hour, atomizer speed is 25000r / min, air inlet / outlet temperature is 150 / 80°C, collect sodium chloride crystals, and Dry in a vacuum oven at 80°C.

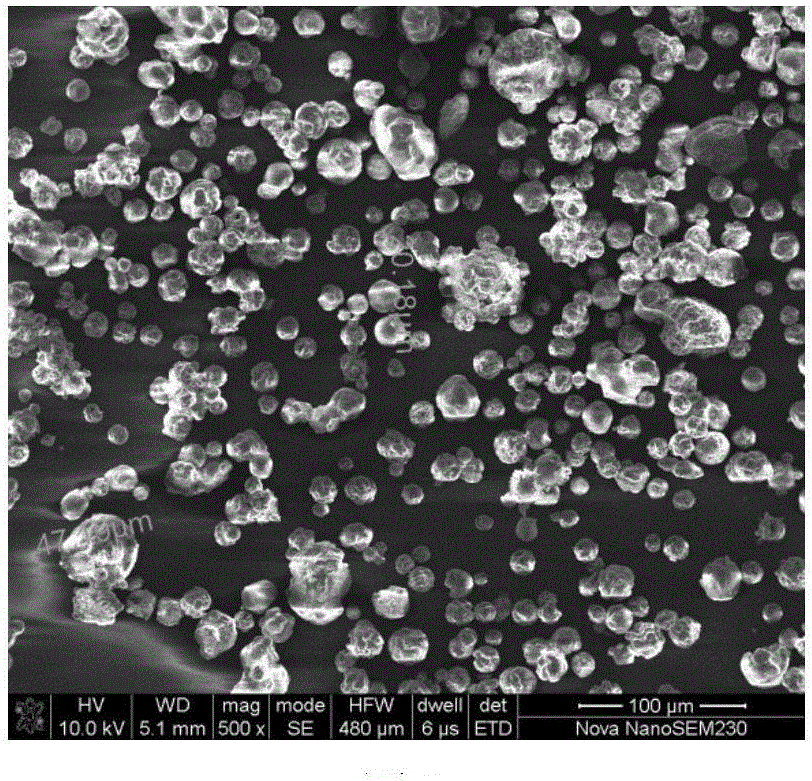

[0040] After spraying gold, scan the prepared crystal grain micro-morphology and calculate the particle size with a scanning electron microscope (SEM), and obtain a particle size distribution of sodium chloride of 10.18-41.19 μm (i.e. D 97 = 41.19 μm, D 10 =10.18 μm), the primary crystallization yield was 66.5%. The sphericity is greater than or equal to 99%; the scanning results are attached image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com