Crystallizer for hydrolyzing carnallite to prepare potassium chloride

A crystallizer and potassium chloride technology, which is applied in the field of salt chemical industry, can solve the problem that the crystallizer cannot fully hydrolyze large-size carnallite, and achieve the effects of reducing raw material and energy consumption, increasing residence time, and extending the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

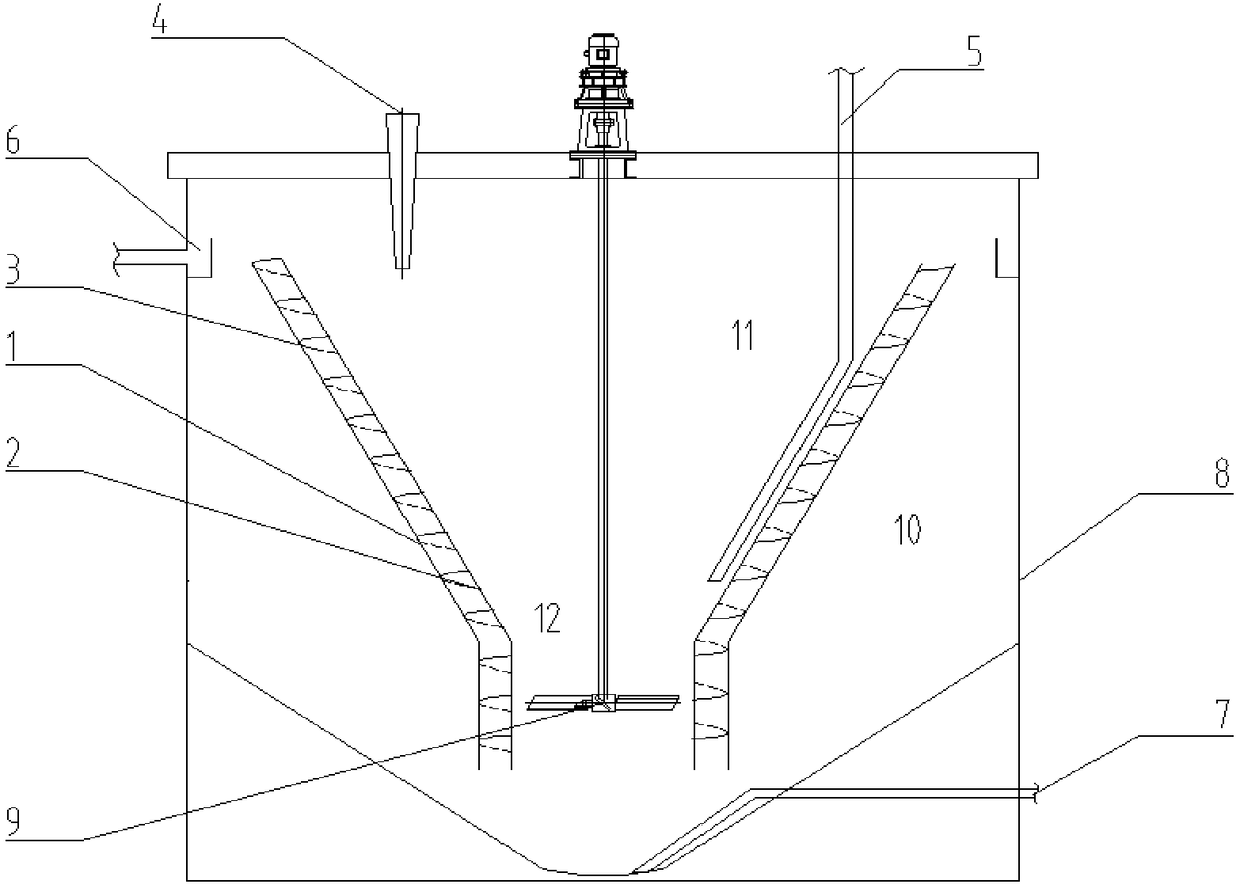

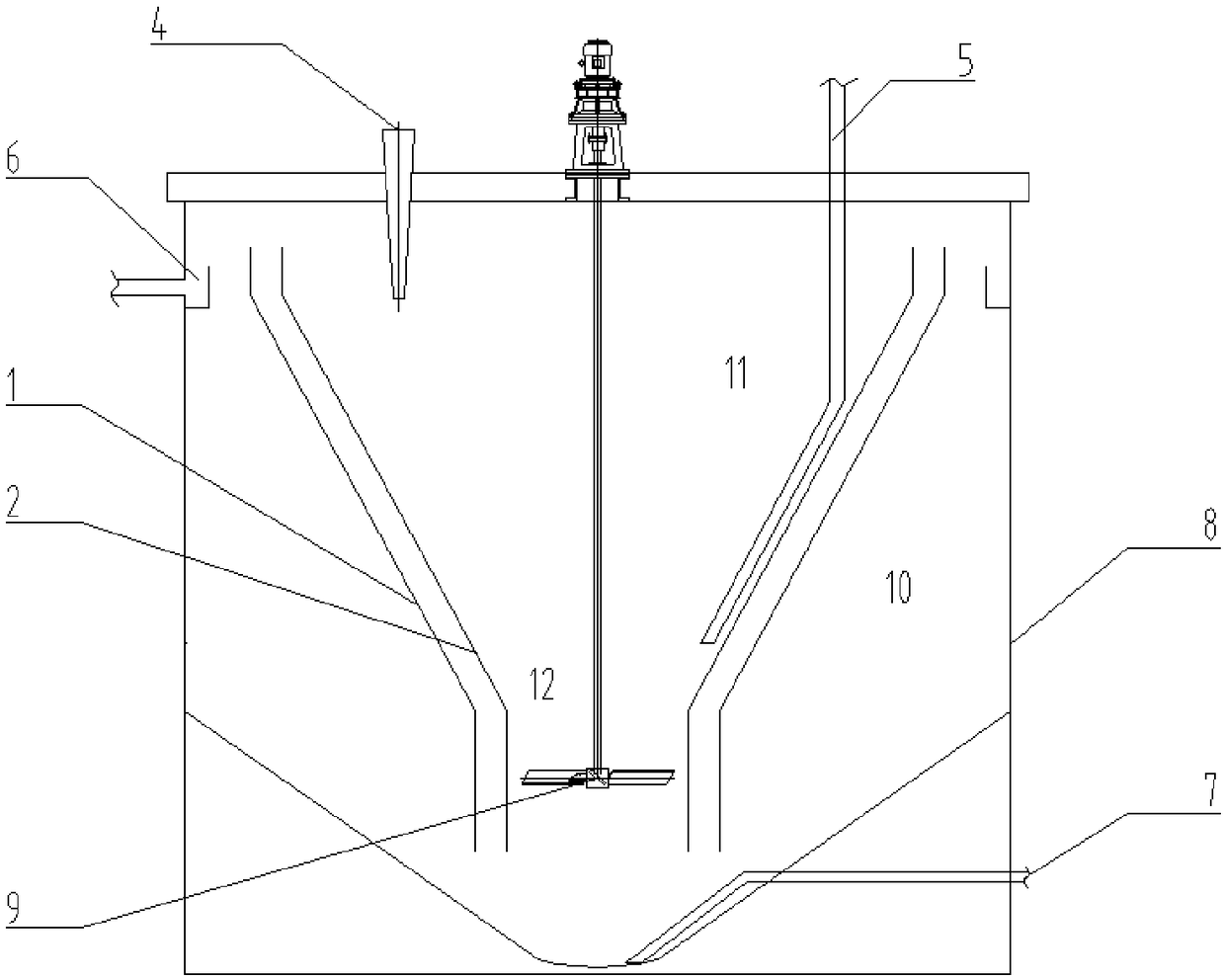

[0039] The crystallizer of the present embodiment is as figure 1 As shown, the cylindrical shell 8 of the crystallizer is 8.0m high and 24m in diameter, the upper part of the inner cylinder 2 is 3.0m high, the diameter of the upper port is 16.0m, and the diameter of the lower port is 8.8m. The angle between the extension lines of the sides of the rectangle is 39.8°, and the lower part of the inner tube 2 is a cylindrical structure (the shape of the longitudinal section is rectangular), and its lower part is 2.0m high, 2.0m away from the bottom of the elliptical cone shell of the crystallizer.

[0040] The upper part of the outer cylinder 1 is 3.0m high, the diameter of the upper port is 17.5m, and the diameter of the lower port is 10.5m. The angle between the inverted tapered side of the outer cylinder 1 and the extension line of the rectangular side is 40.6°. Shaped structure (longitudinal cross-sectional shape is rectangular), its lower part is 1.5m high, 2.5m away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com