Catalyst for producing low-carbon mixed alcohol by using synthesis gas as well as preparation method and application of catalyst

A low-carbon mixed alcohol and catalyst technology, applied in the field of catalysis, can solve the problem of low selectivity of isobutanol and achieve the effects of low raw material cost, low reaction pressure and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

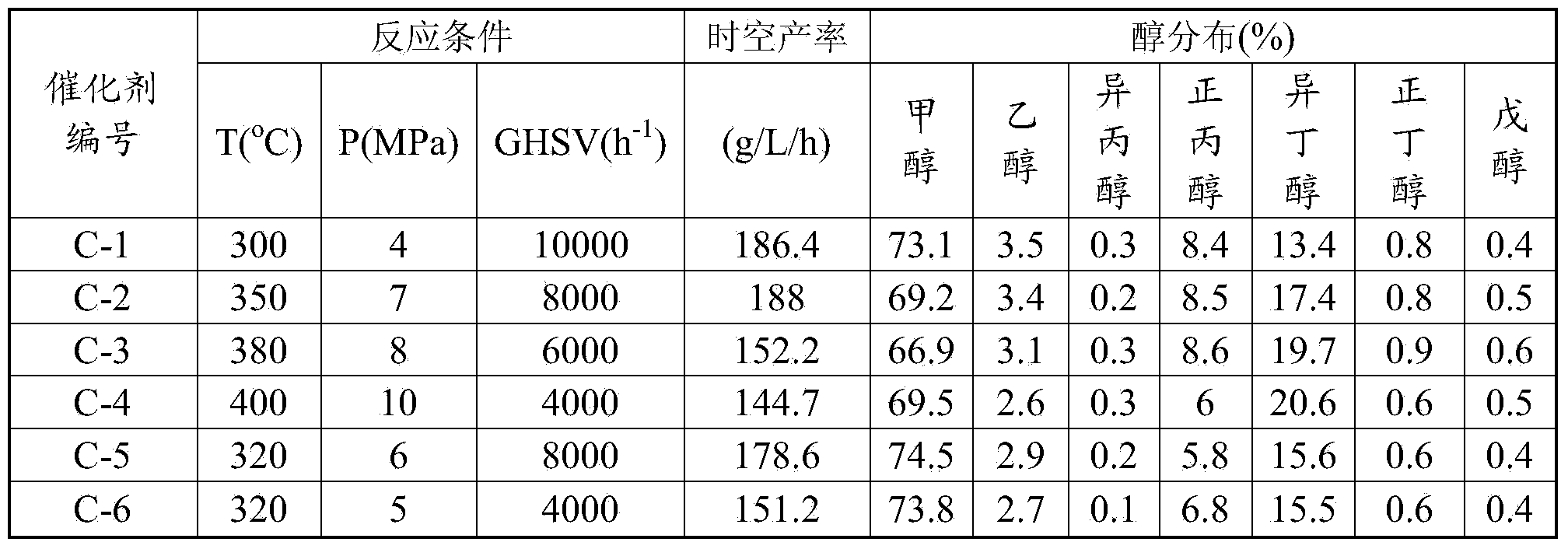

Examples

Embodiment 1

[0032]Weigh 7.95gCu(NO 3 ) 2 ·3H 2 O, 8.84gZn(NO 3 ) 2 ·6H 2 O, 3.56gZr(NO 3 ) 4 ·5H 2 O, 1.56gFe(NO 3 ) 3 9H 2 O, while adding 0.82gMn(NO 3 ) 2 Prepare 80ml solution, add the solution dropwise to ammonia water at 60°C, control the pH of the titration end point to 8.0, continue to stir for 20 minutes after the titration is completed, then age at 70°C for 30 minutes, then wash and filter repeatedly with deionized water 5 times, after drying at 120°C for 12 hours, the catalyst was ground into powder and impregnated in 6% CsNO 3 In the solution for 12 hours, after impregnation, dry again at 120°C for 12 hours, and finally bake at 300°C for 6 hours, press into tablets, and crush the catalyst to 20-40 mesh. The catalyst is marked as C-1.

Embodiment 2

[0034] Weigh 5.48gCu(NO 3 ) 2 ·3H 2 O, 9.23gZn(NO 3 ) 2 ·6H 2 O, 1.95gZr(NO 3 ) 4 ·5H 2 O, while adding 1.59gCe(NO 3 ) 3 ·6H 2 O to make a 70ml solution, add the solution dropwise to the sodium carbonate solution at 50°C, control the pH of the titration end point to 7.5, continue stirring for 20min after the titration is completed, then age at 60°C for 30min, and then use deionized water Repeatedly washing and filtering 5 times, drying at 120°C for 12 hours, grinding the catalyst into powder and impregnating it in 8% K 2 CO 3 In the solution for 12 hours, after impregnation, dry again at 120°C for 12 hours, and finally bake at 350°C for 6 hours, press into tablets, and crush the catalyst to 20-40 mesh. The catalyst is marked as C-2.

Embodiment 3

[0036] Weigh 6.85gCu(NO 3 ) 2 ·3H 2 O, 5.72gZn(NO 3 ) 2 ·6H 2 O, 5.64gZr(NO 3 ) 4 ·5H 2 O, 0.23gMn(NO 3 ) 2 , while adding 0.53gCe(NO 3 ) 3 ·6H 2 O was made into a 75ml solution, and the solution was added dropwise to the sodium carbonate solution at 85°C, and the pH at the end point of the titration was controlled to be 7.0. After the titration was completed, continue to stir for 20 minutes, then aged at 90°C for 30 minutes, and then deionized water Repeated washing and filtering 5 times, drying at 120°C for 12 hours, grinding the catalyst into powder and impregnating it in 8% RbNO 3 In the solution for 12 hours, after impregnation, dry again at 120°C for 12 hours, and finally bake at 450°C for 6 hours, press into tablets, and crush the catalyst to 20-40 mesh. The catalyst is marked as C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com