Fly ash washing cement kiln collaborative disposal and resource comprehensive utilization system and method

A technology of co-processing and cement kiln, applied in the field of fly ash treatment, can solve the problems of toxic chelating agents, hidden dangers, increase landfill land, etc., and achieve co-processing and comprehensive utilization of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

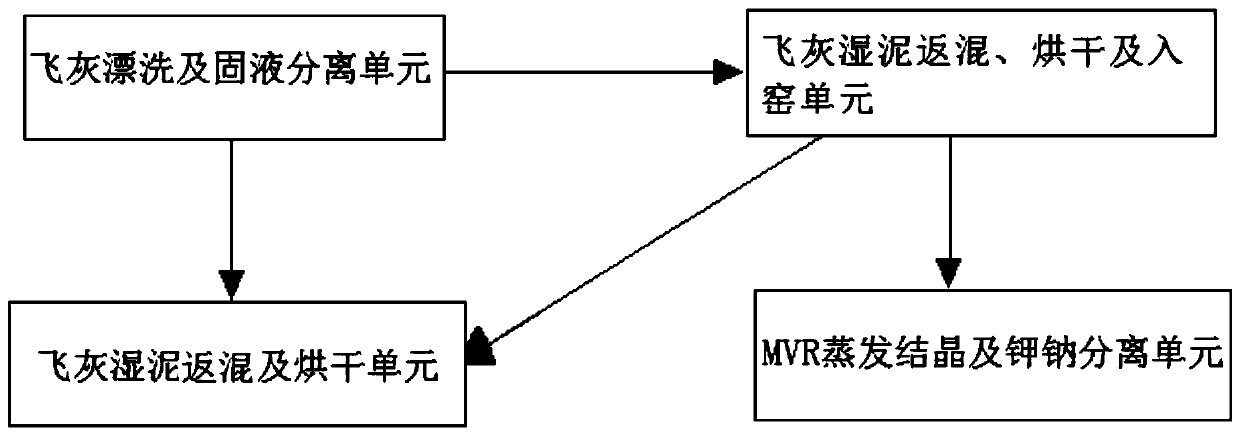

[0042] Such as figure 1 As shown, this embodiment is a co-processing and resource comprehensive utilization system for fly ash washing cement kiln, including fly ash rinsing and solid-liquid separation unit, fly ash wet mud back-mixing, drying and kiln entry unit, fly ash washing liquid Pretreatment unit and MVR evaporative crystallization and potassium and sodium separation unit, the fly ash rinsing and solid-liquid separation unit are respectively with the fly ash wet mud back-mixing, drying and kiln entering unit and fly ash washing liquid pretreatment unit connected, the fly ash washing solution pretreatment unit is respectively connected with the MVR evaporative crystallization and potassium and sodium separation unit and the fly ash wet mud back-mixing, drying and kiln entry unit.

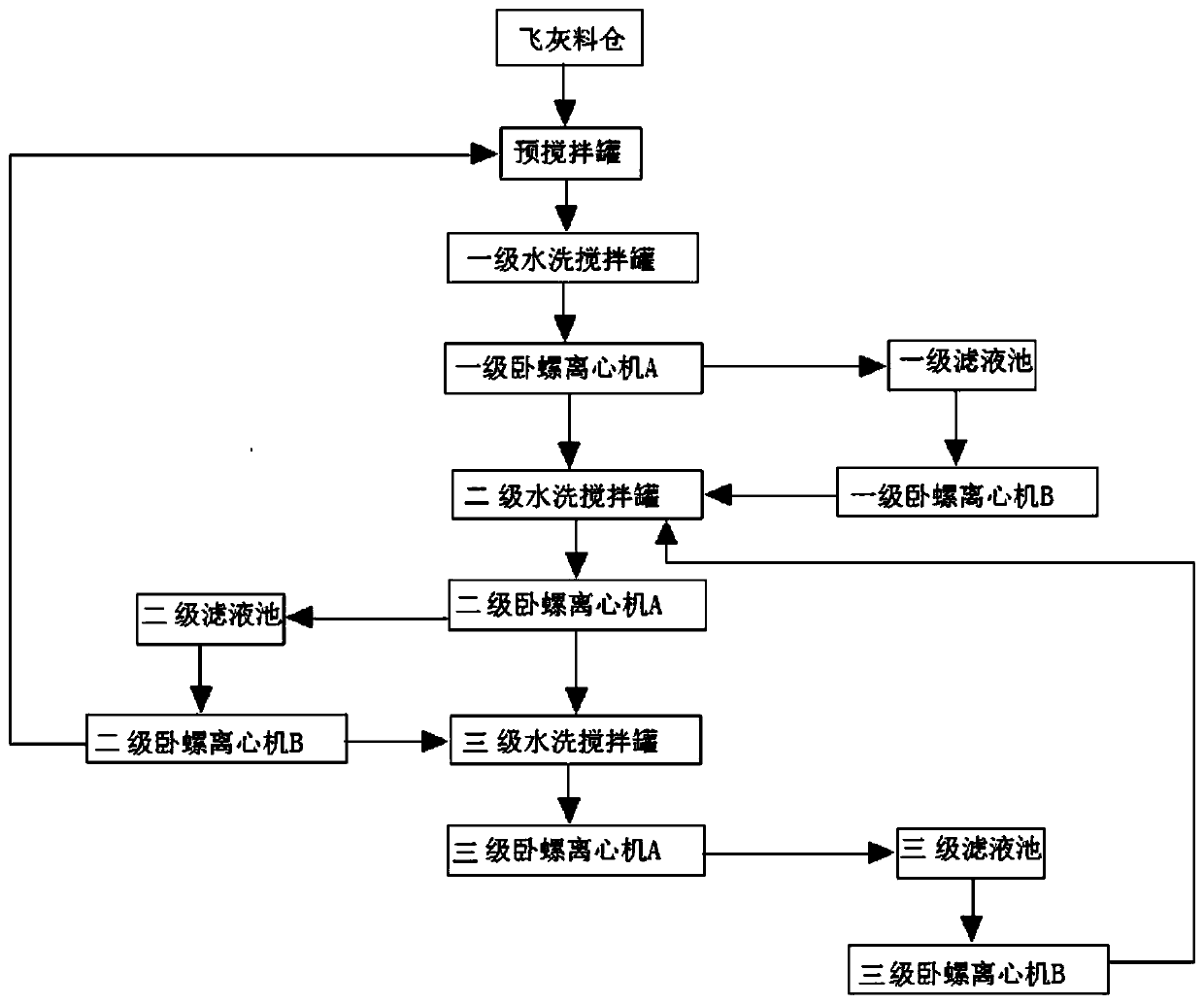

[0043] Such as figure 2 As shown, the fly ash rinsing and solid-liquid separation unit includes a fly ash silo, a pre-mixing tank, a primary washing mixing tank, a primary decanter centrifu...

Embodiment 2

[0052] A method for co-processing of fly ash and water-washed cement kiln and comprehensive utilization of resources in this embodiment, the method is carried out by using the system, and specifically includes the following steps:

[0053] (1) Separating fly ash from domestic waste incineration through fly ash rinsing and solid-liquid separation unit to obtain wet mud and fly ash washing liquid;

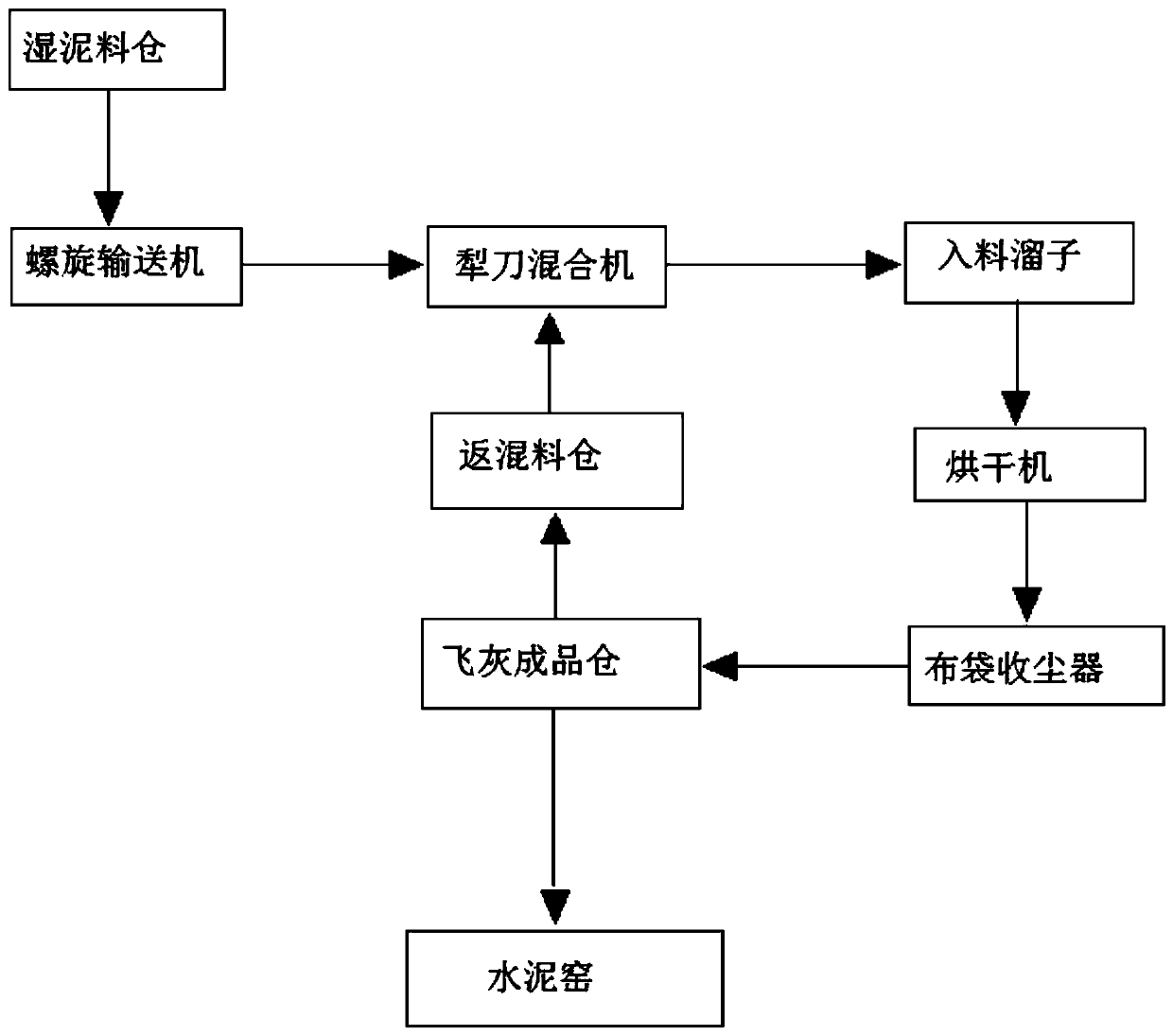

[0054] (2) After the wet mud is back-mixed with fly ash wet mud, dried and put into the kiln unit for treatment, fly ash powder and exhaust gas are obtained, and the fly ash powder is transported to the cement kiln for high-temperature calcination. The temperature is 400℃~600℃, the calcination time is 8~14s, the dioxin in the fly ash is decomposed, and the heavy metal ions are solidified in the cement clinker lattice;

[0055] (3) After the fly ash water washing liquid is processed by the fly ash water washing liquid pretreatment unit, wet mud and clear liquid are obtained, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com