Rotary injection type evaporation tube of combustion chamber of micro engine

A technology of rotary injection and evaporation tube, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of unstable combustion and unsatisfactory mixing degree, and achieve the effect of simple structure, easy processing and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing:

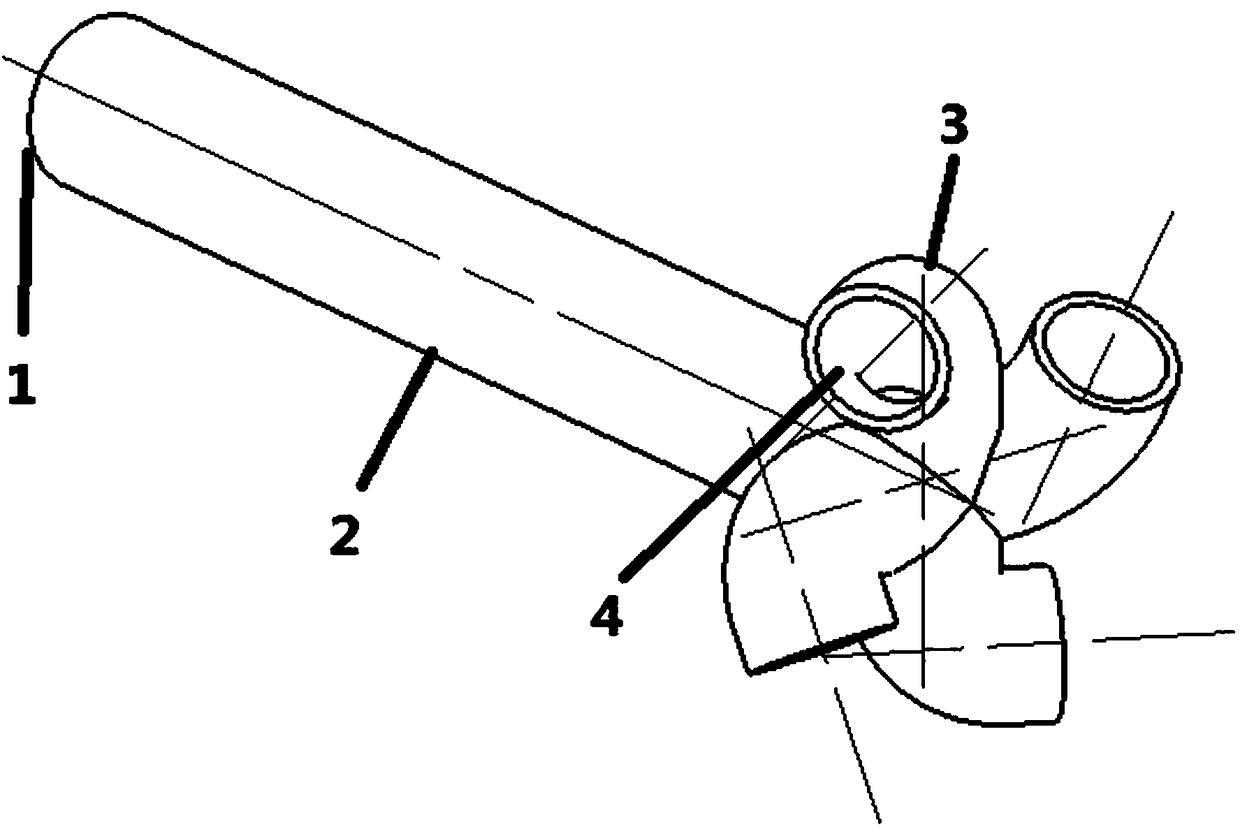

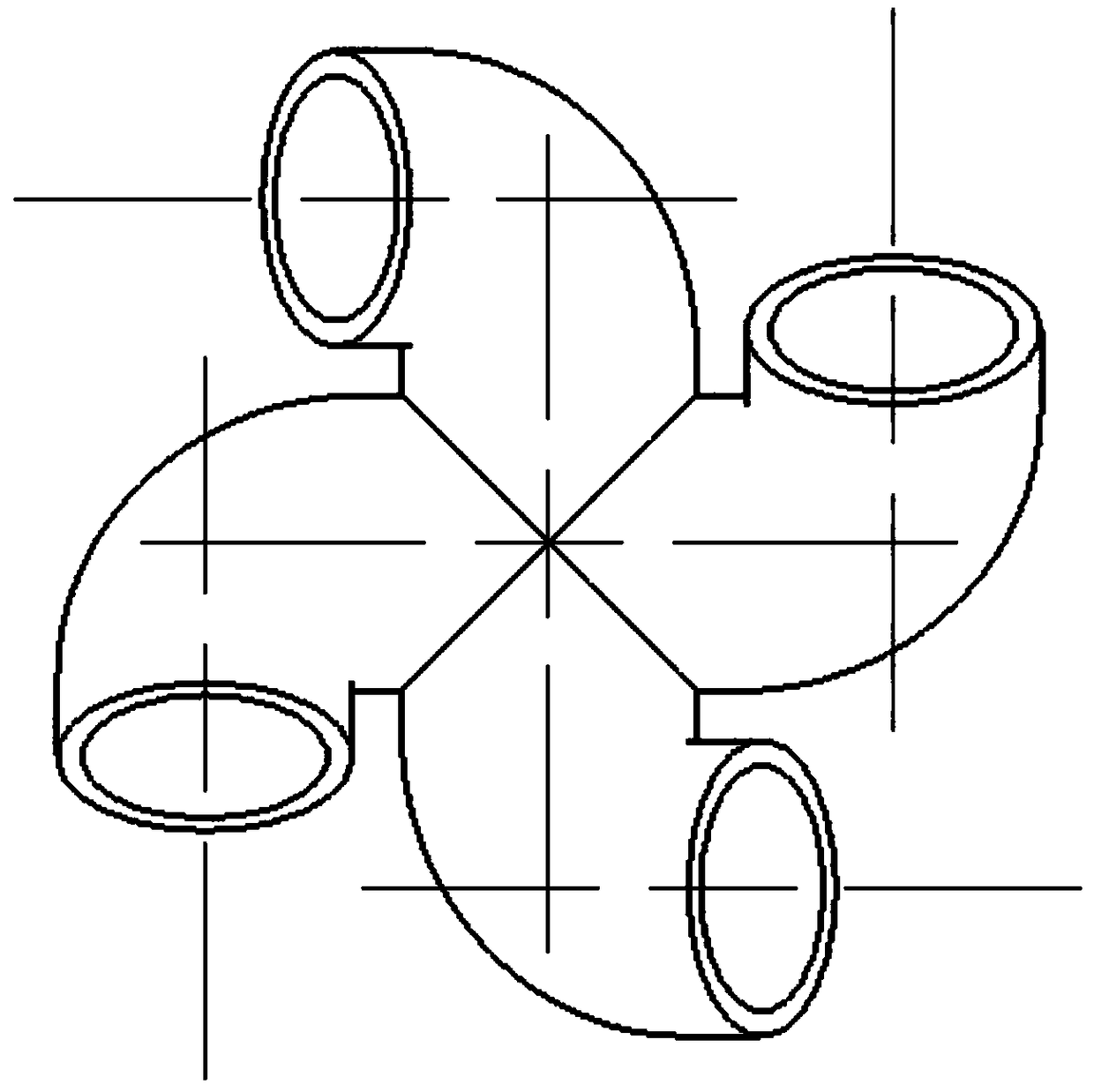

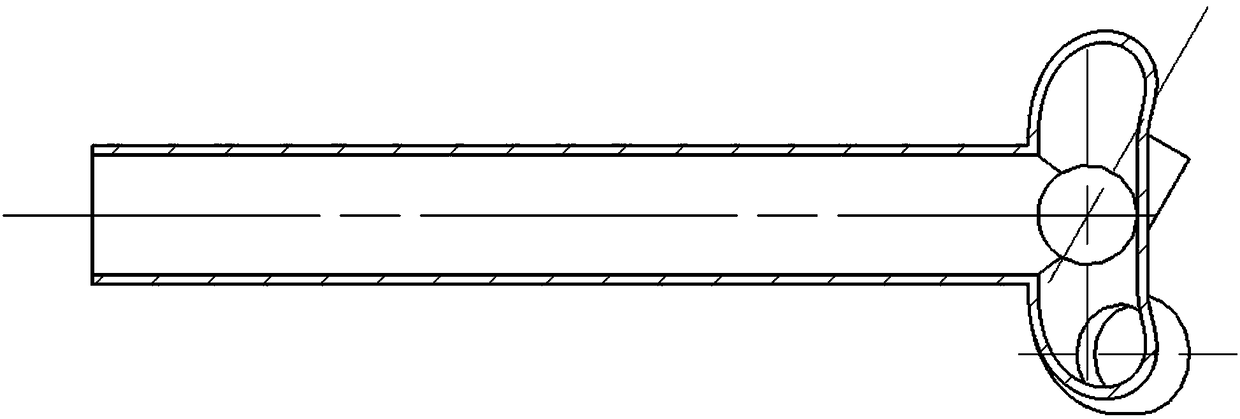

[0020] combine figure 1 , figure 2 and image 3 , The present invention provides a micro-engine combustor rotary jet evaporator tube structure that can increase the mixed degree of fuel and air and stabilize the air flow. figure 1 is the overall schematic diagram of the evaporation tube, figure 2 It is the right view of the evaporation tube seen from the direction of the nozzle, it can be clearly seen that the four rotating branch pipeline structures are connected to the evaporation tube vertically in turn, image 3 It is a cross-sectional view of the evaporation tube, and the connection between the branch pipeline structure and the inside of the evaporation tube can be seen.

[0021] according to figure 1 As shown, the mixed flow of fuel and air enters the evaporator tube (2) from the evaporator tube inlet (1), and in the evaporator tube (2), the fuel is heated and ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com