Microbial fuel cell three-level continuous type waste water nitrogen-removing treatment method and device

A fuel cell and wastewater treatment technology, applied in biochemical fuel cells, biological water/sewage treatment, fuel cells, etc., can solve the problems of few microorganisms, complex species, unclear substrate pathways, etc., and achieve good treatment effect and treatment time. The effect of large and shortened start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of novel anode

[0033] a. Production and pretreatment of anode plates: take a piece of square carbon fiber felt with a specification of 16×16cm and a thickness of 0.5cm, and take 16 pieces of strip-shaped carbon fiber felt with a specification of 16cm×1.0cm and a thickness of 0.5cm. Each of the 8 strip-shaped carbon fiber felts has a spacing of 1 cm, and is symmetrically fixed on both sides of the square carbon fiber felt to form a carbon fiber felt pole plate, and the carbon fiber felt pole plate is put into deionized water and boiled for 30 minutes. , and the carbon fiber felt anode plate prepared by natural cooling was stored in a refrigerator at 4°C for later use;

[0034] b. Preparation of Pseudomonas putida culture solution: Pseudomonas putida, the bacterial strain numbered as CGMCC NO: 1.1003 preserved on the slant, was inoculated into 50 mL of seed culture medium, and each of the seed culture medium was The dosage of components ar...

Embodiment 2

[0036] Embodiment 2: the preparation of novel anode

[0037] A. the making of anode plate and pretreatment are basically the same as embodiment 1, and difference is that the thickness of square carbon fiber felt is 0.8cm;

[0038] B. the preparation of Pseudomonas putida nutrient solution is identical with embodiment 1;

[0039] c. Immobilization of Pseudomonas putida: take the Pseudomonas putida culture solution obtained in b. step for subsequent use, take the carbon fiber felt anode plate obtained in a. step for subsequent use, and mix 10g of polyvinyl alcohol and 0.6g of alginic acid Add sodium to 100mL of distilled water, heat it in a boiling water bath to dissolve it, stir it evenly with a glass rod, cool to room temperature, mix it with 1.2g activated carbon powder, add 10mL of Pseudomonas putida culture solution, and mix it evenly , and then evenly spread the mixed solution on the carbon felt anode, and finally put the anode plate into the saturated boric acid solution...

Embodiment 3

[0040] Embodiment 3: the preparation of novel anode

[0041] A. the making of anode plate and pretreatment are basically the same as embodiment 1, the difference is that the thickness of the square carbon fiber felt is 1.0cm;

[0042] B. the preparation of Pseudomonas putida nutrient solution is identical with embodiment 1;

[0043] c. Immobilization of Pseudomonas putida: take the Pseudomonas putida culture solution obtained in step b. for subsequent use, and take the carbon fiber felt anode plate obtained in step a. for subsequent use, and mix 11g of polyvinyl alcohol and 0.7g of alginic acid Add sodium to 120mL of distilled water, heat it in a boiling water bath to dissolve it, stir it evenly with a glass rod, cool to room temperature, mix it with 1.3g of activated carbon powder, add 12mL of Pseudomonas putida culture solution, and mix it evenly , and then evenly spread the mixed solution on the carbon felt anode, and finally put the anode plate into the saturated boric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

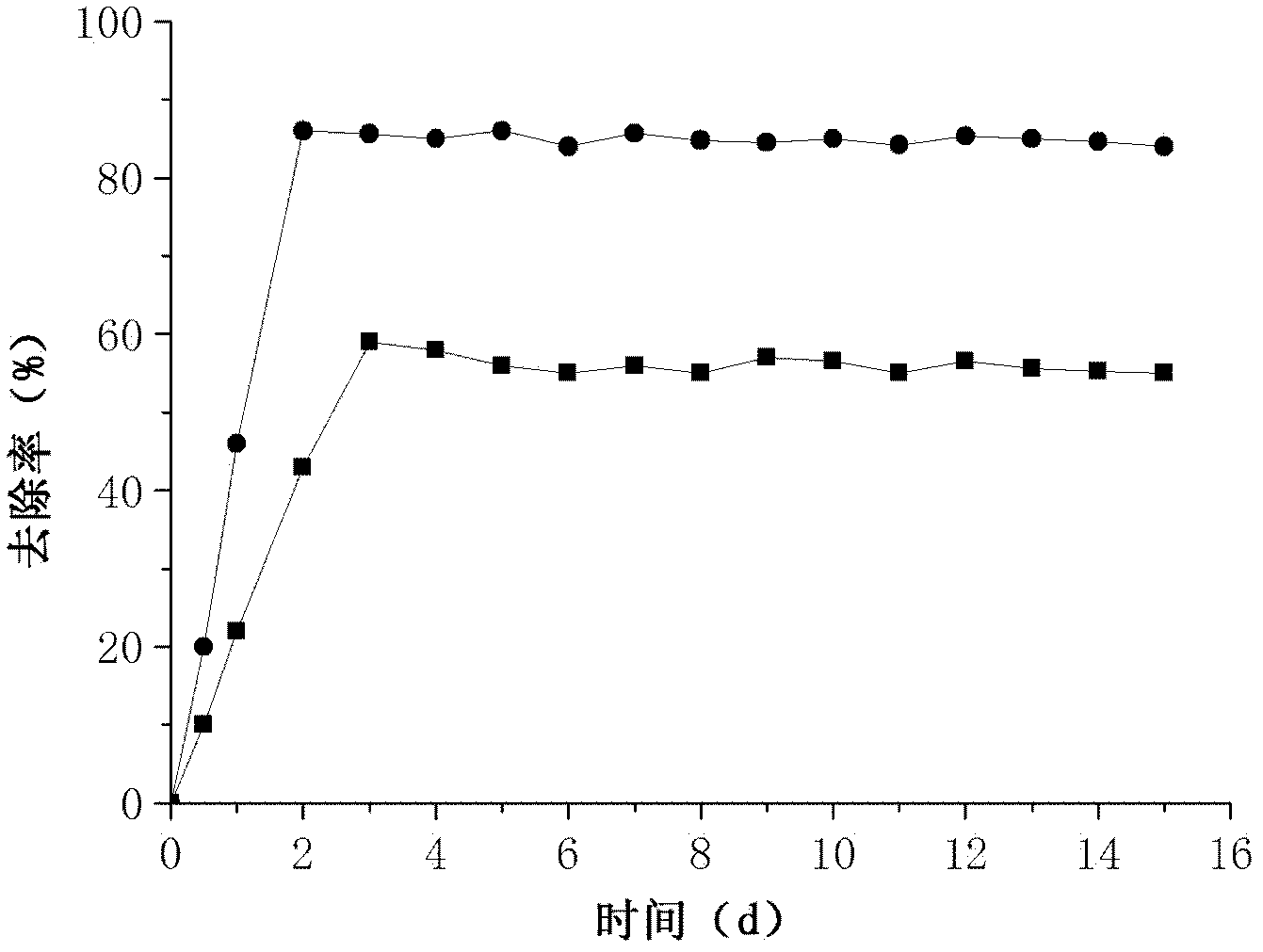

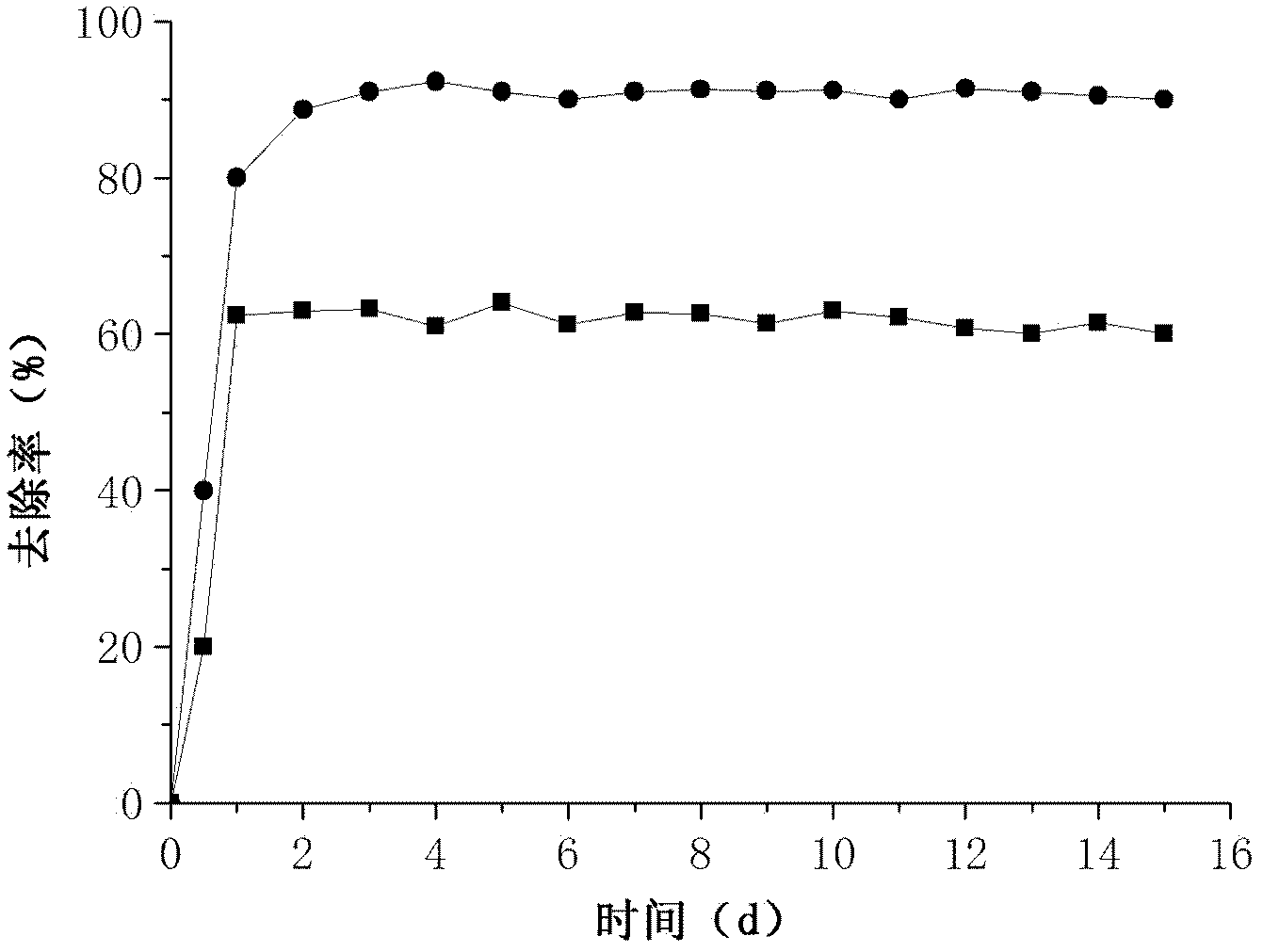

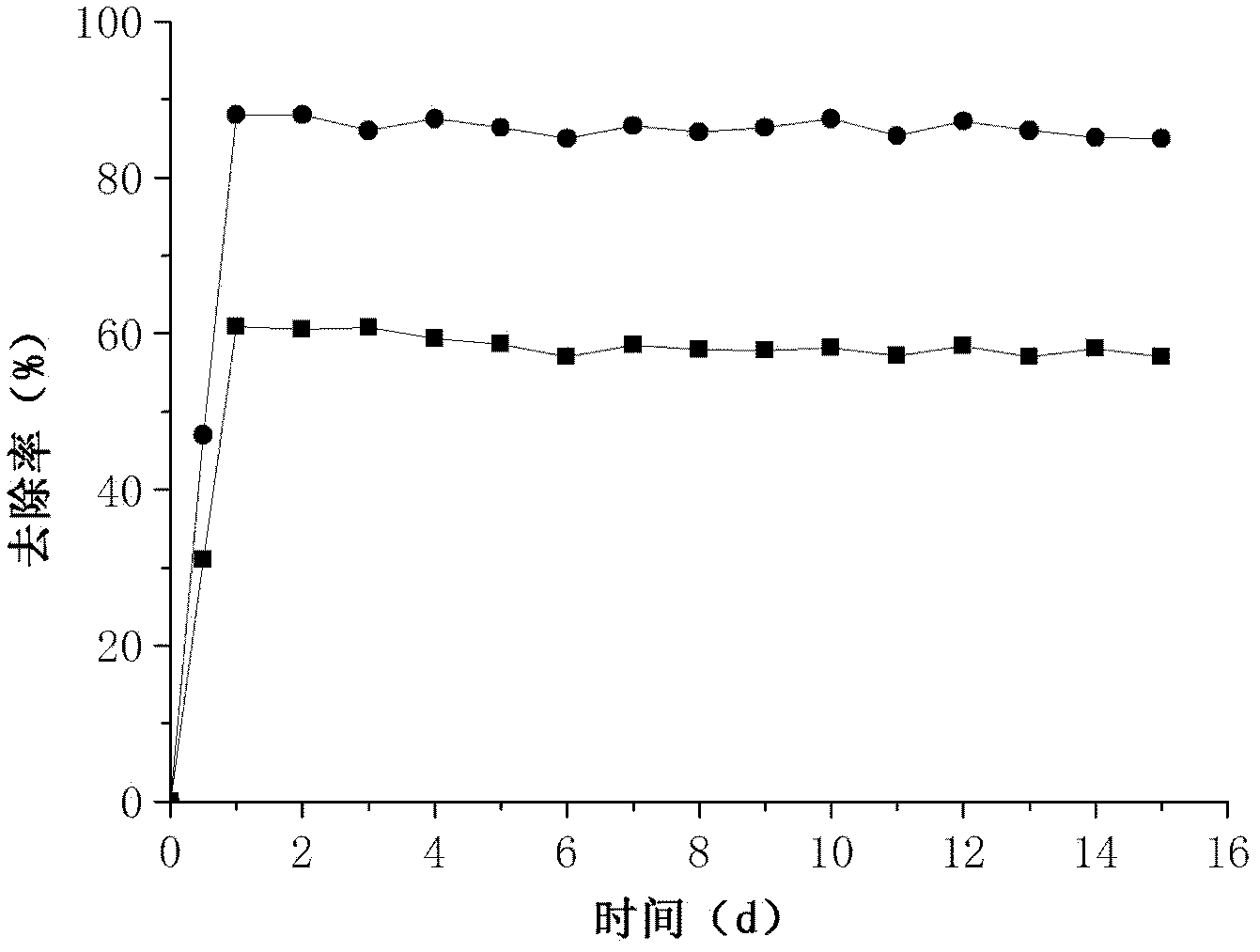

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com