Biomass thermal cracking water-cooling carbon-gas co-production gasification system

A technology of biomass pyrolysis and gas purification system, which is applied in the direction of gasification process, gasification device feeding tool, and manufacture of combustible gas, etc. It can solve the problems of low purification efficiency, low purity of biomass gas, and insufficient combustion efficiency. Achieve the effects of reducing gasification energy consumption, increasing raw material bulk density, increasing gas production and gas production uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the description of the drawings.

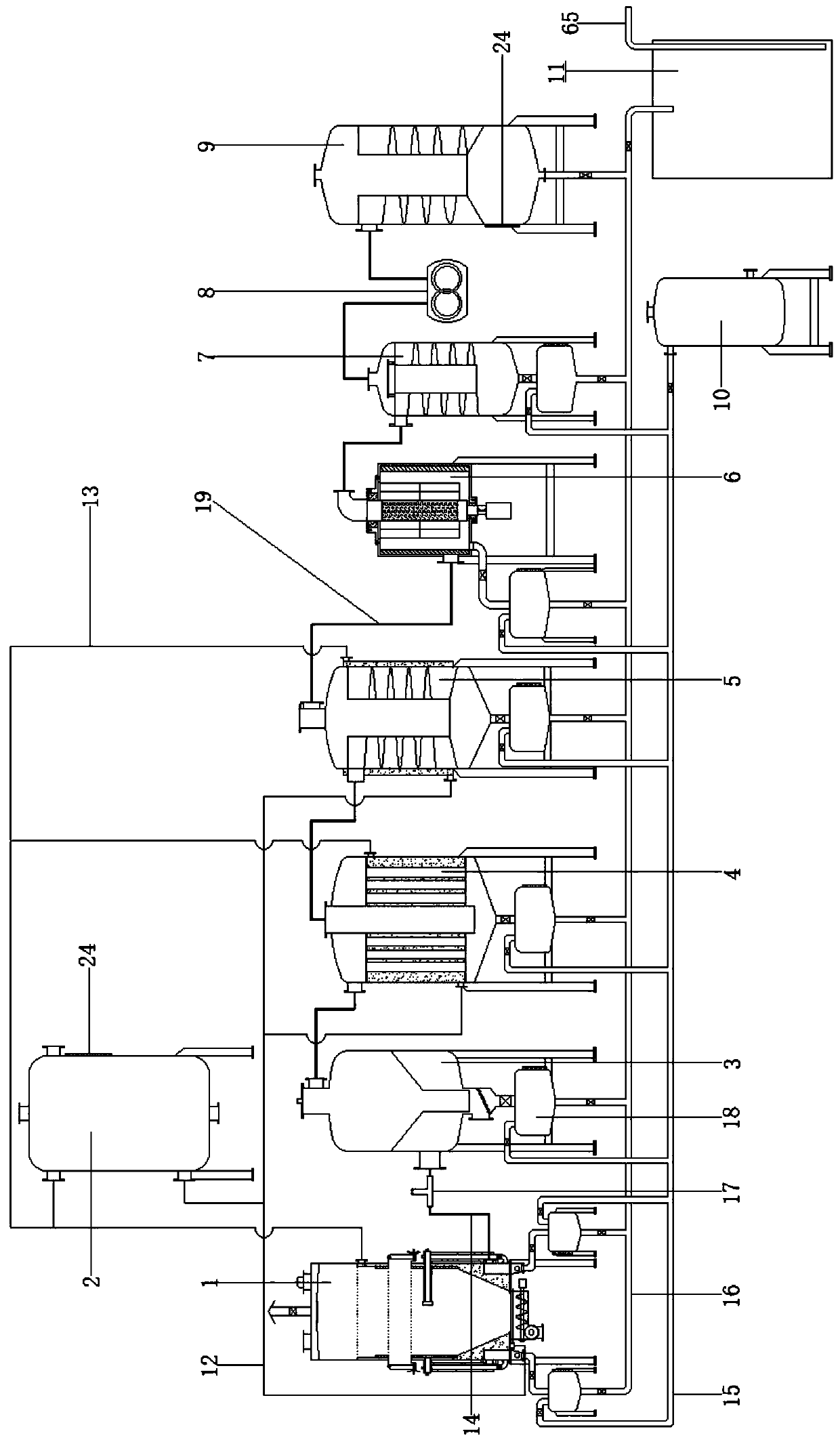

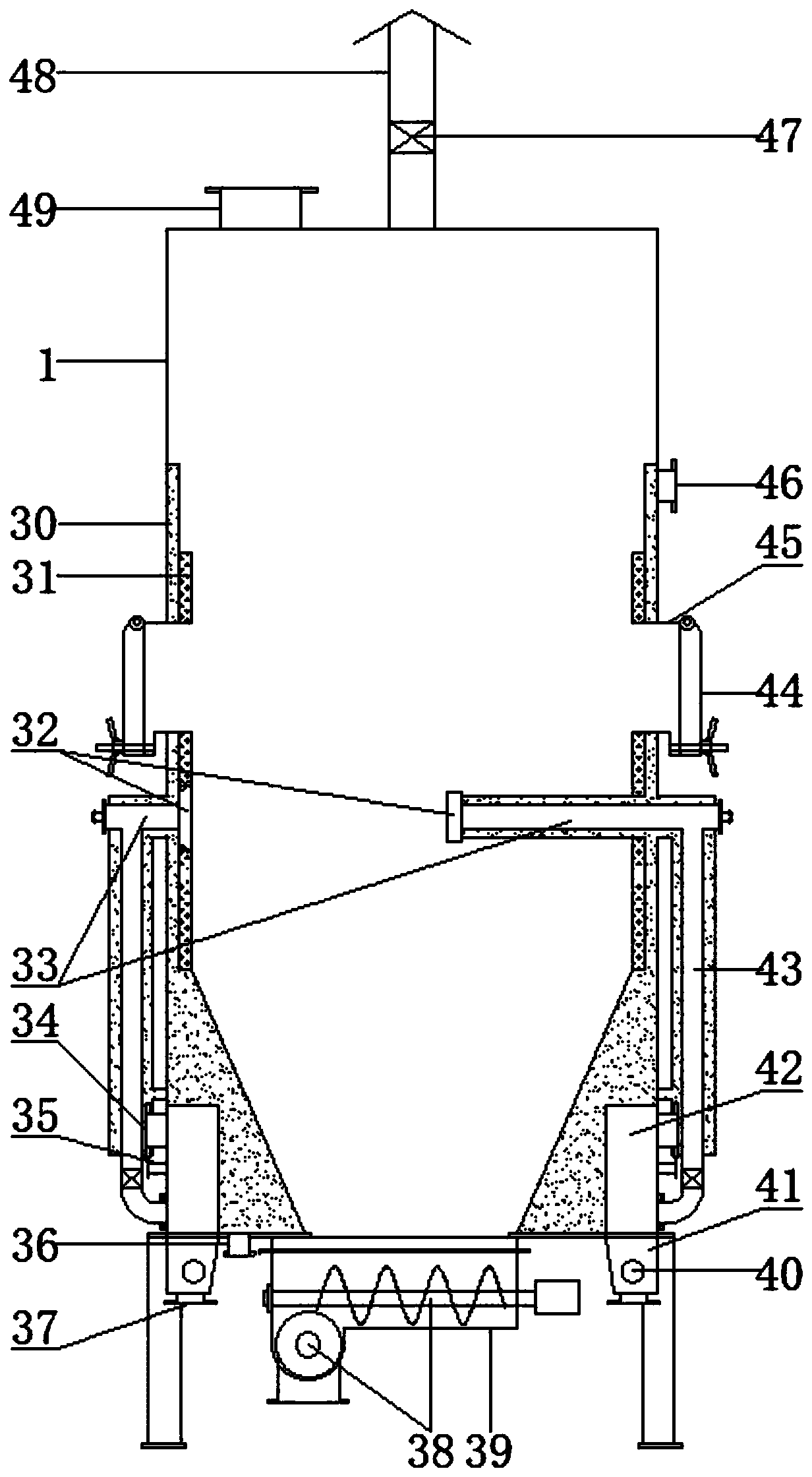

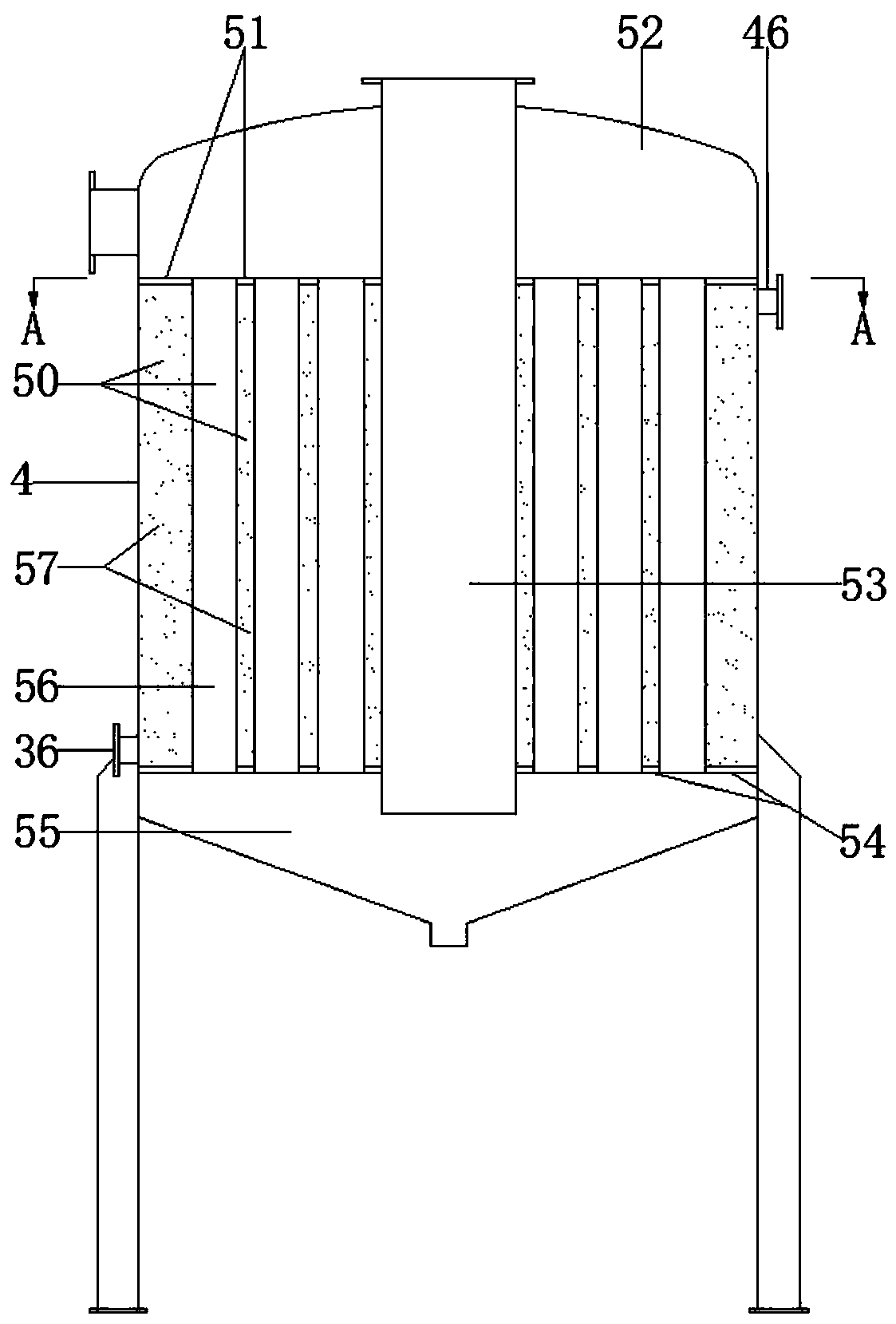

[0034] Such as figure 1 , 2 ,3,4,5,6,7,8, a biomass pyrolysis water-cooled carbon-gas co-production gasification system, including a gasifier 1, a cooling water tank 2, and several groups of gas purification systems, gas purification systems Including the sand filter tank 3, the cooling tank 4, the filter 5, the centrifugal separator 6, the Roots blower 8 and the gas storage tank 9 which are connected in series by the gas pipe B19. The gas outlet 34 of the gasifier 1 is connected with the gas pipe A14 The air inlet of the sand filter tank 3 is connected, the gas pipe A14 is provided with a gas exchange valve 17; the gasifier 1 is provided with a cooling water jacket A30, the outer wall of the filter 5 is provided with a cooling water jacket B64, and the cooling tank 4 is provided with Cooling zone 50, cooling water jacket A30, cooling water jacket B64, cooling zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com