Catalyst anti-wear method for selective catalytic reduction denitration device

A catalyst and selective technology, applied in the fields of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of flow field performance diagnosis and optimization inaccuracy, catalyst wear of reduction and denitrification devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

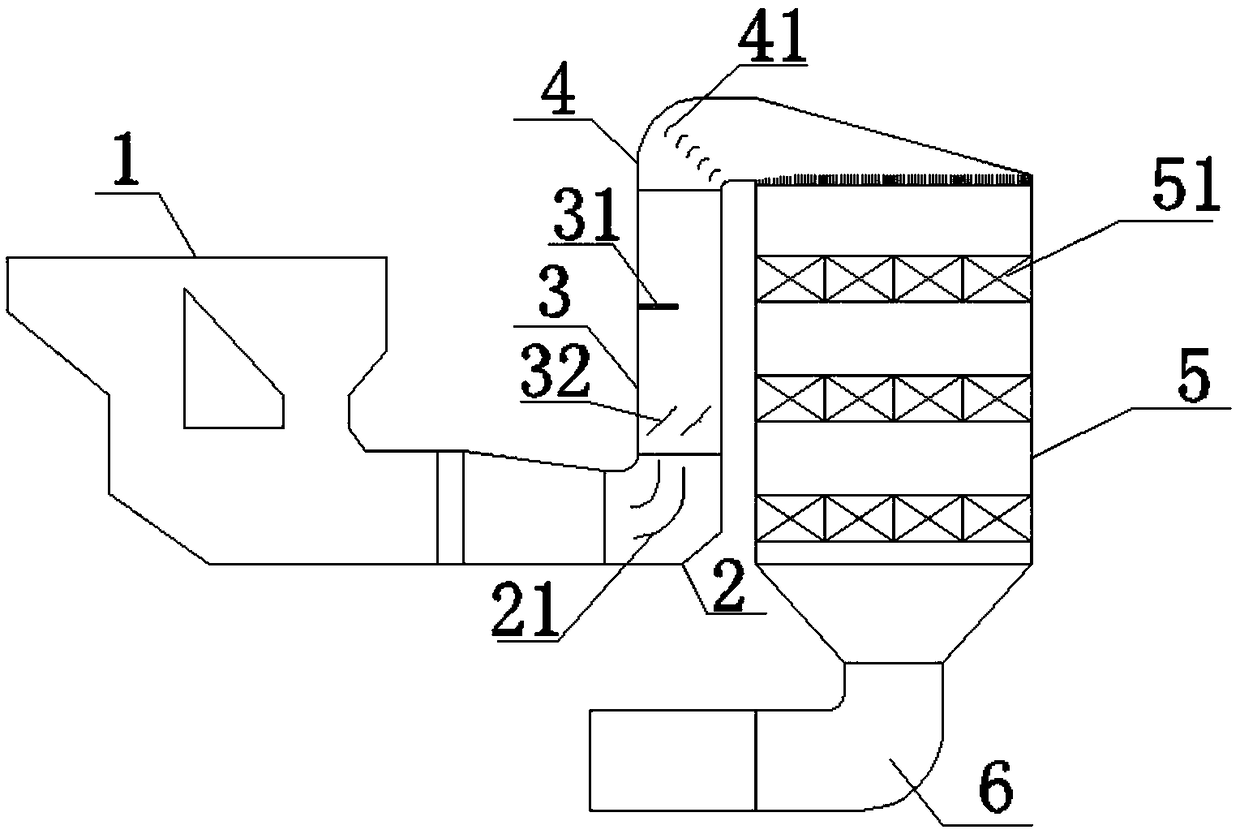

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

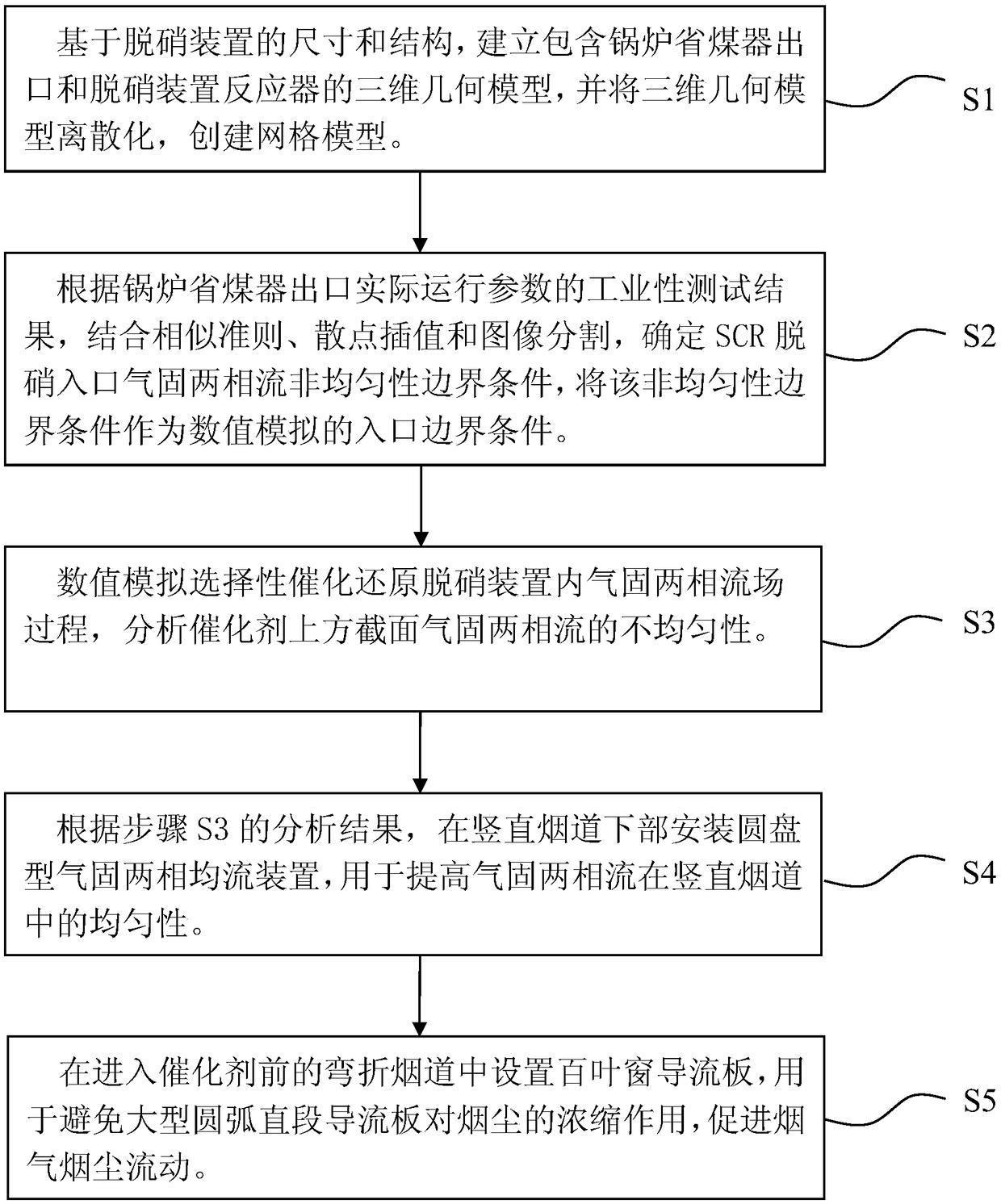

[0026] ginseng figure 1 and figure 2 As shown, this embodiment provides a catalyst wear prevention method for a selective catalytic reduction denitrification device, which includes the following steps:

[0027] Step S1, based on the size and structure of the denitrification device, establish a three-dimensional geometric model including the outlet 1 of the boiler economizer and the reactor of the denitrification device, and discretize the three-dimensional geometric model to create a grid model;

[0028] Step S2, according to the industrial test results of the actual operating parameters of boiler economizer outlet 1, combined with the similarity criterion, scatter inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com