Bionic straight-line-rib-row type tiny staggered alveolar heat exchanger core and heat exchanger

A heat exchanger, linear technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of difficult to balance heat exchange performance and micro volume, so as to reduce the working fluid and reduce Effect of volume and running weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

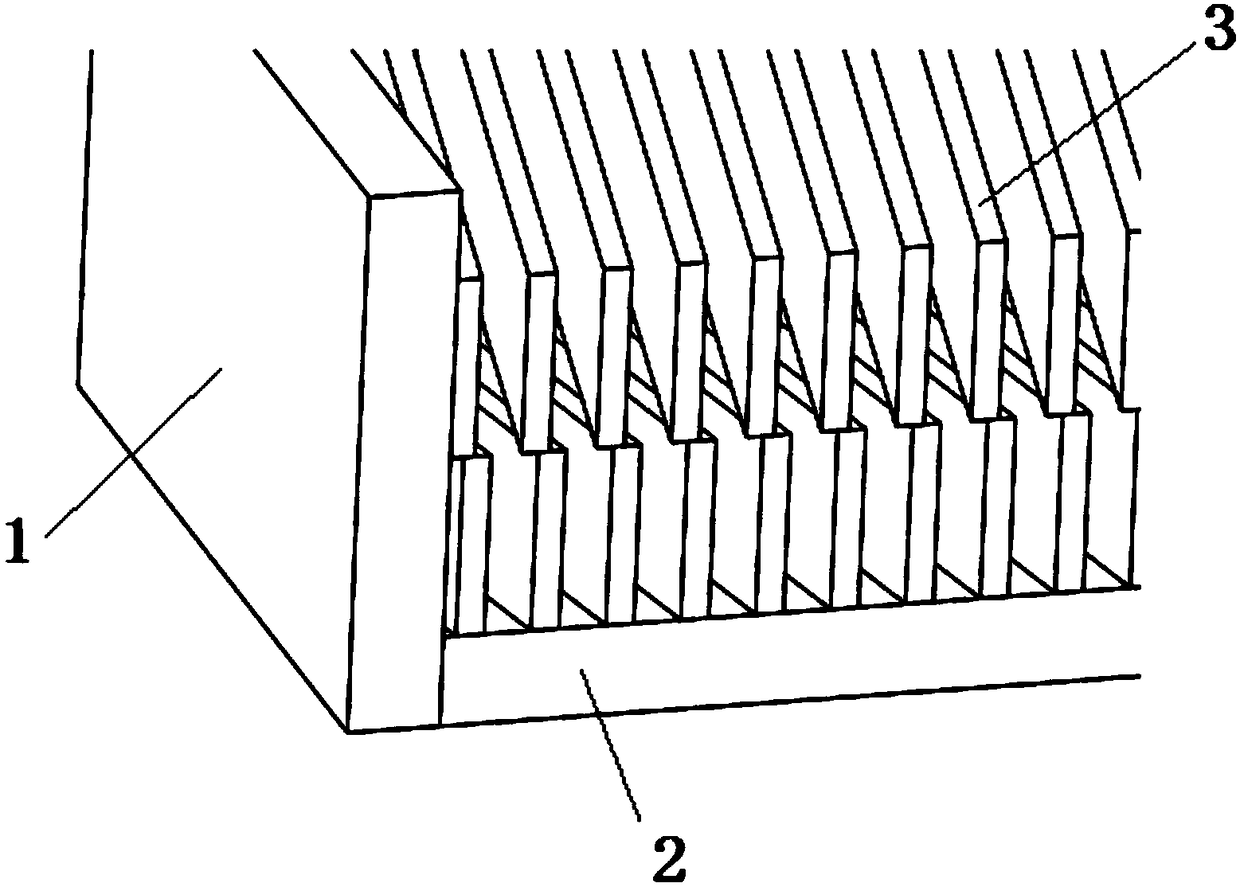

[0026] The present invention is based on the structure of the core body of the bionic linear rib row type micro-staggered alveolar heat exchanger. image 3 As shown, the core body includes a shell 1, and the core body is divided into two layers through the heat exchange plate 2 inside, which are respectively used as medium flow cavities for the flow of cold and hot medium fluids, and heat exchange is performed through the heat exchange plate 2 . There are at least two layers of linear ribs in each cavity. The linear ribs are composed of several linear ribs 3 parallel to each other. Body side walls form a certain staggered angle α, such as Figure 5 ). The linear ribs on two adjacent layers are arranged alternately, that is, there is a certain angle β between the ribs on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com