Brominated styrene/butadiene copolymer fire retardant and bromination method thereof

A technology for brominating styrene and butadiene, applied in the field of brominated copolymer flame retardants and their bromination, can solve the problems of hydrogen bromide vapor hazards, toxic and harmful fumes, etc. The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

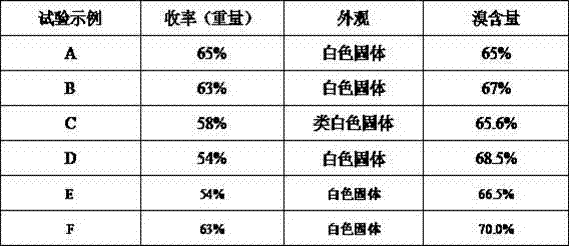

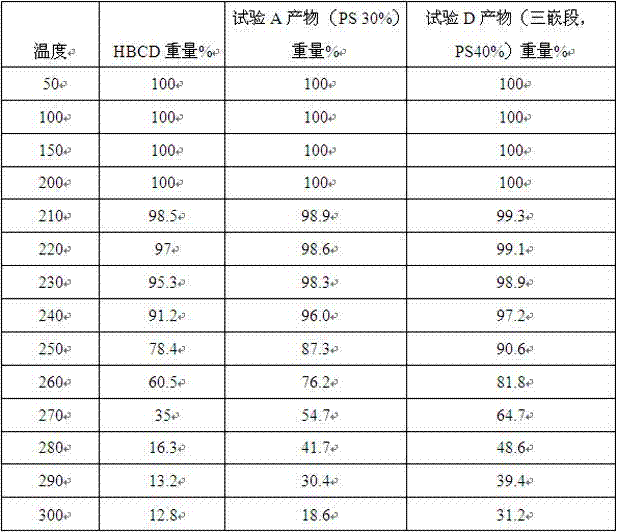

Examples

Embodiment A

[0023] Add 20g of SBS (D1101, 30% styrene content) and 200g of isobutanol, 12g of sodium bromide and 50g of water into a 250mL chlorination reactor equipped with a condenser. into a dilute alkali solution, the temperature of the reaction solution was gradually raised to 45°C, then 2g of ferric chloride was added, the temperature was raised to 80°C and stirred for 1 hour. The temperature was purged with nitrogen, filtered and washed to obtain 28 g of the target product as a white solid, namely brominated styrene / butadiene copolymer (abbreviated as Br-SBS).

Embodiment B

[0025] Add 20g of SBS (MD6459, 75% styrene content) and 200g of isobutanol, 6g of sodium bromide into a 250mL chlorination reactor equipped with a condenser, and then inject chlorine gas from the bottom of the reactor after heating and dissolving , the tail gas is passed into the dilute alkali solution, after three hours, 2g of ferric chloride is added and the temperature is raised to 80°C, stirred for one hour, after the reaction is completed, the temperature is purged with nitrogen to cool down, the reaction liquid is filtered in a closed filter, and the obtained light yellow solid Pour it into 100mL of methanol and heat up to 60°C for recrystallization. After filtering and washing with water, a white solid was obtained, which was Br-SBS.

Embodiment C

[0027] Bromination reaction of tri-block SBS, synthesis of SBS: The synthesis of SBS adopts three-step feeding method. Firstly, 100g of 30% styrene-cyclohexane solution is added to the polymerization bottle, and after impurities are removed by chemical purification, 0.3g is added. Initiate polymerization with n-butyllithium to obtain the active polymer solution of polystyrene in the first stage, add 100g of 30% butadiene-cyclohexane solution and tetrahydrofuran corresponding to the required 1,2-structure content in another polymerization bottle After the residual impurities are removed by chemical purification, the first stage of active polystyrene solution that has been polymerized is immediately pressed with high-purity nitrogen, and the active polystyrene gradually triggers the second stage of butadiene monomer to continue to grow; the second stage After the stage of polymerization is completed, the third stage of styrene-cyclohexane solution that has been purified by chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com