Device and method for maintaining liquid level balance of alkaline electrolysis system and inhibiting blow-by risk

An electrolysis system and liquid level balance technology, applied in the direction of electrolysis process, electrolysis components, energy input, etc., can solve the problems of gas crossover risk, liquid level balance breaking, etc., to achieve the suppression of cross gas risk, good liquid level balance, and reduce liquid The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

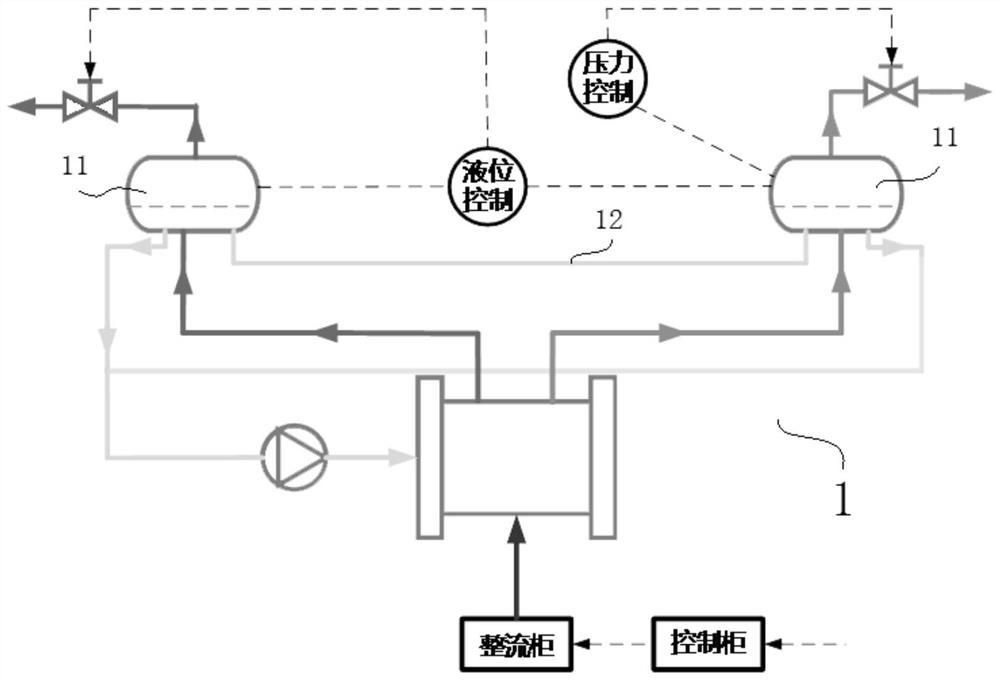

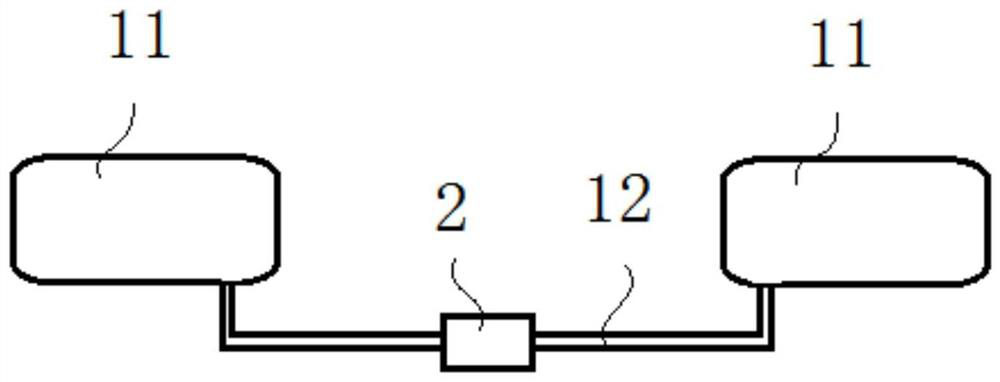

[0035] A method for suppressing the risk of cross-gas in an alkaline electrolysis system includes installing a safety device for suppressing the risk of cross-gas on the U-shaped pipe 12 between two gas-liquid separators 11 in the alkaline electrolysis system 1 .

[0036] In the present invention, by installing a safety device on the U-shaped tube to suppress the risk of cross-gas, it can effectively prevent the lye in the gas-liquid separator on one side from flowing into the other side under the action of pressure with hydrogen or oxygen when the electrolysis power changes. , and then avoid the risk of cross-gas caused by the liquid level balance being broken, solve the safety problem of fluctuating renewable energy off-grid hydrogen production, and improve the safety performance of the off-grid hydrogen production of the alkaline electrolysis system.

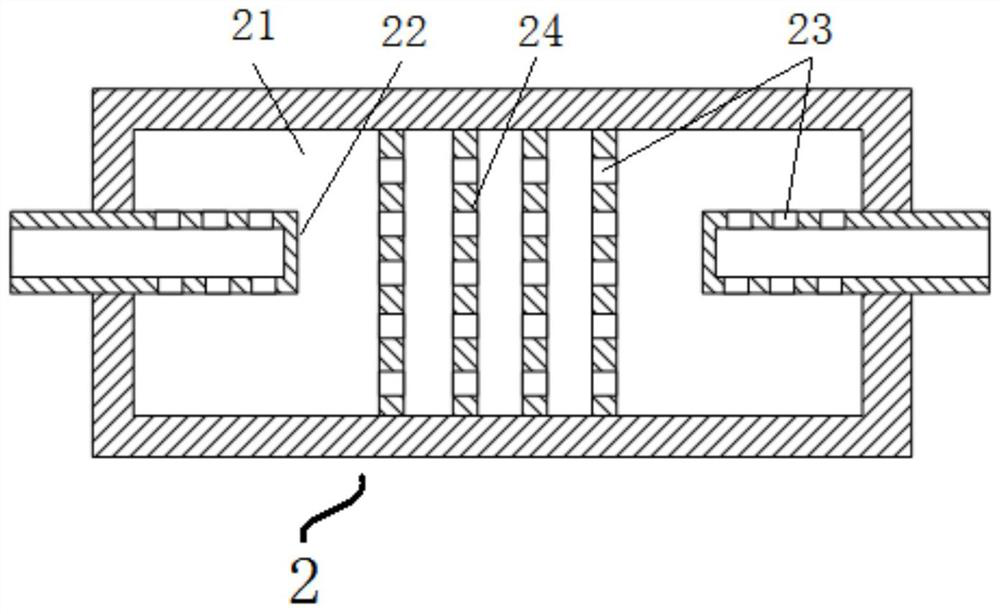

[0037] In the present invention, there are many ways to achieve the above-mentioned suppression of the risk of cross-gas, as...

Embodiment 2

[0047] A device for maintaining the liquid level balance of the alkaline electrolysis system and suppressing the risk of cross-gas, the structure of which is the same as that of the current limiting device described in the above-mentioned embodiment 1.

Embodiment 3

[0049] An alkaline electrolysis system that maintains liquid level balance and suppresses the risk of cross-gas, including a device for maintaining the liquid level balance of the alkaline electrolysis system and suppressing the risk of cross-gas in Embodiment 2, and the device is preferably installed in a U-shaped pipe 12 in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com