Refinement Diagnostics of Solid Fuel Diffusion Combustion Burners

A solid fuel, diffusion combustion technology, used in machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of unthrottled devices, combustion chamber shell ablation, low oxygen utilization rate, etc. The effect of mixing degree, high reuse rate and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

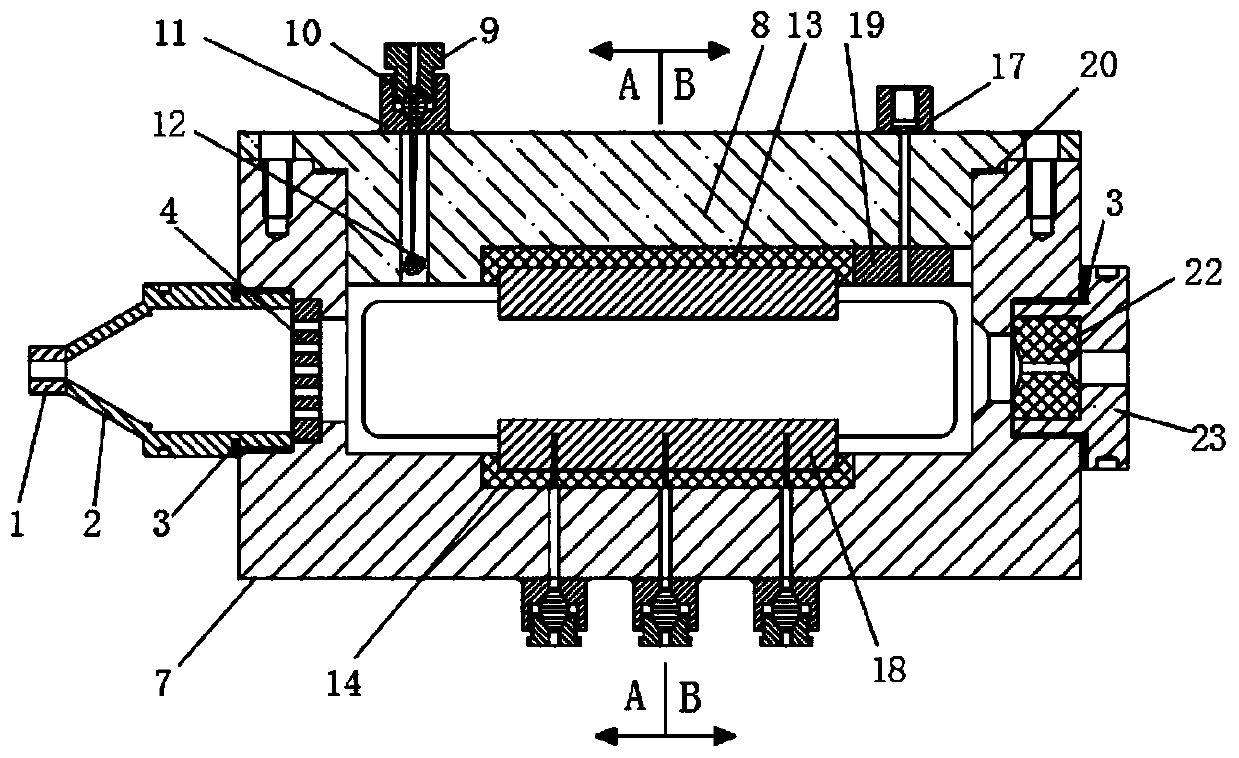

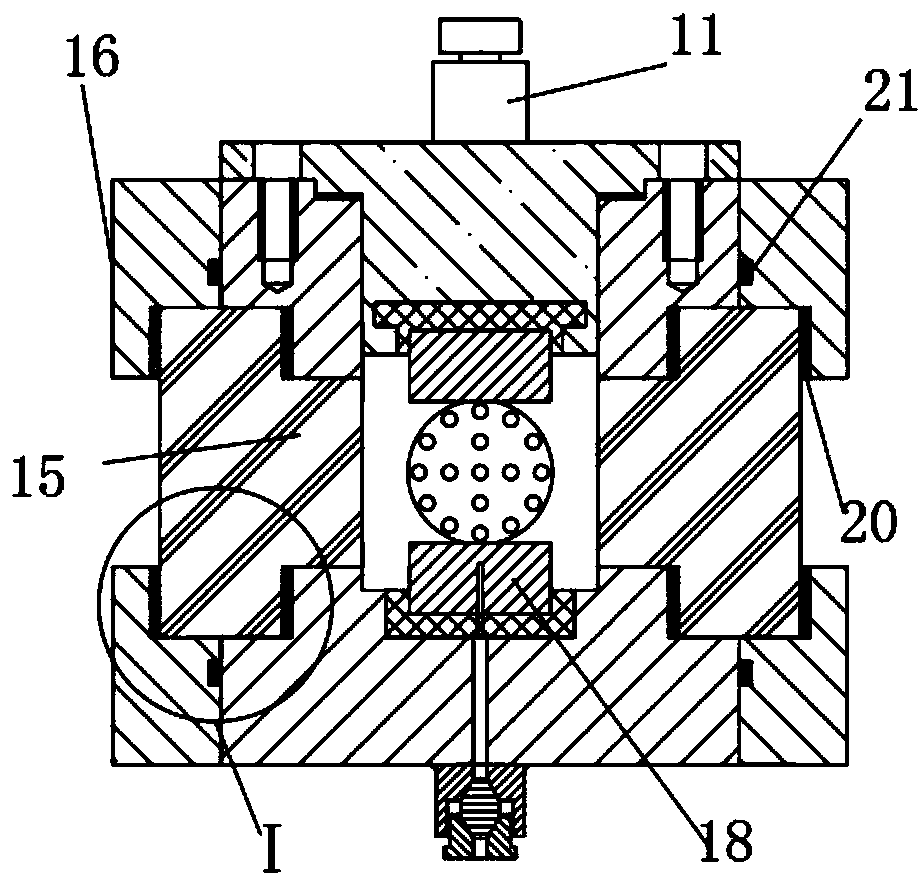

Embodiment 1

[0072] Embodiment 1: When center jet injection is adopted, the injector uses the center jet injector 4, the number of nozzles of the center jet injector 4 is designed to be 17, and the diameter of the nozzle is 3 mm. The fuel is cut into a number of long strips with a length of 20mm×20mm and a length of 60mm. Weigh absolute ethanol and polyvinyl butyral according to the mass fraction of 92% and 8% to configure the coating solution, slowly add polyvinyl butyral to absolute ethanol, place it in a water bath at 50°C, and use a glass rod to Stir continuously until the polyvinyl butyral is completely dissolved, and use the prepared coating solution to evenly coat the side of the solid fuel 18 to ensure that the charges burn in parallel layers. Use a twist drill with a diameter of 0.5mm to drill a hole on one of the solid fuel 18 rods and the graphite insulation layer C 14. The depth of the inner hole of the solid fuel is 2 / 3 of the height of the fuel (so that the solid fuel window ...

Embodiment 2

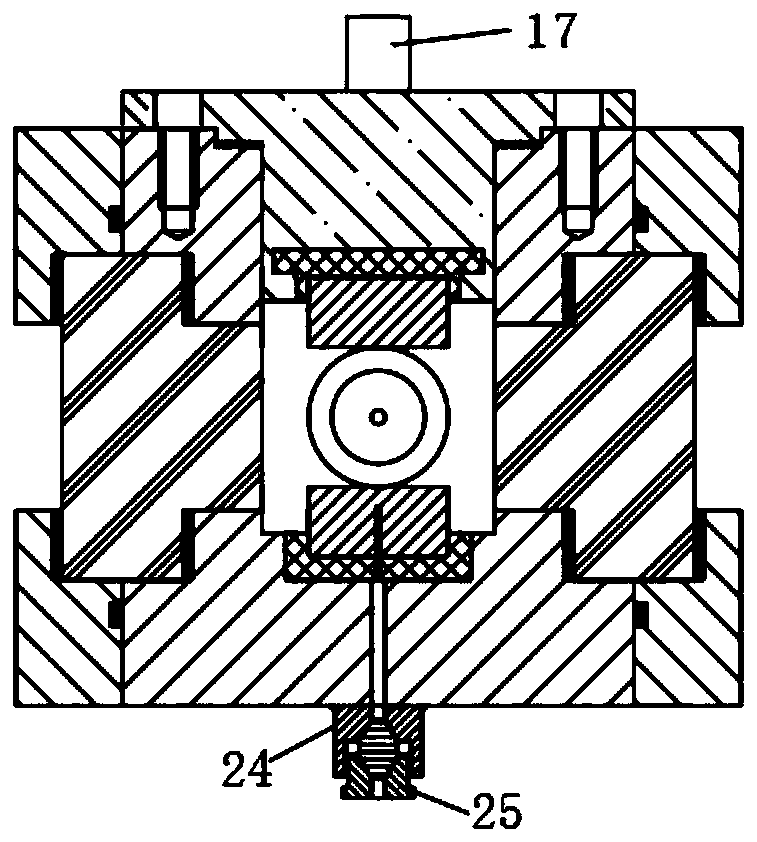

[0074] Embodiment 2: When swirl injection is used, the central jet injector 4 is replaced with a four-corner tangential circle centrifugal injector 5, and the quartz glass 15 is replaced with an arc-shaped quartz glass 26. The four-corner tangential circle centrifugal injector 5 has a tangential air inlet nozzle diameter D=6mm. Trimming the solid fuel 18 grains makes it have a π / 2 arc with the same radius as the curved quartz glass 26 to ensure the swirling environment of the oxidant in the combustion chamber 7 . Weigh absolute ethanol and polyvinyl butyral according to the mass fraction of 92% and 8% to configure the coating solution, slowly add polyvinyl butyral to absolute ethanol, place it in a water bath at 50°C, and use a glass rod to Stir continuously until the polyvinyl butyral is completely dissolved, and use the prepared coating solution to evenly coat the side of the solid fuel 18 to ensure that the charges burn in parallel layers. Use a twist drill bit with a diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com