Micro engine flame tube with internal and external hedging guide vane

A technology of guide vanes and flame tubes, which is applied in the field of micro-engines, can solve the problems of limited improvement of flame surface stability, poor stability, and small range of low-speed areas, etc., and achieve the effects of increased residence time, uniform mixing, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

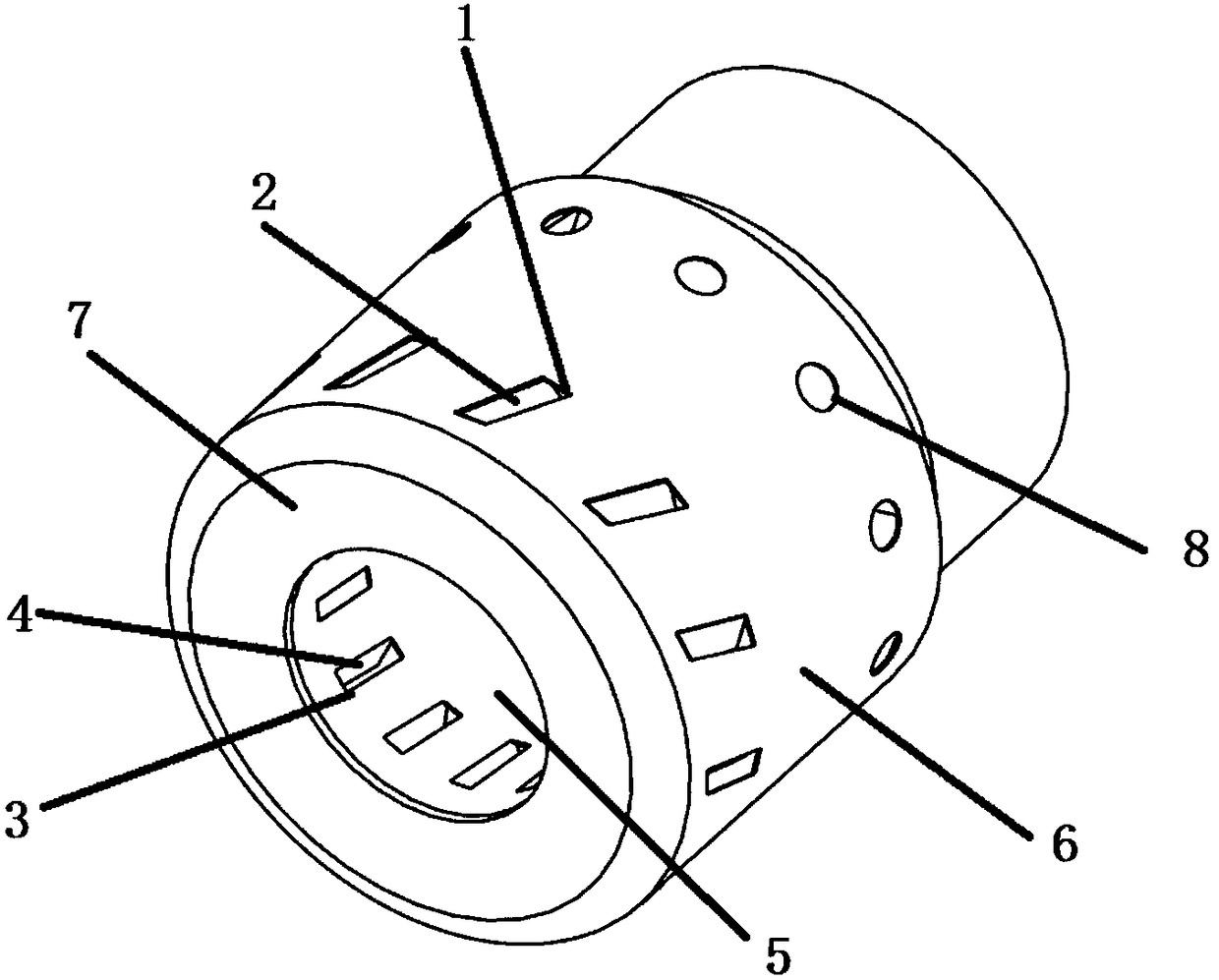

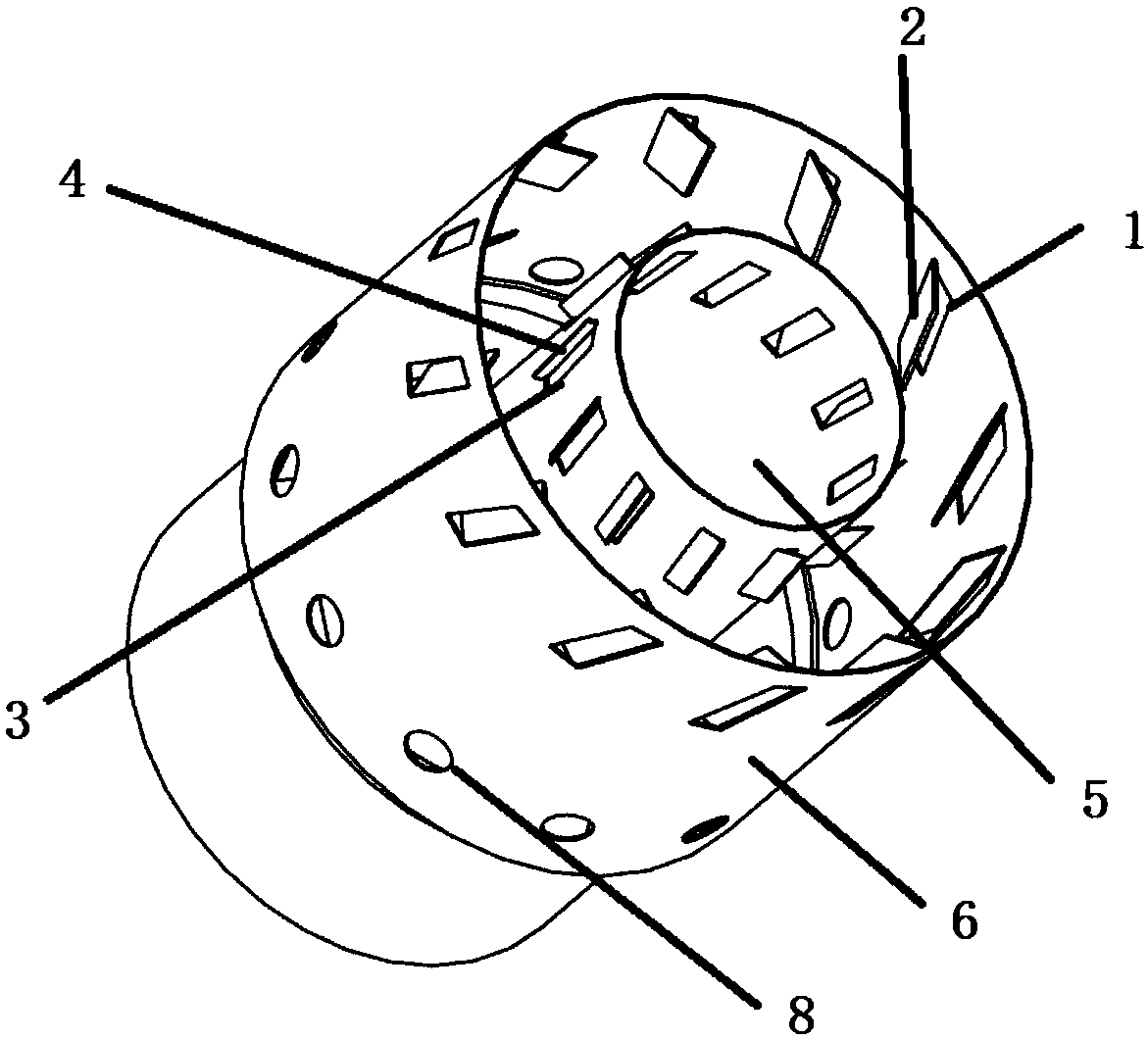

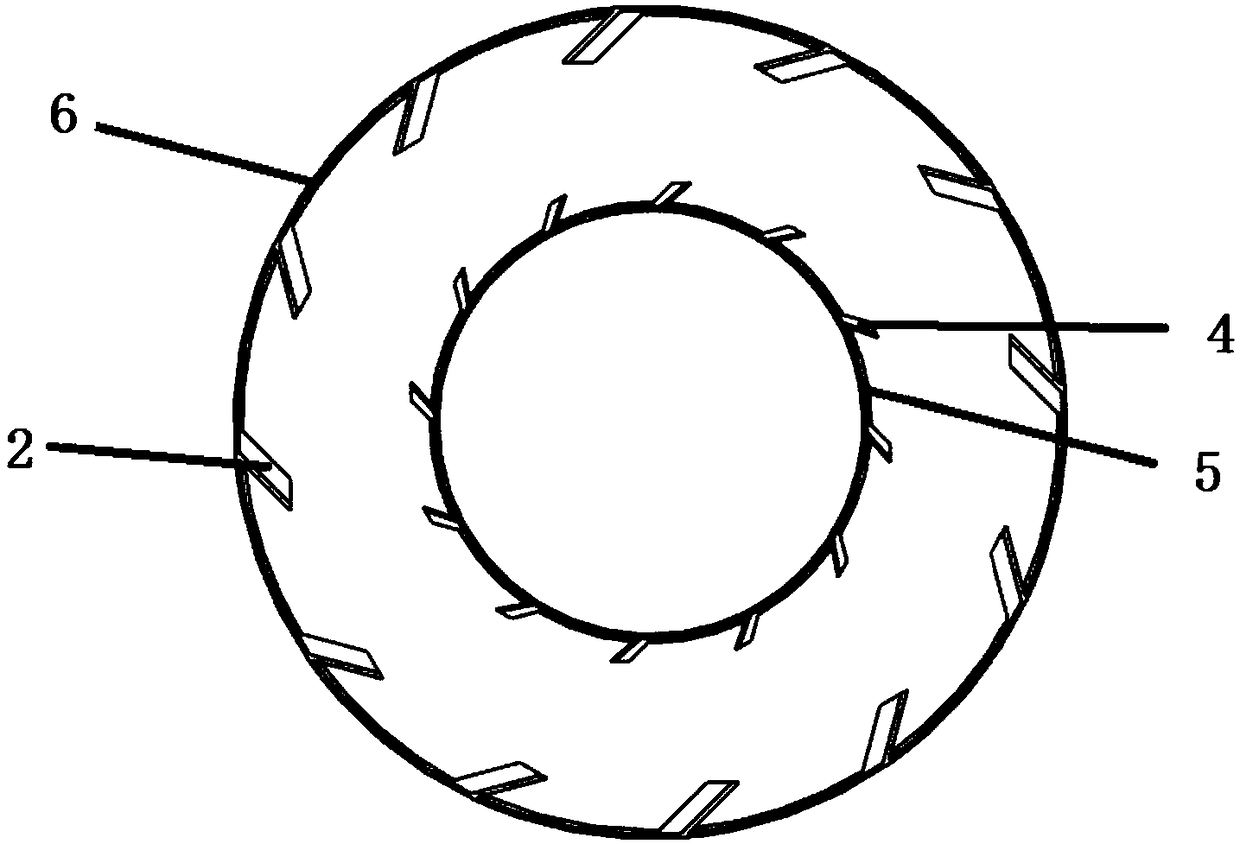

[0021] combine figure 1 , figure 2 , image 3 with Figure 4 , the invention provides a structural design scheme of a micro-engine flame tube with inner and outer opposing guide vanes. figure 1 It is a three-dimensional schematic diagram of a micro-engine flame tube with internal and external opposing guide vanes, figure 2 In order to remove the three-dimensional schematic diagram of the flame tube on the front face, image 3 It is a schematic diagram of the circumferential distribution of the inner and outer opposing guide vanes, Figure 4 It is a cross-sectional view of a micro-engine flame tube with inner and outer opposing guide vanes.

[0022] according to Figure 4 As shown, the present invention rationally designs the main combustion holes of the inner and outer casings of the flame tube and sets up inner and outer counterpoise guide vanes, so that the airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com