Tomato side branch pruning robot

A robot and tomato technology, applied in the field of tomato side branch pruning robot, can solve the problems of high work intensity, high pruning cost, and increased content of workers, and achieve the effects of saving production and operating costs, reducing space occupation, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

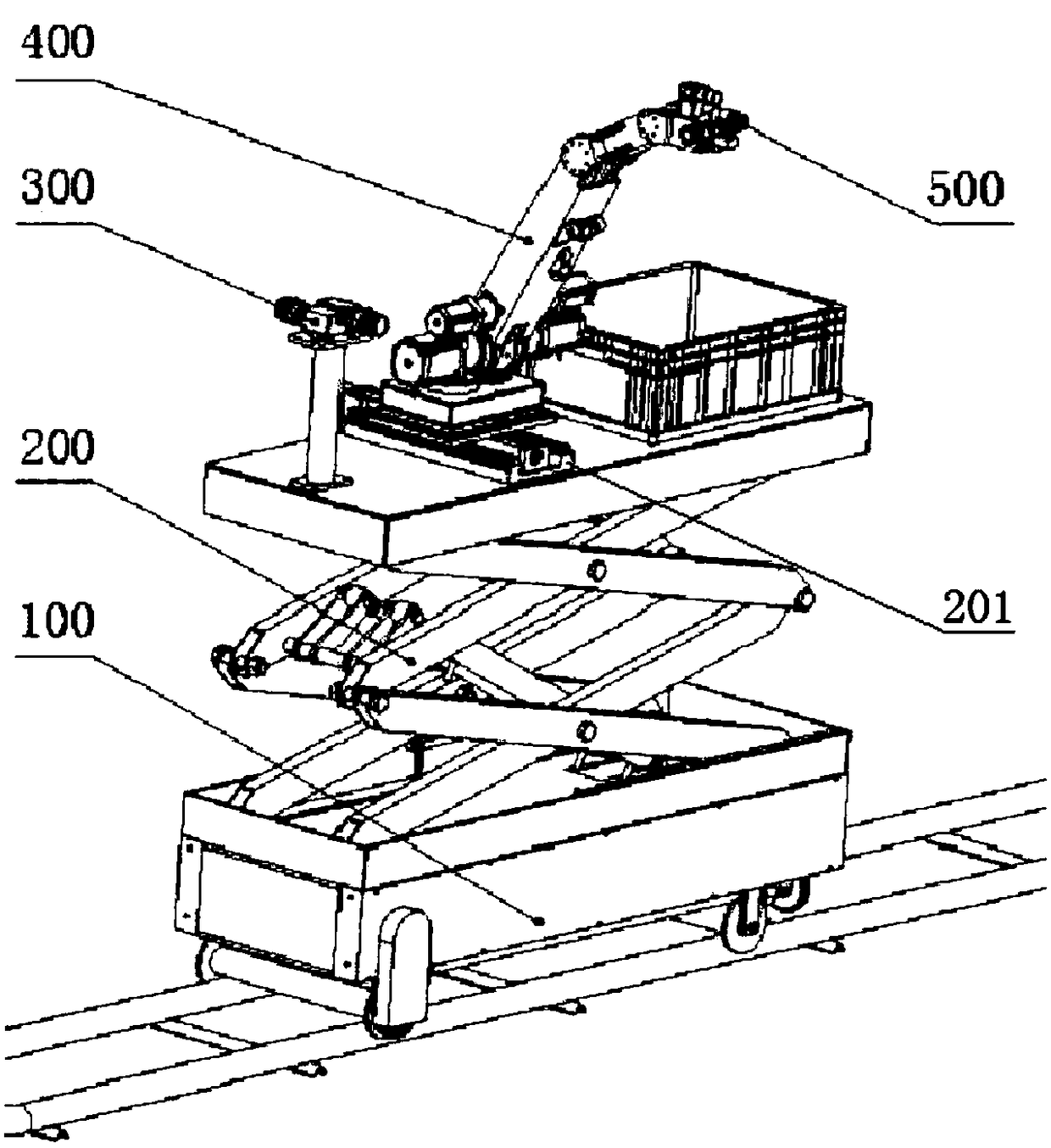

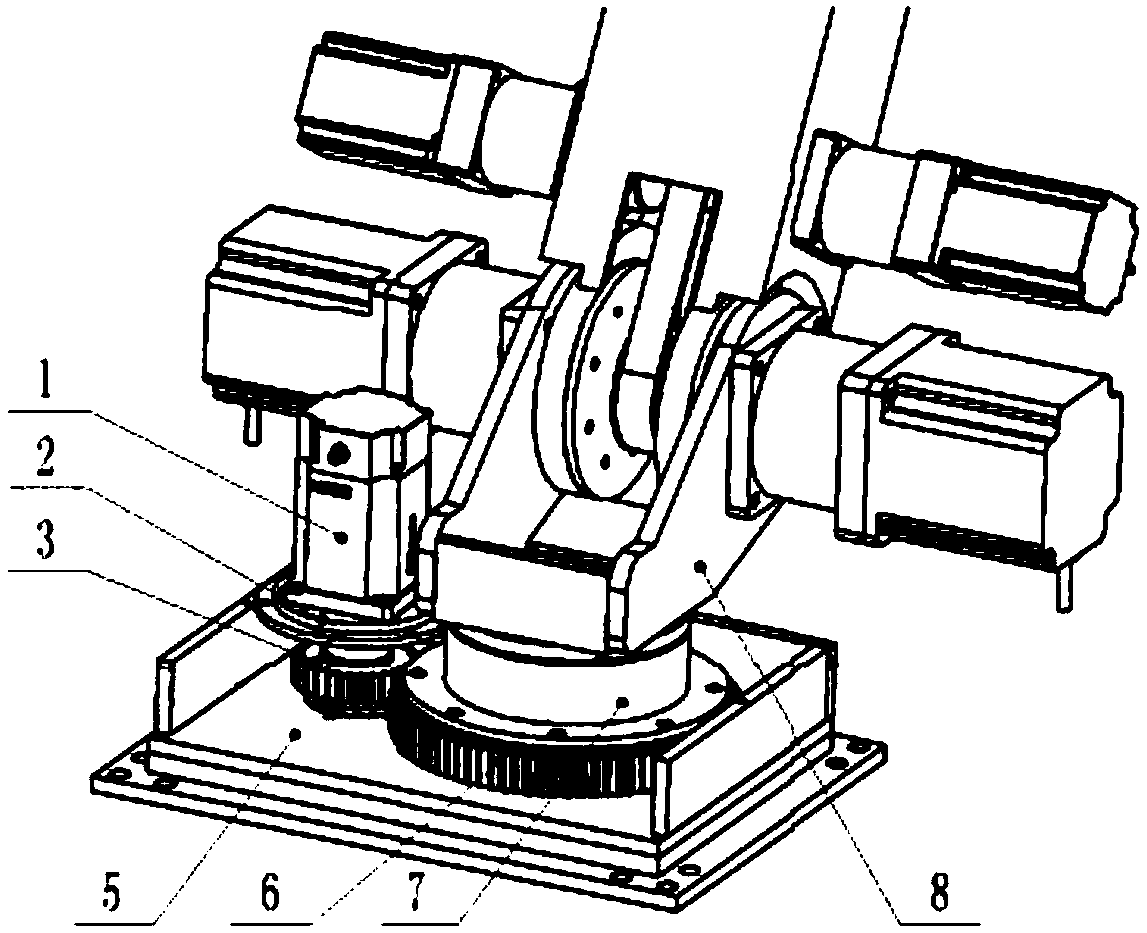

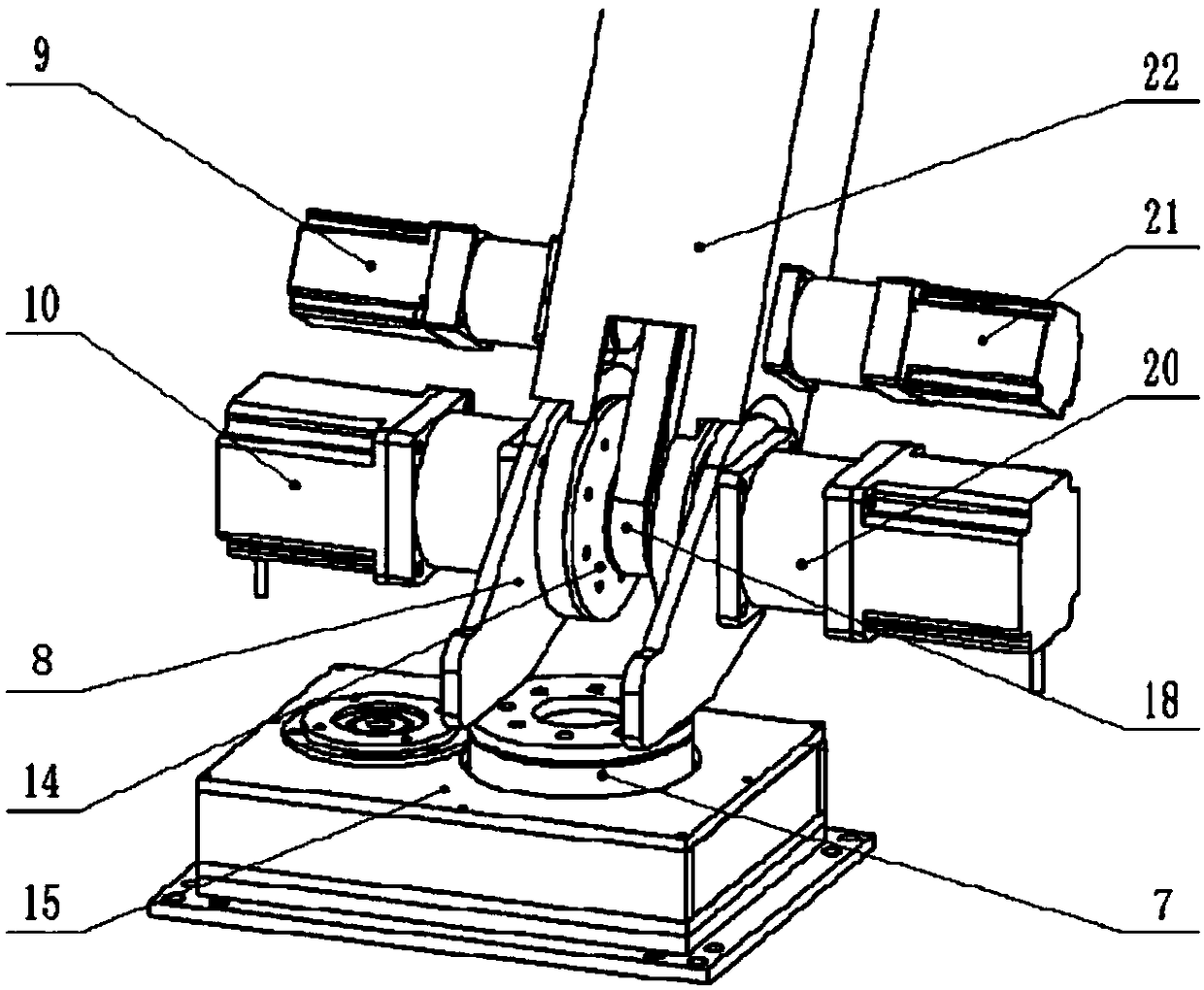

[0028] Example. Tomato side branch pruning robot, constituted as figure 1 As shown, the walking device 100 is included, the top of the walking device 100 is provided with a lifting platform 200, the lifting platform 200 is provided with a first vision system 300 and a manipulator 400, and one end of the manipulator 400 is connected with a laser cutting device 500; the manipulator 400 includes a fixed The screw sliding table device 201 on the top of the lifting platform 200 is fixedly connected with the manipulator base 5, the manipulator base 5 is provided with a base fixing flange 2, and the top of the base fixing flange 2 is provided with a servo motor 1, The outer side of the output shaft of the servo motor 1 passes through the bearing. The bearing at this place can be connected with a thrust ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com