Clarifying device and clarifying method for glass

A clarification device and glass technology, which is applied in the field of optical glass manufacturing, can solve the problems of large expansion and contraction changes of the clarification tank, easy damage to the platinum structure, unfavorable energy saving and consumption reduction, etc., so as to facilitate floating and overflow, reduce energy consumption, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

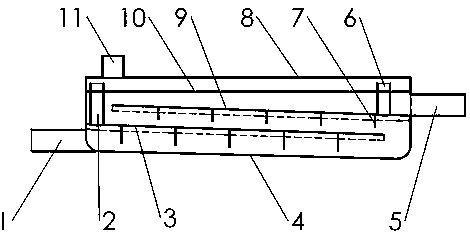

[0023] Such as figure 1 shown. A glass clarification device structure of the present invention includes an inlet pipe 1, a front exhaust pipe 2, a lower partition 3, a clarification tank 4, an outlet pipe 5, a rear exhaust pipe 6, a baffle 7, a tank cover 8, and an upper partition 9 and chimney11. The clarification tank 4 is a cuboid or U-shaped tank-shaped cavity with a tank cover. The inlet pipe 1 and the outlet pipe 5 are respectively welded at the front and rear ends, and are used as channels for the inflow and outflow of glass liquid. The lower dividing plate 3 and the upper dividing plate 9 are folded along the length direction into an arc or an inverted V shape with high middle part and low sides. The upper partitions 9 are respectively welded on three sides of the walls of the clarification tank 4 to form a multi-layer separation layer and extend the flow path of the glass liquid in the clarification tank 4 . The top of one end of the lower partition 3 and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com