Hedgerow integral shaping cutter capable of automatically adjusting shapes

An overall shape and automatic adjustment technology, applied to hedge trimming equipment, etc., can solve the problems of low efficiency of shape pruning and poor adaptability, and achieve the effects of reducing maintenance costs and purchase costs, improving efficiency, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

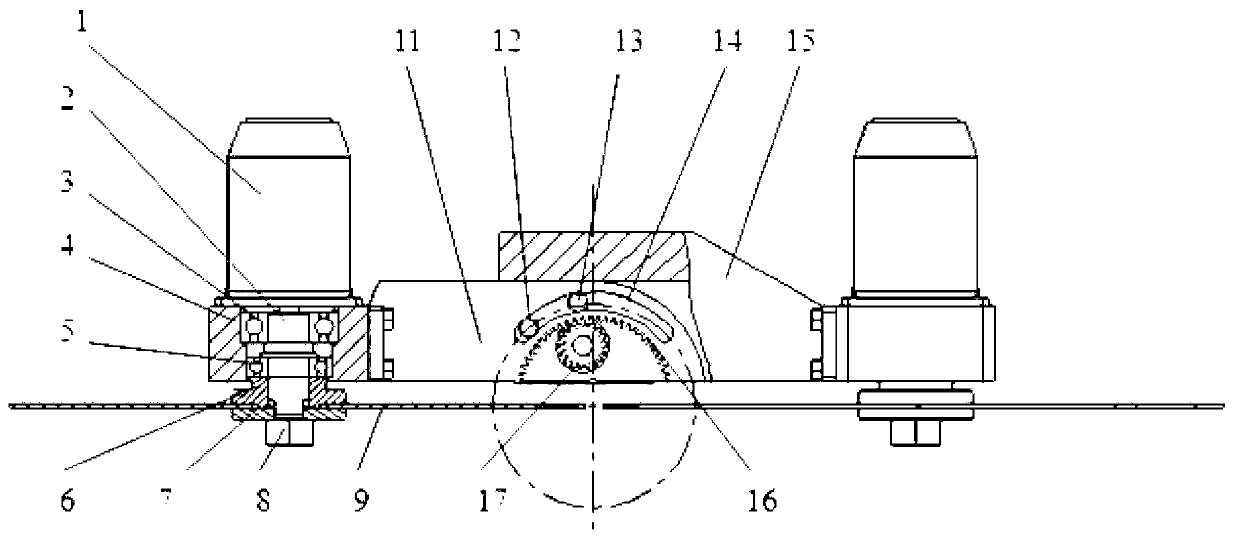

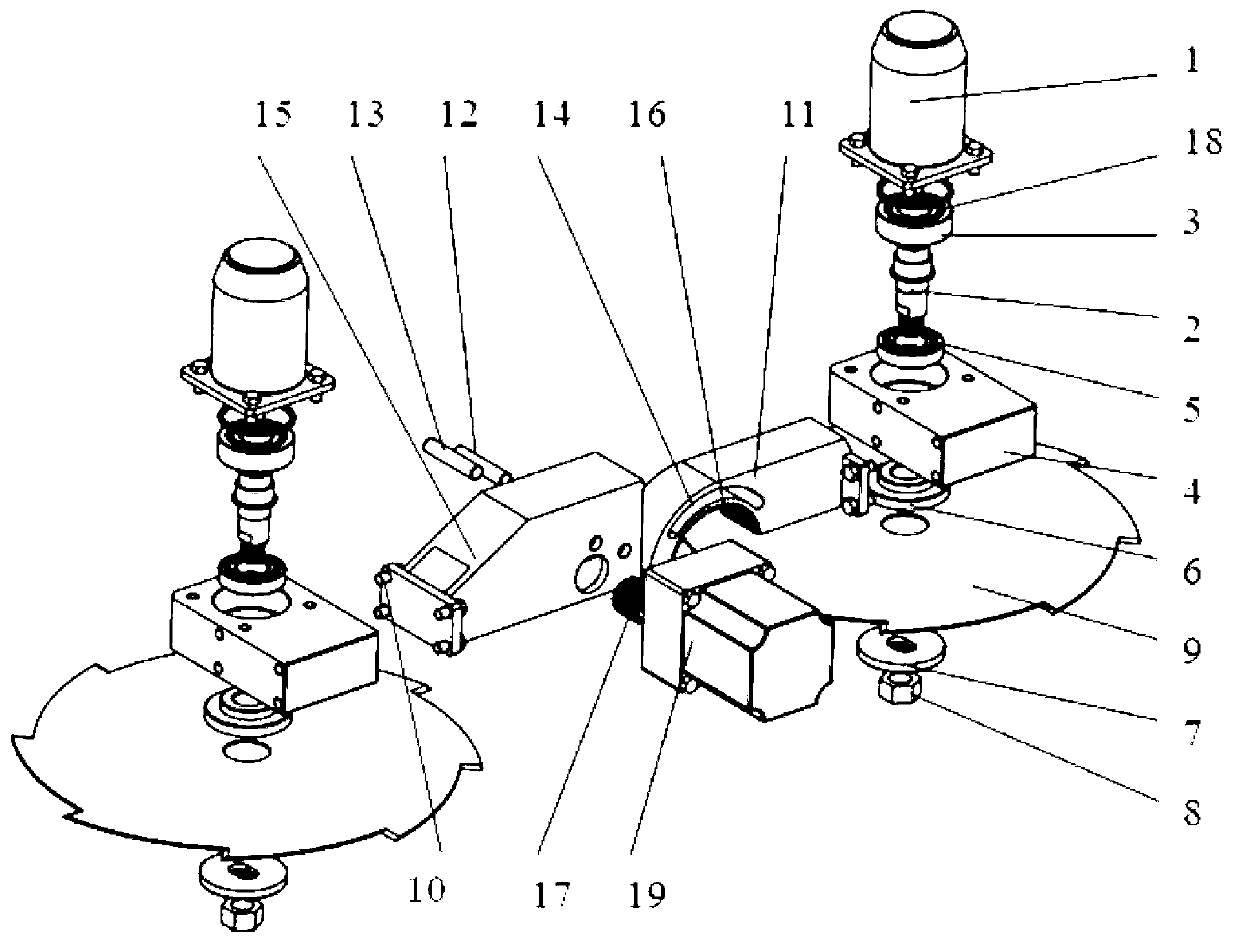

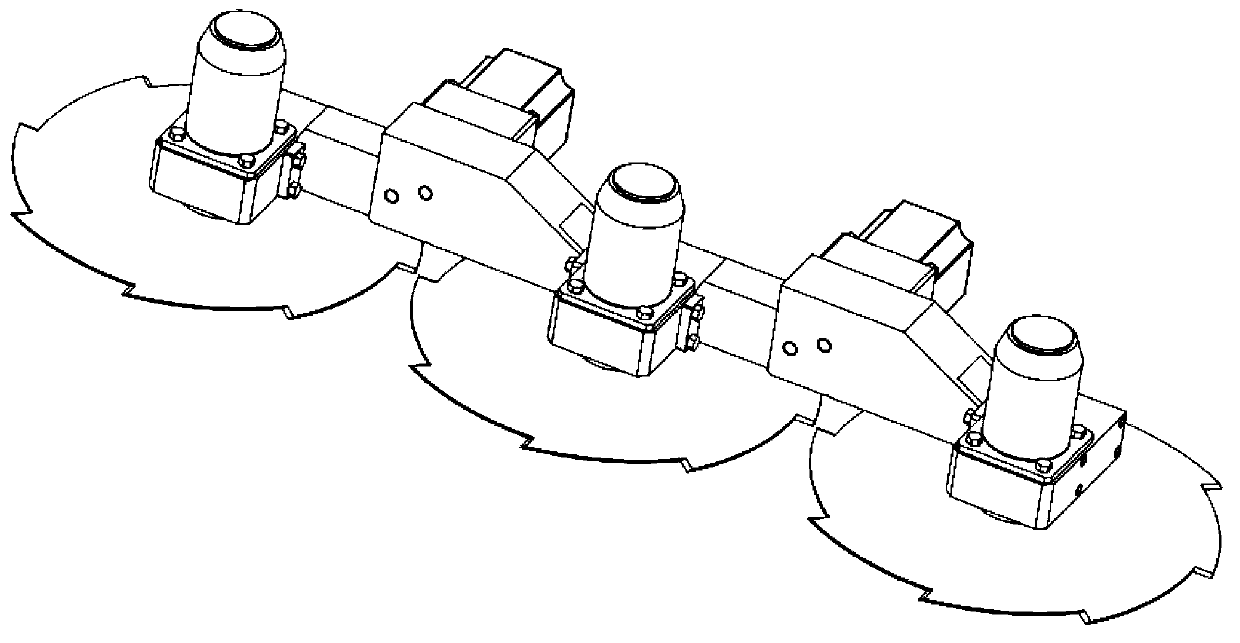

[0020] Refer to attached figure 1 with figure 2 , the overall hedgerow molding tool that can automatically adjust the shape of the present invention includes a main module, a grafting module and an angle adjustment mechanism, the main module and the grafting module, and the grafting module and the grafting module are connected by an angle adjustment mechanism, the specific structure and connect as:

[0021] The main module includes a box body 4, the upper end bearing 3 is installed on the upper end bearing position of the box body 4, the lower end bearing 5 is installed on the lower end bearing position of the box body 4, and the upper end and the lower end of the cutterhead rotating shaft 2 are respectively inserted through the upper end bearing 3 And the lower end bearing 5, the flange 6 is installed on the lower end of the cutter he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com