Trapped-vortex combustor with swirlers

A swirler and combustion chamber technology, applied in the field of vortex combustion chambers, can solve the problems of weak strength in the recirculation zone, insufficient vortex stability, and the degree of oil-gas mixing in the concave cavity needs to be improved, so as to achieve good combustion, stable flame, and improved The effect of the degree of atomization and the degree of oil-air mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing:

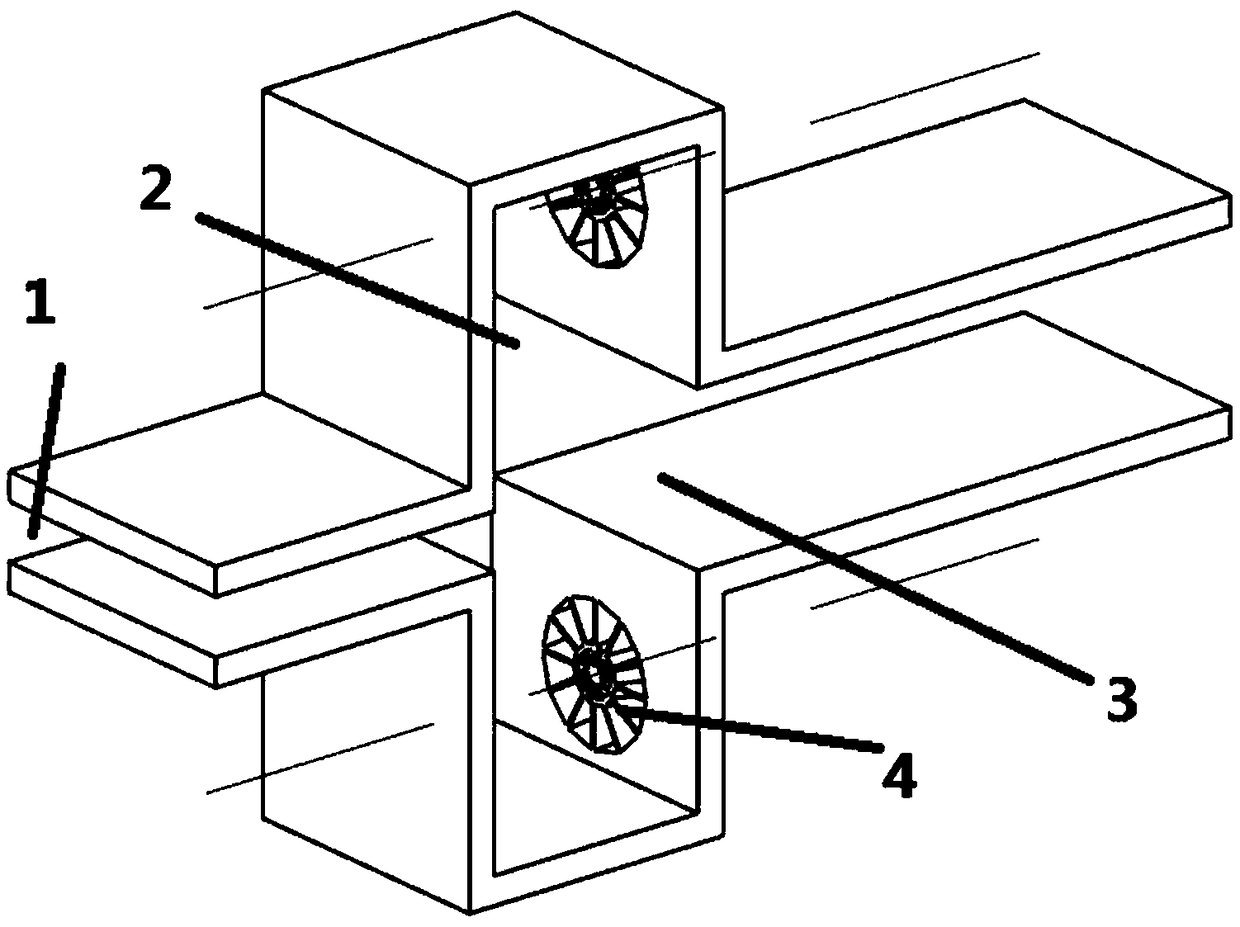

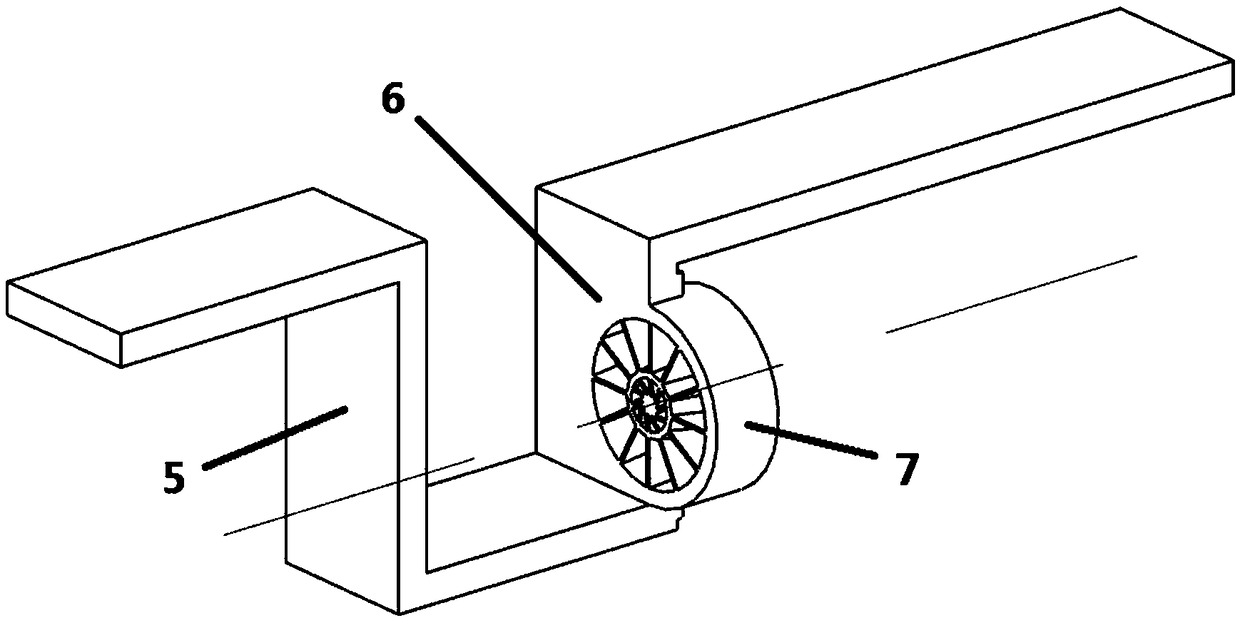

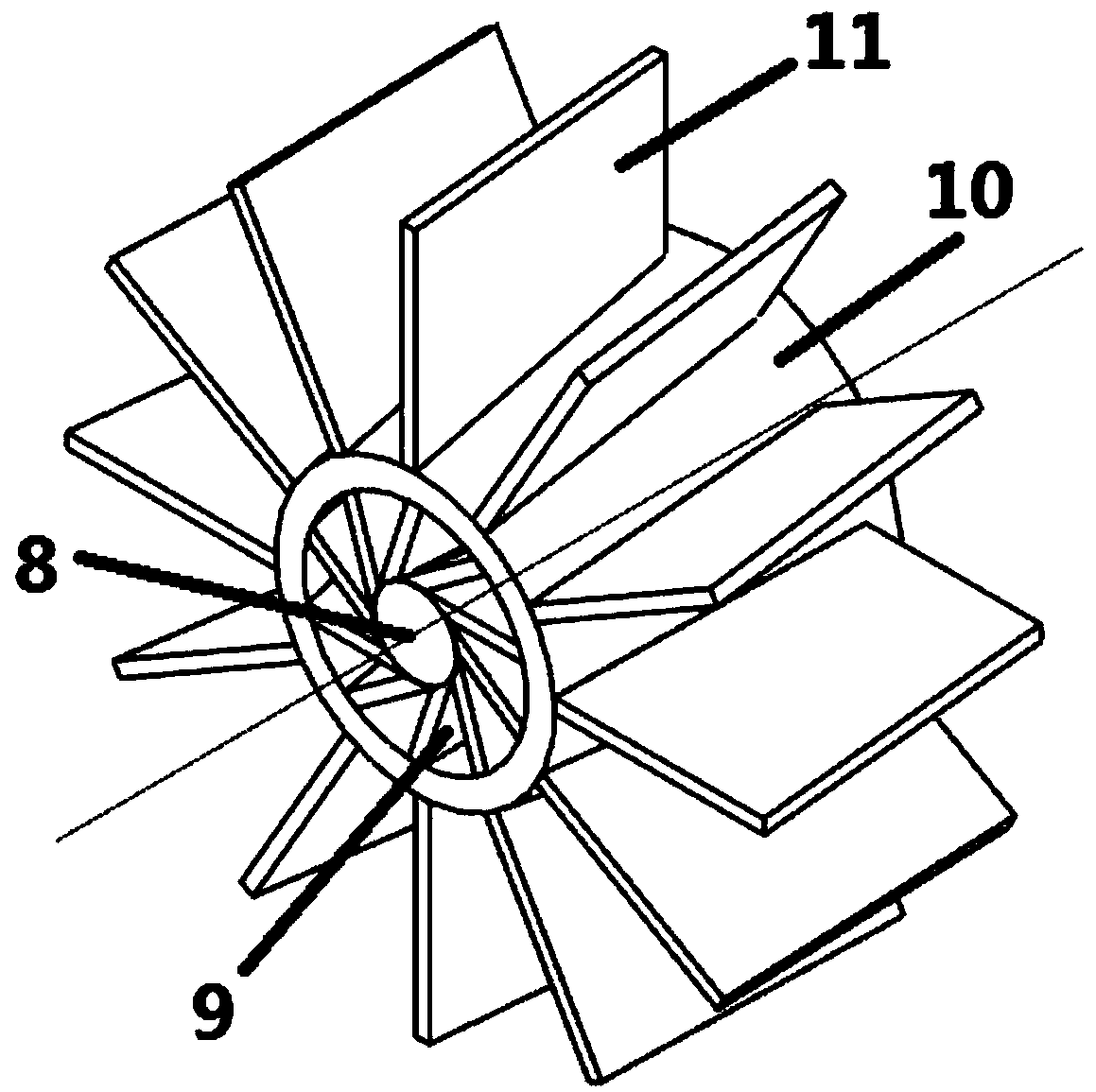

[0020] combine figure 1 , figure 2 , image 3 , the present invention arranges an axial swirler on the rear wall of the cavity of the trapped vortex combustion chamber. figure 1 It is an overall schematic diagram of a trapped vortex combustor with a swirler, figure 2 It is a partial sectional view of a trapped vortex combustor with a swirler, image 3 It is a partial schematic diagram of a trapped vortex combustor with a swirler.

[0021] Such as figure 1 As shown, oil and gas in the trapped vortex zone enter into two symmetrical concave cavities (2) respectively through two swirlers (4) distributed symmetrically with respect to the axis of the combustion chamber. Such as figure 2 As shown, the peripheral cylindrical sleeve (7) of the cyclone is connected with the rear wall (6) of the cavity. Such as image 3 As shown, since the primary cyclone blade (9) and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com