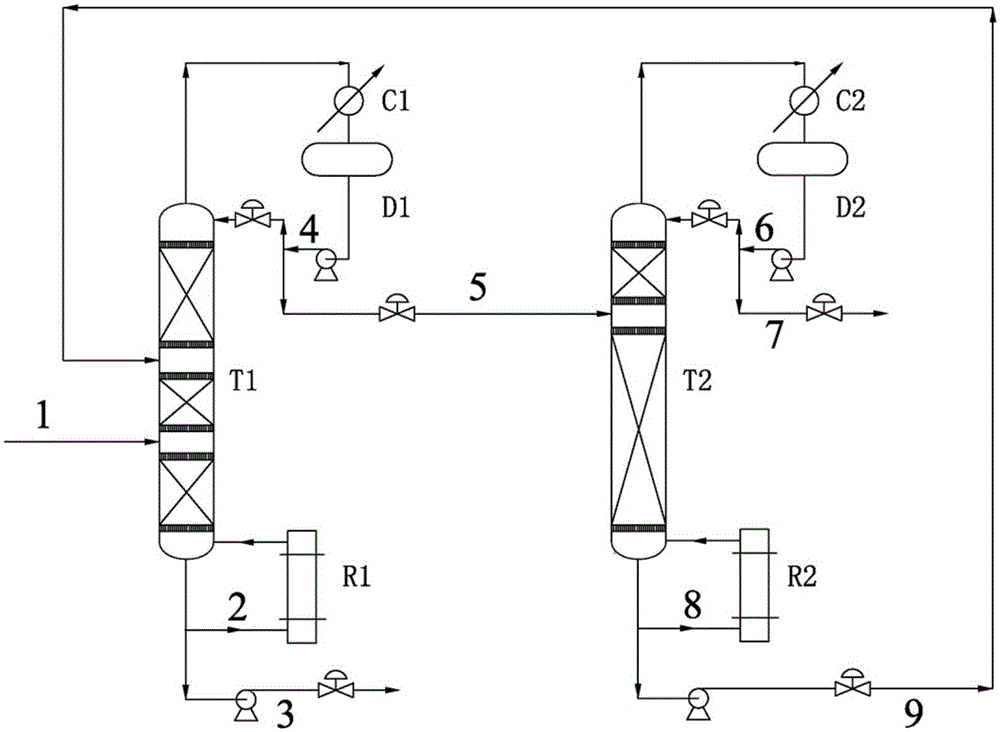

Method for separating isobutyl alcohol and normal heptanes azeotropic system by using pressure swing distillation

A technology of pressure swing rectification and n-heptane, which is applied in the direction of distillation purification/separation, chemical instruments and methods, and preparation of organic compounds, etc., to achieve the effects of high heat utilization rate, low equipment investment cost, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The feed temperature is 25° C., the flow rate is 1000 kg / h, and the pressure is 1 atm (absolute pressure). The feed contains 80% isobutanol and 20% n-heptane. The theoretical plate number of the atmospheric column is 28, the inner diameter of the tower is 0.503m, the feed plate of the fresh stream is 11, and the feed plate of the circulating stream is 18; the theoretical plate number of the pressurized tower is 18, the inner diameter of the tower is 0.653m, and the feed plate is 15. The operating pressure of the atmospheric column is 1atm (absolute pressure), the reflux ratio is 1.2, the temperature at the top of the tower is 91.0°C, and the temperature at the bottom of the tower is 112.3°C; the operating pressure of the pressurized tower is 12atm (absolute pressure), the reflux ratio is 1.7, and the tower top The temperature is 212.6°C, and the bottom temperature is 232.8°C. The isobutanol product obtained after separation has a purity of 99.90% and a yield of 99.90%,...

Embodiment 2

[0049] The feed temperature is 25° C., the flow rate is 1000 kg / h, and the pressure is 1 atm (absolute pressure). The feed contains 80% isobutanol and 20% n-heptane. The theoretical plate number of the atmospheric column is 28, the inner diameter of the tower is 0.518m, the feed plate of the fresh stream is 13, and the feed plate of the circulating stream is 15; the theoretical plate number of the pressurized tower is 18, the inner diameter of the tower is 0.649m, and the feed plate is 13. The operating pressure of the atmospheric column is 1atm (absolute pressure), the reflux ratio is 1.4, the temperature at the top of the tower is 91.0°C, and the temperature at the bottom of the tower is 112.2°C; the operating pressure of the pressurized tower is 12atm (absolute pressure), and the reflux ratio is 1.5. The temperature was 212.7°C, and the bottom temperature was 232.8°C. The purity of the isobutanol product obtained after separation is 99.89%, and the yield is 99.89%, and the...

Embodiment 3

[0051] The feed temperature is 25° C., the flow rate is 1000 kg / h, and the pressure is 1 atm (absolute pressure). The feed contains 75% isobutanol and 25% n-heptane. The theoretical plate number of the atmospheric column is 28, the inner diameter of the tower is 0.561m, the feed plate of the fresh stream is 15, and the feed plate of the circulating stream is 17; the theoretical plate number of the pressurized tower is 18, the inner diameter of the tower is 0.758m, and the feed plate is 14. The operating pressure of the atmospheric column is 1atm (absolute pressure), the reflux ratio is 1.7, the temperature at the top of the tower is 91.0°C, and the temperature at the bottom of the tower is 112.2°C; the operating pressure of the pressurized tower is 13atm (absolute pressure), the reflux ratio is 2.2, and the tower top The temperature is 217.6°C, and the bottom temperature is 242.5°C. The purity of the isobutanol product obtained after separation is 99.80%, and the yield is 99....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com