Waste fly ash washing water recycling treatment process and equipment

A garbage fly ash and processing technology, applied in heating water/sewage treatment, chemical industry, alkali metal halide shape preparation, etc., can solve problems such as high chloride ion content, affecting cement quality, cement kiln damage, etc., to achieve automation The effect of high degree, high degree of equipment automation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

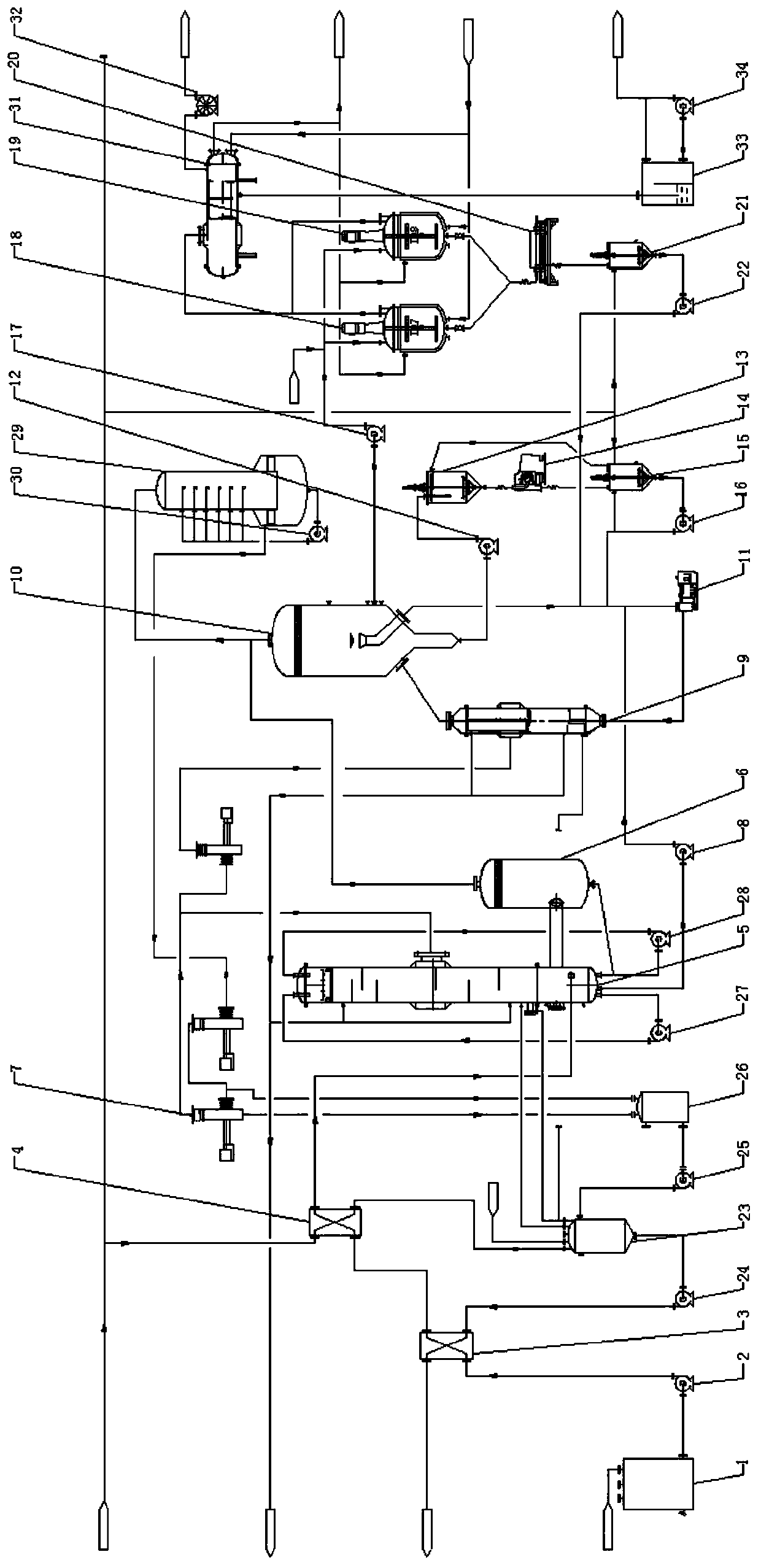

[0031] This embodiment provides a recycling process for waste fly ash washing water. The waste fly ash washing water contains sodium chloride and potassium chloride. Supersaturated sodium chloride is precipitated at high temperature, and the Supersaturated potassium chloride is precipitated, thereby realizing the separation of sodium chloride salt and potassium chloride salt in the garbage fly ash washing water, and obtaining industrial-grade sodium chloride salt and potassium chloride salt respectively, reducing the cost of solid waste or hazardous waste To achieve the purpose of resource recovery.

[0032] In this embodiment, the mass fraction of sodium chloride in the garbage fly ash washing water is 8.5%, the mass fraction of potassium chloride is 1.5%, and the flow rate is 20.0t / h. The waste fly ash washing water recycling process adopts such as figure 1 The shown equipment specifically includes the following steps:

[0033] S1. Garbage fly ash washing water is preheate...

experiment example

[0047] The conditions and operating parameters of using the equipment and process of the present invention to treat garbage fly ash washing water were tested, and the results are shown in Table 1.

[0048] Table 1

[0049] serial number

[0050] The above test results show that the waste fly ash washing water recycling process of the present invention has a high recovery rate of sodium chloride and potassium chloride, achieves the purpose of resource recovery and can meet the zero discharge requirement of waste water, and the energy consumption of the treatment process is low .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com