Explosion-proof valve

A technology of explosion-proof valves and valve ports, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to extinguish flames, achieve the effects of eliminating continuous deflagration, good performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

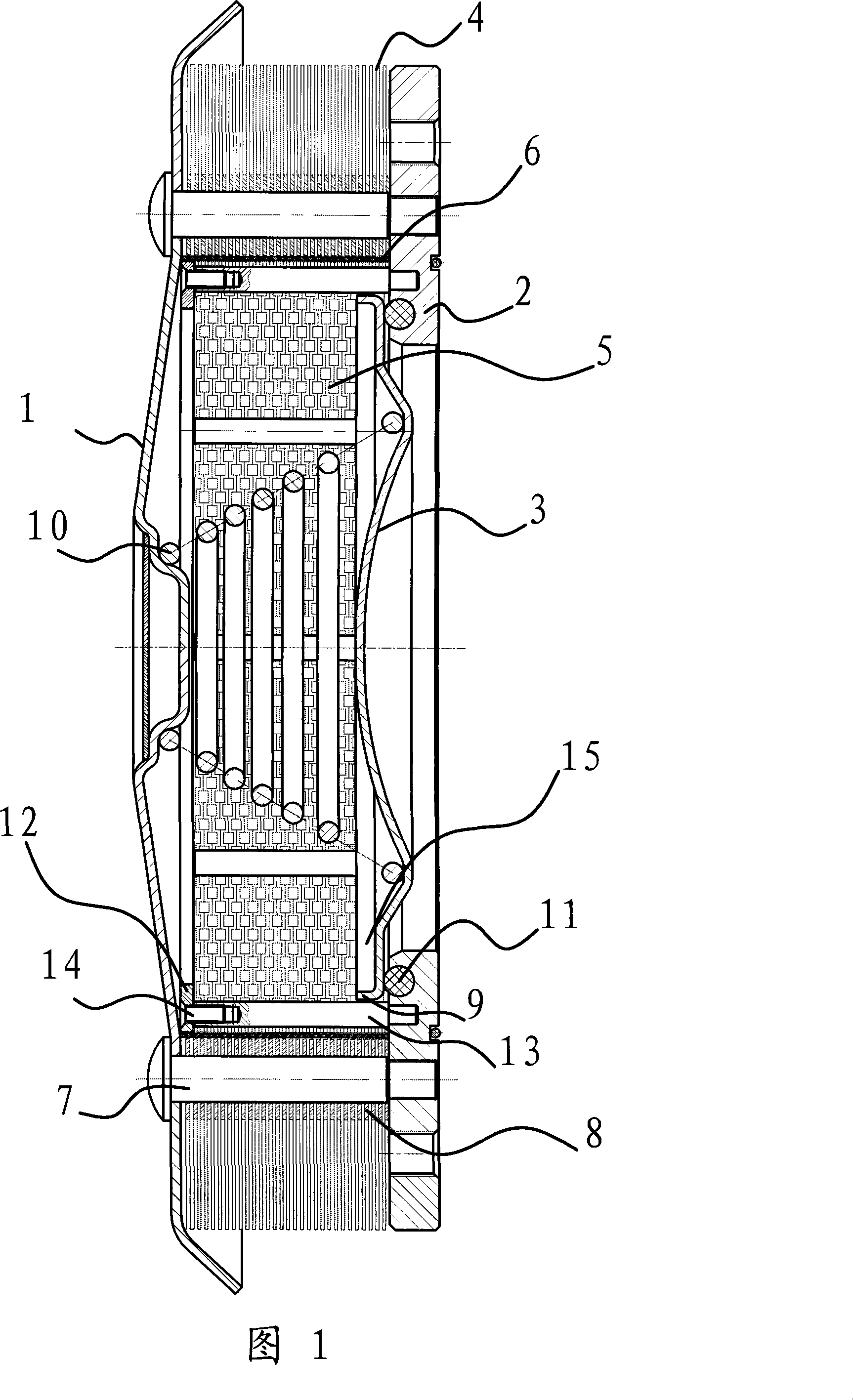

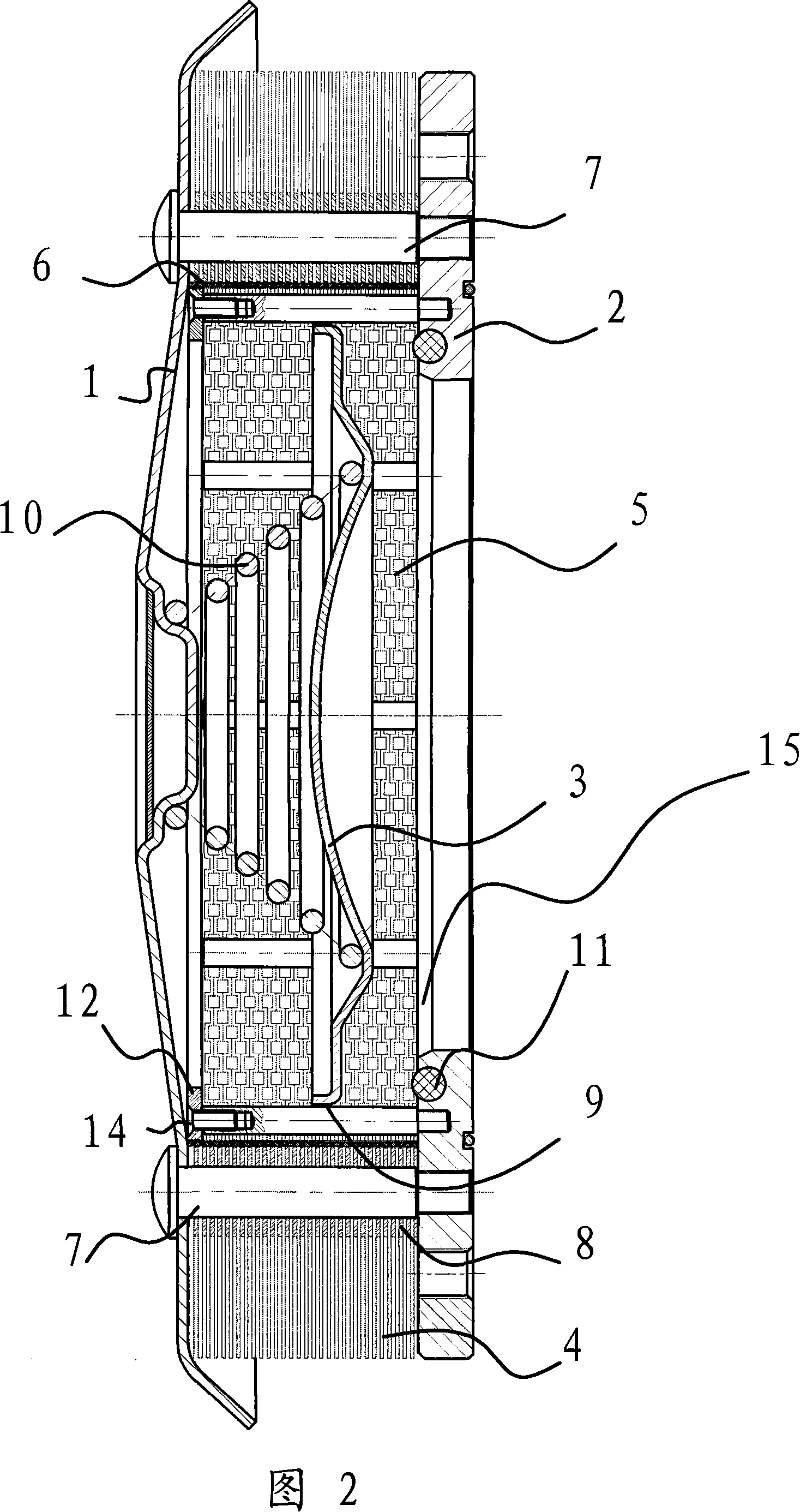

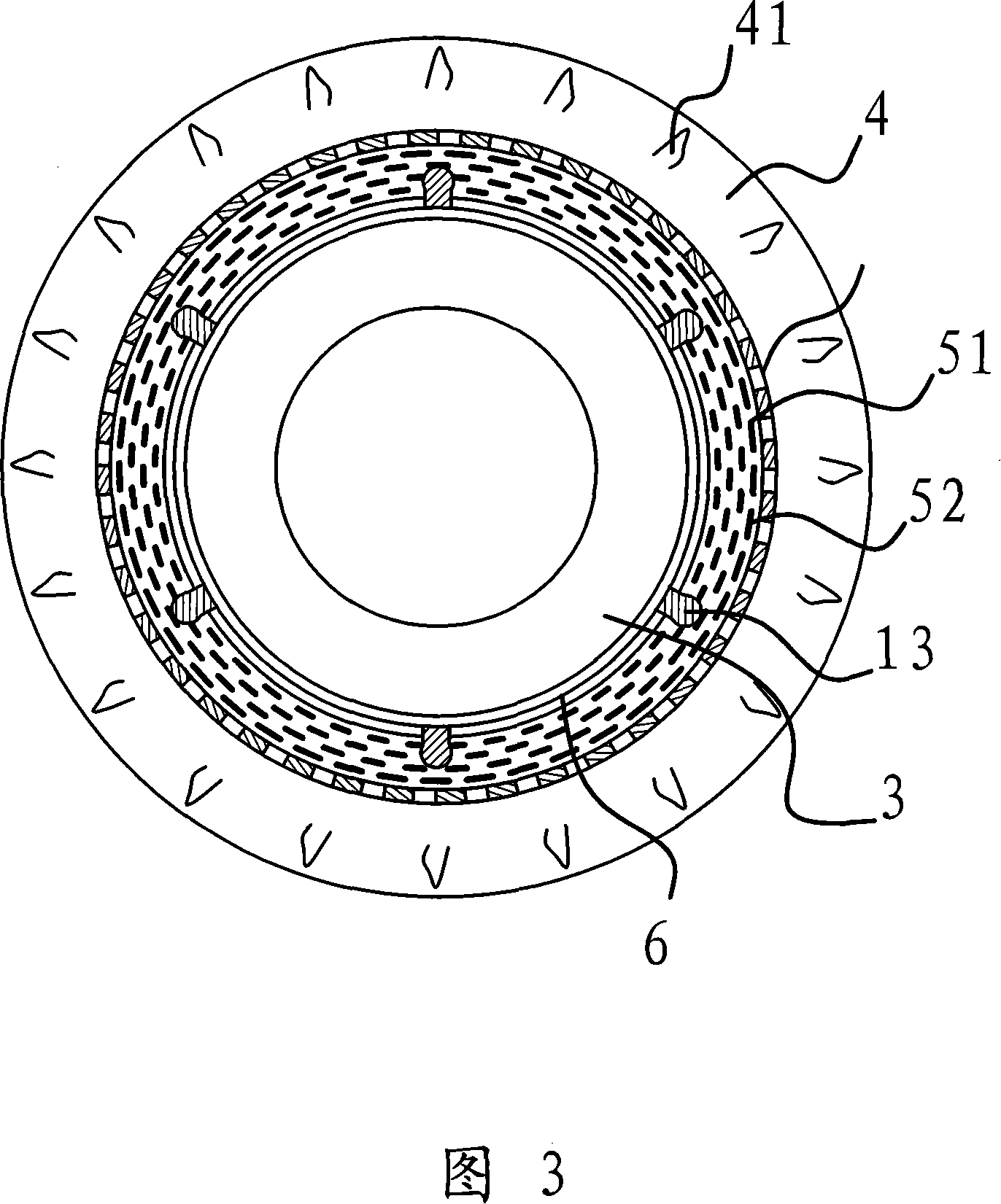

[0025] As shown in Figure 1, Figure 2 and Figure 3, this explosion-proof valve is applied on the crankcase to release the high-pressure airflow and high-temperature flame generated by the explosion when the explosion occurs inside the crankcase. While releasing, the pressure is weakened and the flame is extinguished in the explosion-proof The valve then closes to prevent air from entering. The explosion-proof valve includes a panel 1, a seat plate 2, a valve port sealing plate 3, a flame retardant sheet 4, a flame retardant 5 and a flame retardant ring 6 and the like.

[0026] Specifically, the seat plate 2 is ring-shaped, and can be connected to the crankcase through the seat plate 2. The panel 1 is disc-shaped, and a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com