Countercurrent tangential type micro turbojet engine

A jet engine and micro-turbine technology, applied in the direction of engine components, machines/engines, turbines/propulsion devices, etc., can solve the problems of increasing engine flow resistance, centripetal turbine weight, affecting engine life, etc. Achieve the effects of reducing carbon deposits in the flame tube, increasing working life, and improving fuel combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

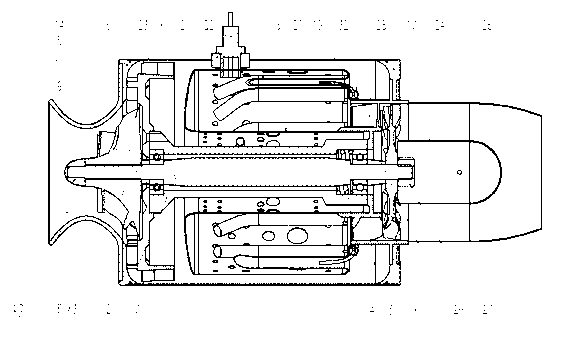

[0020] to combine figure 1 , a counter-flow tangential micro turbojet engine, including a rotor system, a casing, a flame tube, a diffuser 7, a turbine guide 28, a fuel supply system, a lubrication system, a starting gas path 34 and an exhaust system. In terms of the general direction of the entire device, the position of the diffuser 7 is defined as the left end direction of the entire device, and the position of the turbine guide 28 is defined as the right end direction of the entire device. With the rotor system as the center, the diffuser 7 is fixed at the front end of the rotor system, the turbine guide 28 is fixed at the right end of the rotor system, and the exhaust system is located at the right end of the turbine guide 28 . The flame tube is concentric with the rotor system and includes the rotor system. The fuel supply system and the starting gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com