Circulating fluidized bed boiler for burning low-heat-value high-ash fuel

A circulating fluidized bed, low calorific value technology, applied in the direction of burning fuel, fluidized bed combustion equipment, combustion method, etc., can solve the problems of reducing the thermal efficiency of boilers, difficult to stabilize combustion, etc., and increase the gas-solid heat exchange time. , increase the flow distance, and achieve the effect of gas-solid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

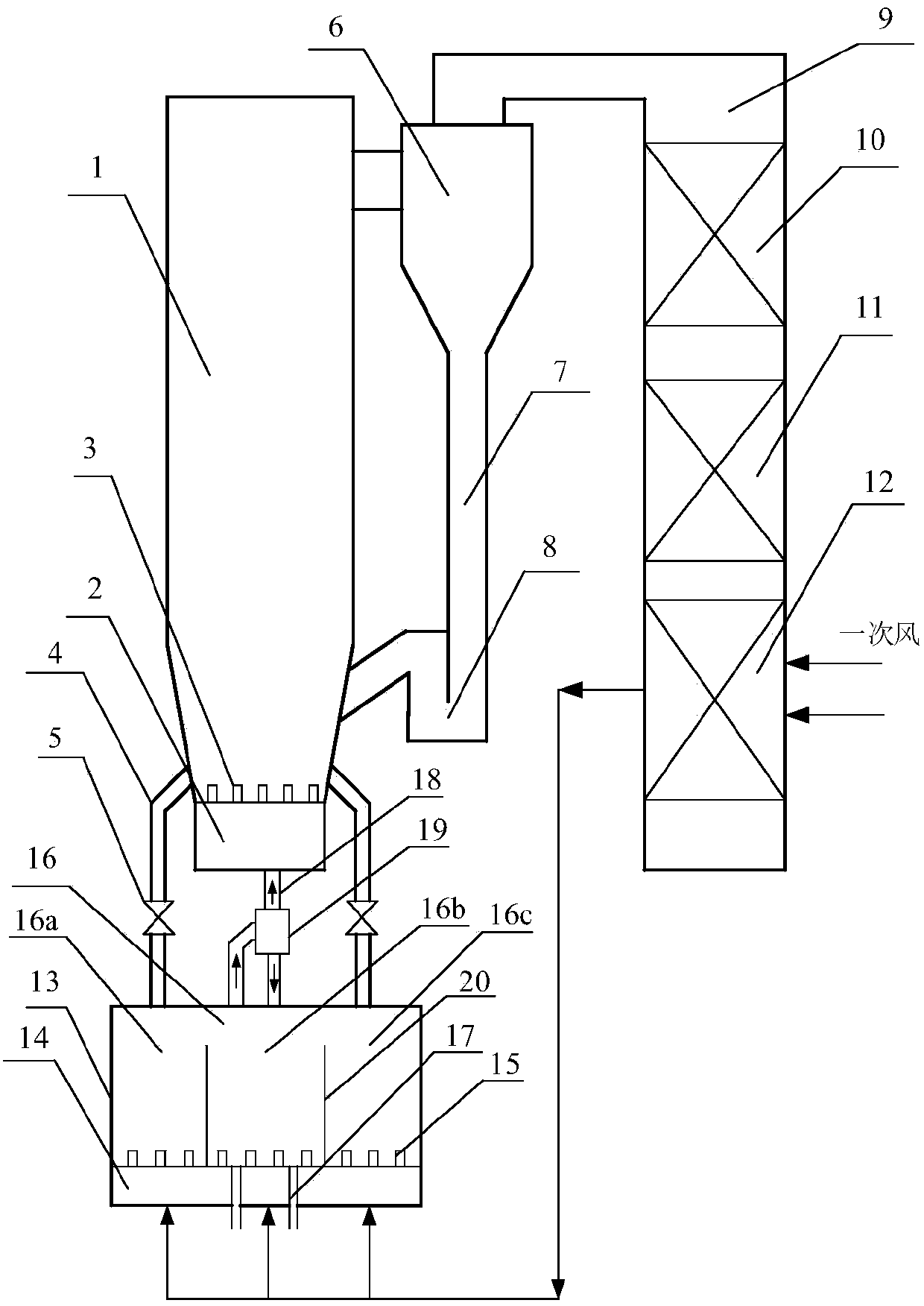

[0014] The specific structures, principles and implementation methods of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] figure 1 It is a schematic diagram of the structural principle of an embodiment of a circulating fluidized bed boiler for burning fuel with low calorific value and high ash content, which includes a furnace 1, a primary air chamber 2, a cyclone separator 6, a material leg 7, a return valve 8 and The tail flue 9; the slag discharge pipe 4 is arranged on the side of the bottom of the furnace 1, the air cap 3 is evenly arranged on the upper part of the primary air chamber 2, and the tail flue 9 contains a superheater 10, an economizer 11 and an air preheater 12; in the primary air chamber 2 A gas-solid heat exchange bed 13 is added below, the primary air chamber 2 is connected to the top of the gas-solid heat exchange bed 13 through a connecting pipe 18, and a gas-solid separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com