Process for preparing high-quality industrial salt by utilizing garbage fly ash

A waste fly ash, high-quality technology, applied in the shape preparation of alkali metal halides, alkali metal chlorides, alkali metal halide purification, etc., can solve the problems of difficult separation of potassium and sodium, and heavy metals are easy to exceed the standard, so as to reduce production costs , Reduce the number of washing stages and reduce equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

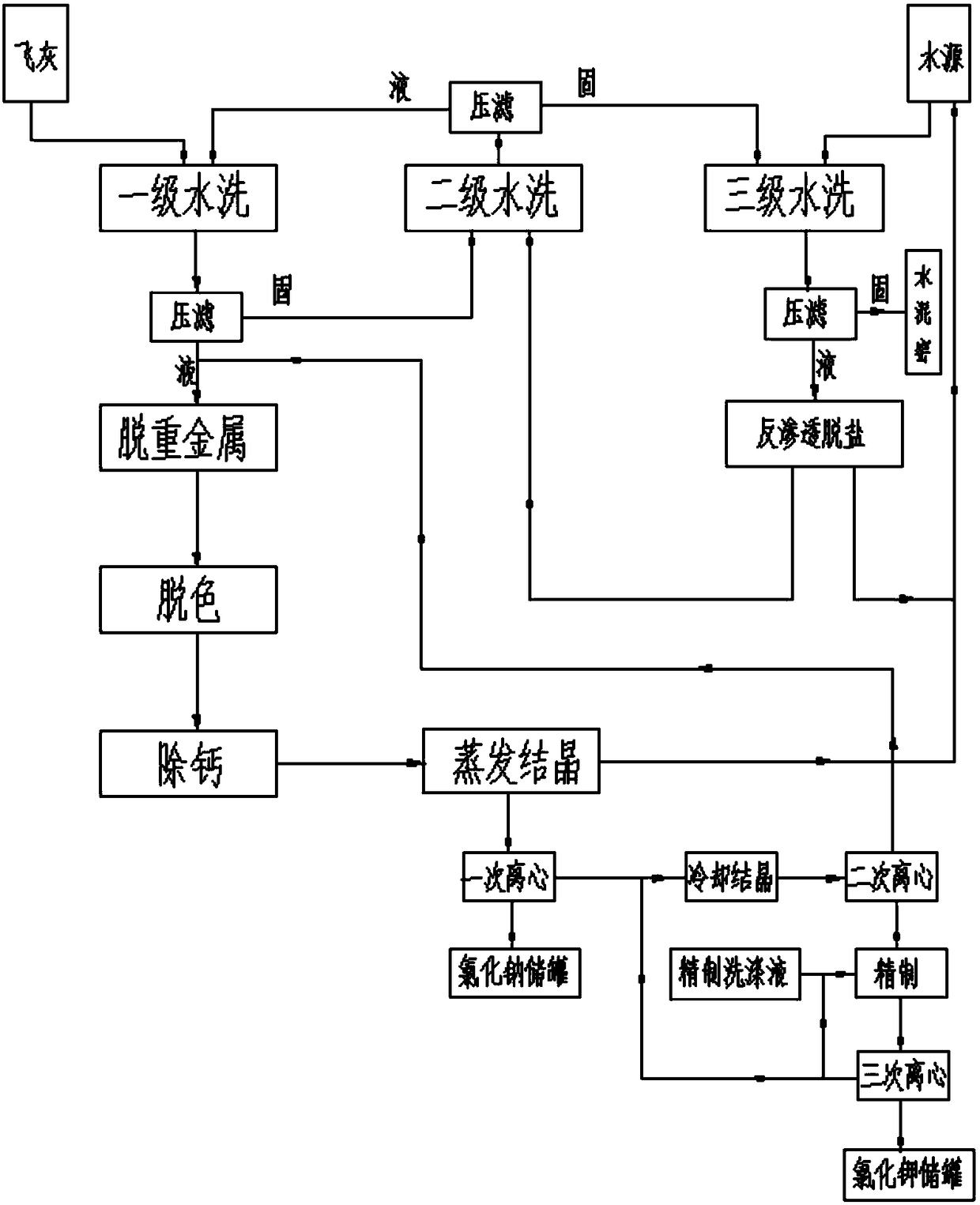

[0040] A process for preparing high-quality industrial salt from garbage fly ash ( figure 1 ), including the steps of washing fly ash, removing heavy metals, decolorizing, decalcifying, evaporative crystallization and separating potassium and sodium, as follows:

[0041] The washing of the fly ash is a three-level countercurrent washing, including the first level of water washing, the second level of water washing and the third level of water washing;

[0042] After the first stage of water washing, solid-liquid separation is carried out. After the solid is crushed, it enters the second stage of water washing, and the liquid enters the step of removing heavy metals. The mass ratio of fly ash to water in the first stage of water washing is 1:1;

[0043] After the second stage of washing, solid-liquid separation is carried out, and the solid is crushed and then enters the third stage of water washing, and the liquid is used as the water source of the first stage of water washing...

Embodiment 2

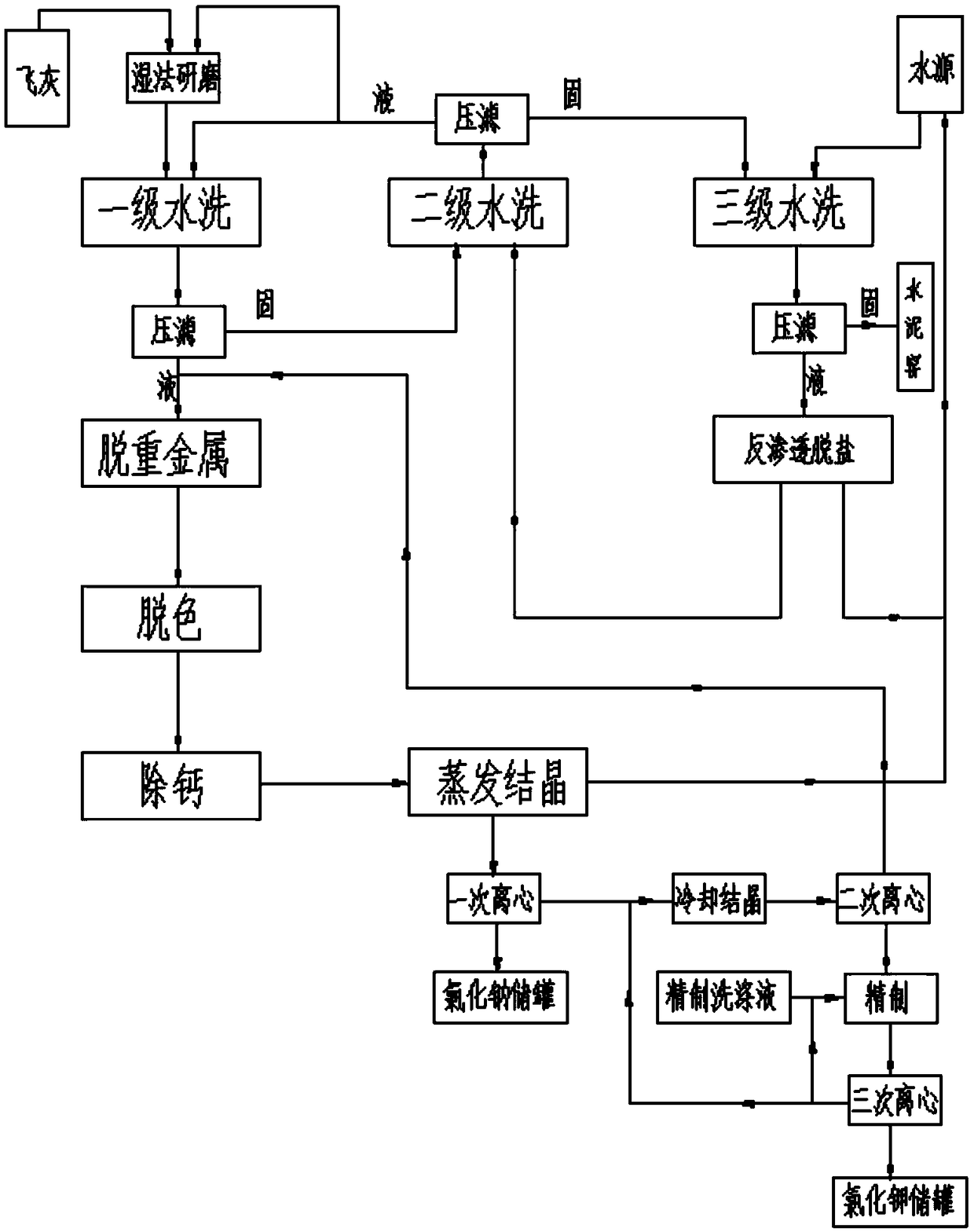

[0047] A process for preparing high-quality industrial salt from garbage fly ash ( figure 2 ), including the steps of washing fly ash, removing heavy metals, decolorizing, decalcifying, evaporative crystallization and separating potassium and sodium, as follows:

[0048] Before the fly ash washing step, the fly ash is wet-grinded, and the slurry formed after the wet grinding enters the fly ash washing step;

[0049] The washing of the fly ash is a three-level countercurrent washing, including the first level of water washing, the second level of water washing and the third level of water washing;

[0050] After the first stage of water washing, solid-liquid separation is carried out. After the solid is crushed, it enters the second stage of water washing, and the liquid enters the heavy metal removal step. The water consumption of the first stage of water washing + the water consumption of fly ash wet grinding and the mass ratio of fly ash = 1 :1, that is, the mass ratio of ...

Embodiment 3

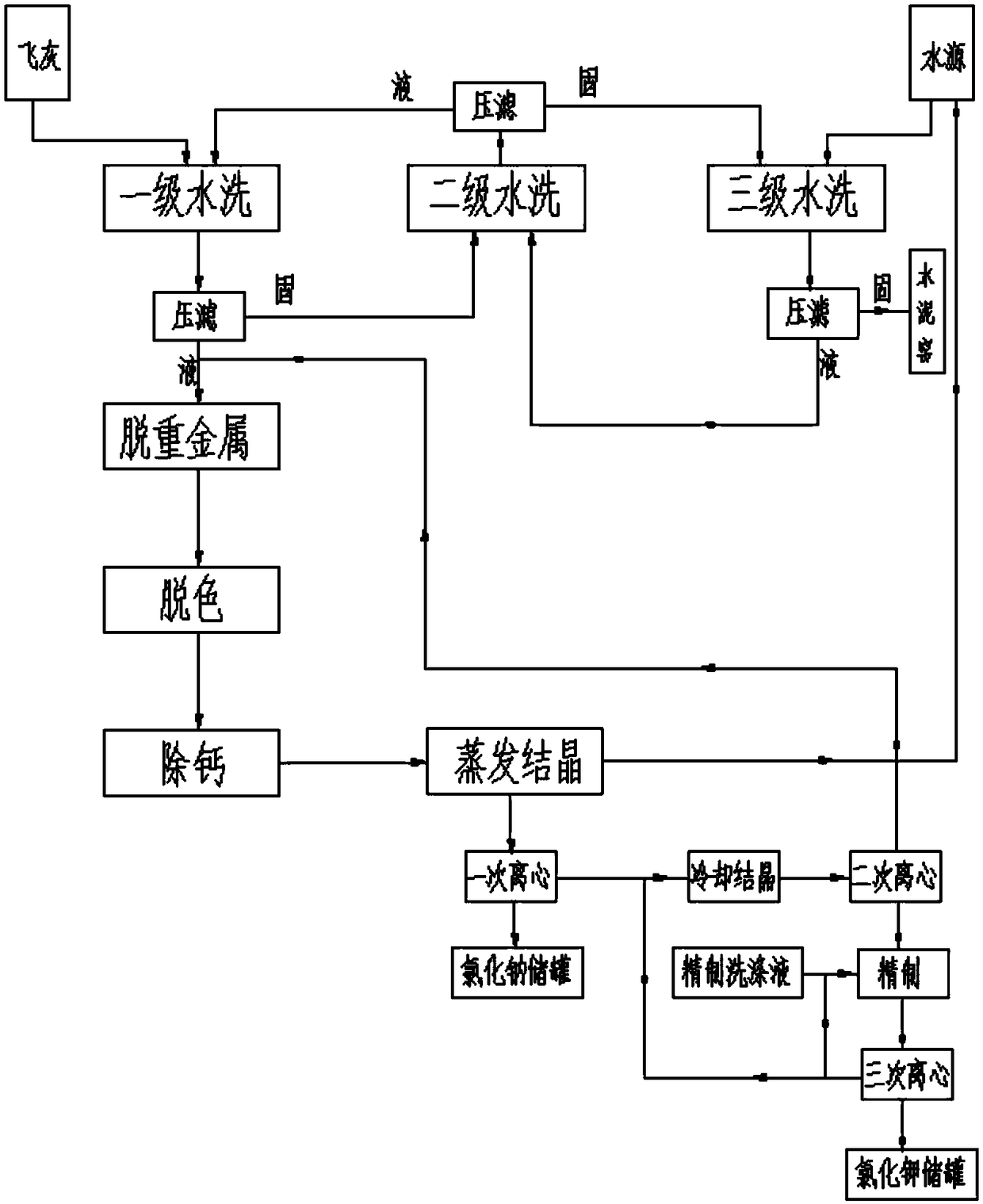

[0055] A process for preparing high-quality industrial salt from garbage fly ash ( image 3 ), including the steps of washing fly ash, removing heavy metals, decolorizing, decalcifying, evaporative crystallization and separating potassium and sodium, as follows:

[0056] The washing of the fly ash is a three-level countercurrent washing, including the first level of water washing, the second level of water washing and the third level of water washing;

[0057] After the first stage of water washing, solid-liquid separation is carried out. After the solid is crushed, it enters the second stage of water washing, and the liquid enters the step of removing heavy metals. The water consumption of the first stage of water washing and the mass ratio of fly ash = 1:1;

[0058] After the second stage of washing, solid-liquid separation is carried out. The mass ratio of fly ash to water in the second stage of water washing is 1: 1. After the solid is crushed, it enters the third stage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com