Easily cleaned condenser

A condenser, easy-to-clean technology, used in steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

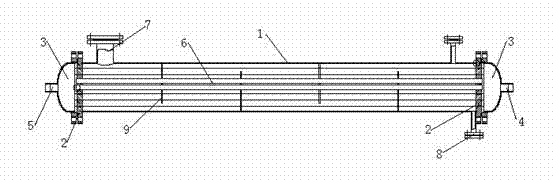

[0011] Combine below figure 1 Specific description embodiment:

[0012] An easy-to-clean condenser, comprising a shell 1, the two ends of the shell 1 are provided with baffles 2 that can seal the shell 1, and each of the baffles 2 is connected with a head 3, and one of the The head 3 is provided with a water inlet 4, the other head is provided with a water outlet 5, and the housing 1 is provided with a heat exchange tube 6 communicating with the water inlet 4 and the water outlet 5, and the said The upper part of the housing 1 is provided with a steam inlet 7, the lower part of the housing 1 is provided with a condensate outlet 8, and the housing 1 is provided with staggered installations between the steam inlet 7 and the condensate outlet 8 to prolong the steam flow. The baffle plate 9 of the path.

[0013] Preferably, the steam inlet 7 is located near the water outlet 5 , and the condensate outlet 8 is located near the water inlet 4 .

[0014] During operation, steam prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com