Process for efficiently producing fine-particle salt

A preparation process and fine particle technology, which are applied in the shape preparation of alkali metal halides, alkali metal chlorides, etc., can solve the problems of low utilization rate of edible salt processing, increase production and processing costs, loss of powder salt and waste, and save energy. The effect of equipment investment, reduction of processing steps, and simple production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

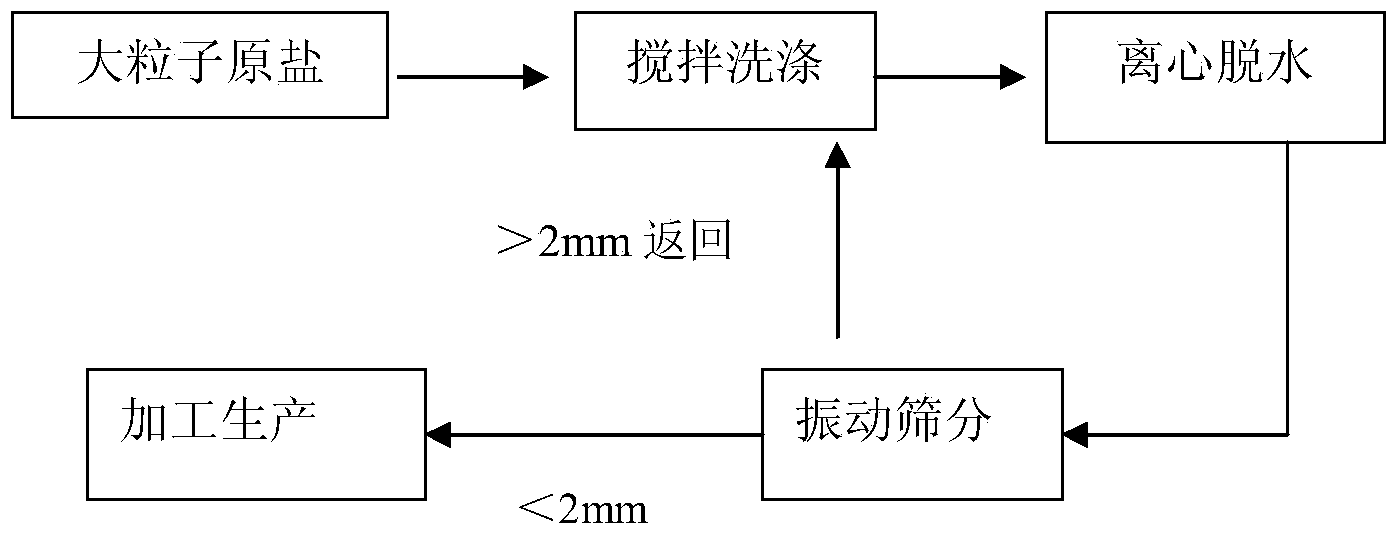

Method used

Image

Examples

Embodiment 1

[0017] ①Washing: Add large-grained raw salt with a particle size of 3mm in the salt washing tank for washing, and add saturated brine with a concentration of 24.5°Bé, and the solid-to-liquid ratio of raw salt to saturated brine is 6:4;

[0018] ② Centrifugation: The washed salt slurry in step ① is centrifuged and dehydrated by a centrifuge to obtain a centrifugal dehydration product, so that the water content of the centrifugal dehydration product is 5%;

[0019] ③Sieving: In the screening step ②, the centrifuged dehydration products with a particle size of 2.0mm are returned to the centrifugal salt slurry tank in step ② for further centrifugal sieving, so that the final screened out particle size <2.0 mm of fine grained salt.

Embodiment 2

[0021] ①Washing: Add raw material salt with a particle size of 9mm in the salt washing tank for washing, and add saturated brine with a concentration of 26°Bé, and the solid-to-liquid ratio of raw salt to saturated brine is 9:1;

[0022] ② Centrifugation: The washed salt slurry in step ① is centrifuged and dehydrated by a centrifuge to obtain a centrifugal dehydration product, so that the water content of the centrifugal dehydration product is 4%;

[0023] ③Sieving: In the screening step ②, the centrifuged dehydration products with a particle size of 2.0mm are returned to the centrifugal salt slurry tank in step ② for further centrifugal sieving, so that the final screened out particle size <2.0 mm of fine grained salt.

Embodiment 3

[0025] ①Washing: Add large-grained raw salt with a particle size of 15mm in the salt washing tank for washing, and add saturated brine with a concentration of 27°Bé, and the solid-to-liquid ratio of raw salt to saturated brine is 8:2;

[0026] ② Centrifugation: The washed salt slurry in step ① is centrifuged and dehydrated by a centrifuge to obtain a centrifuged dehydration product, so that the water content of the centrifuged dehydration product is 3%;

[0027] ③Sieving: In the screening step ②, the centrifuged dehydration products with a particle size of 2.0mm are returned to the centrifugal salt slurry tank in step ② for further centrifugal sieving, so that the final screened out particle size <2.0 mm of fine grained salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com