Homodromous reverse spiral mixing device

A helical mixing and helical technology, which is used in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of fluid mixing uniformity that does not meet application requirements, unsatisfactory mixing effect, and low mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

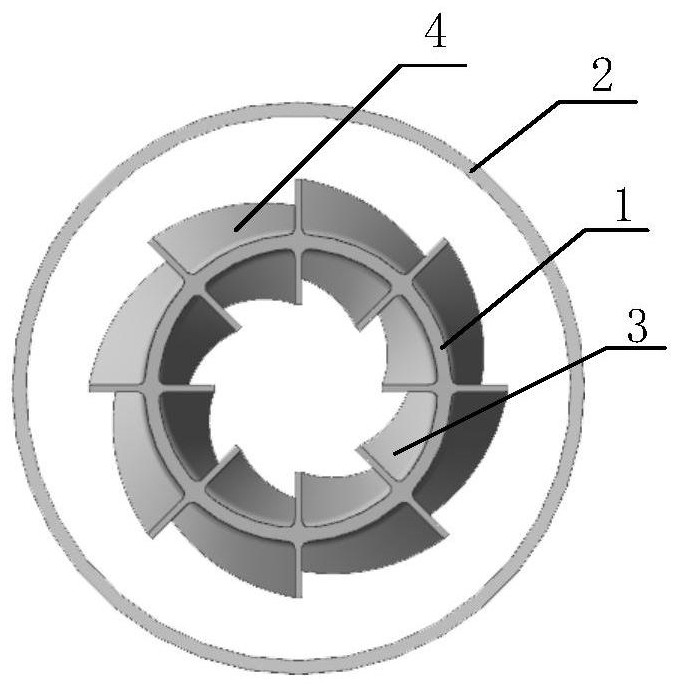

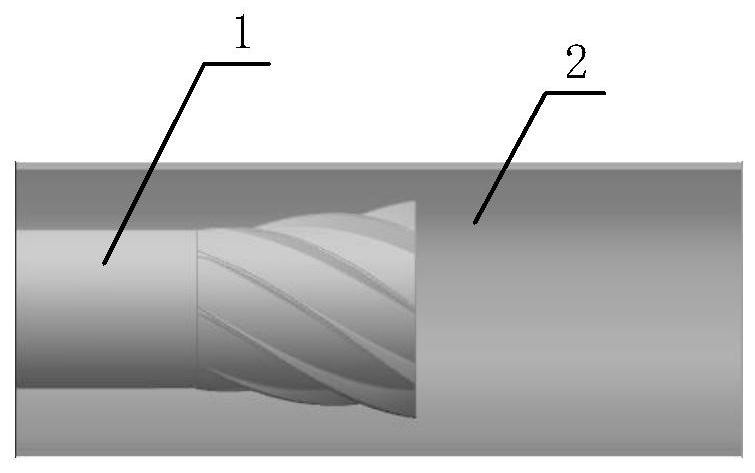

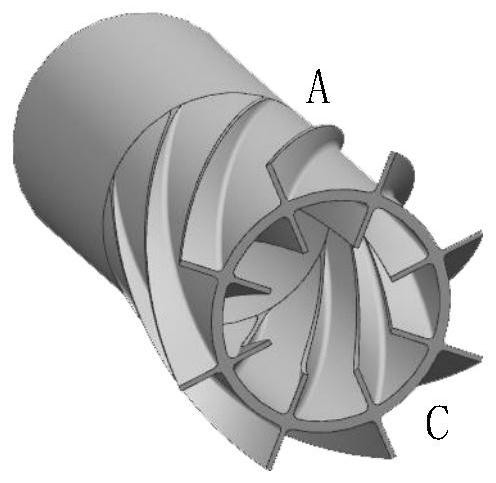

[0024] A circular fluid pipeline 1 is placed inside another circular fluid pipeline 2, the outlet C of the inner fluid pipeline 1 is located inside the outer fluid pipeline 2, and there are 8 inner fluid pipeline 1 outlet section AC The spiral direction of the gradually rising spiral deflector 3 is along the direction of the internal fluid outlet (right-hand rule), and the outer side of the outlet section AC of the internal fluid pipeline 1 is arranged with 8 gradually rising spiral deflectors 3 opposite to the spiral direction of the inner spiral deflector 3. High reverse spiral deflector4.

[0025] When the two fluids flowing through pipeline 1 and pipeline 2 respectively flow in the same direction, under the action of the inner helical deflector 3, the fluid injected from pipeline 1 forms a clockwise swirl flow when viewed in the direction of flow; Under the action of the deflector 4, the fluid ejected from the pipeline 2 forms a swirling flow counterclockwise when viewed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com