Jack dynamic testing system

A dynamic test and jacking technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as low safety performance, achieve good practical performance, reduce work intensity, and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

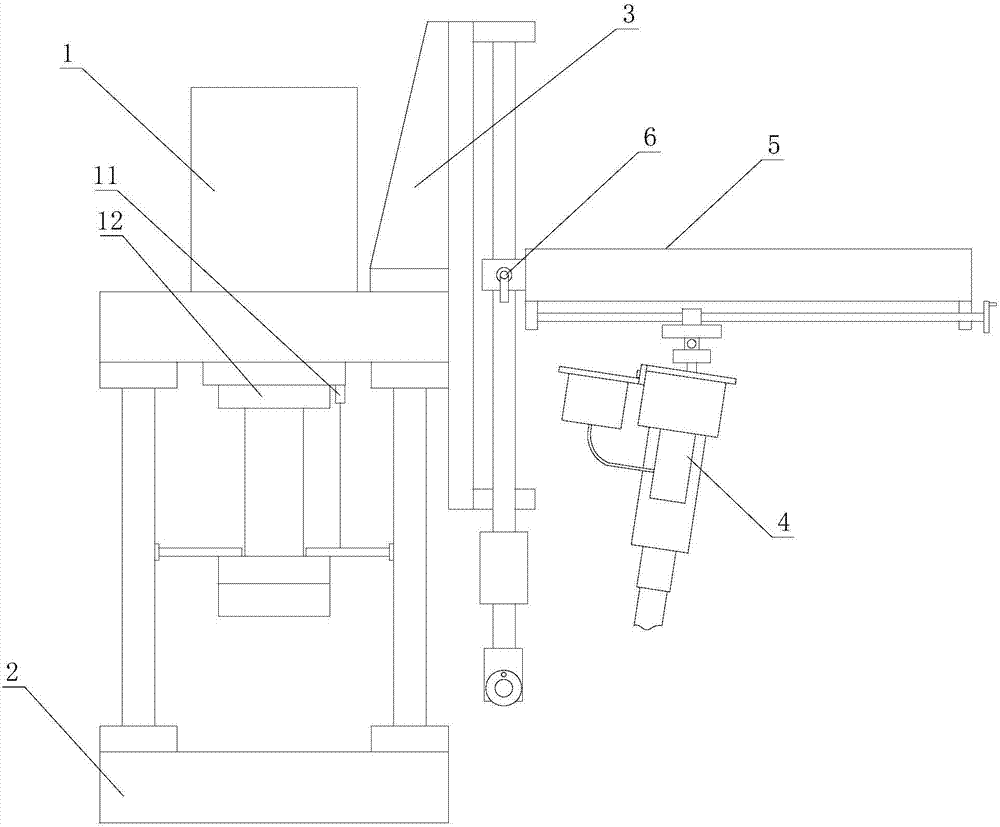

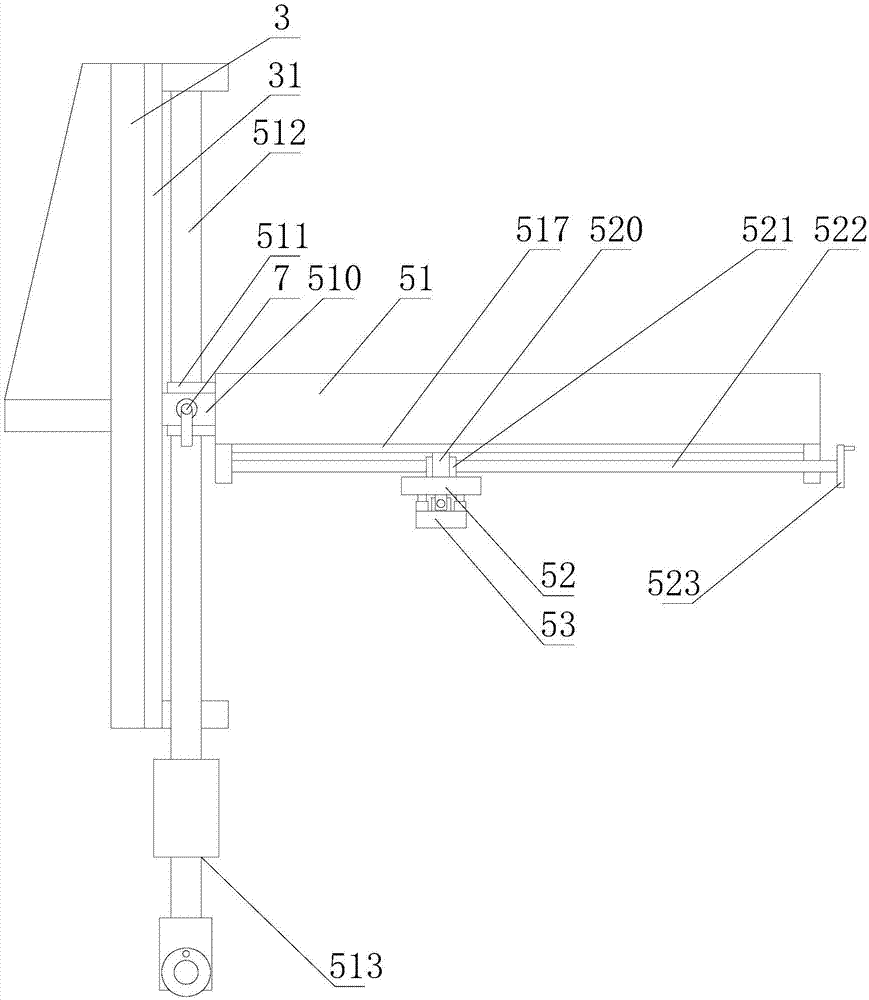

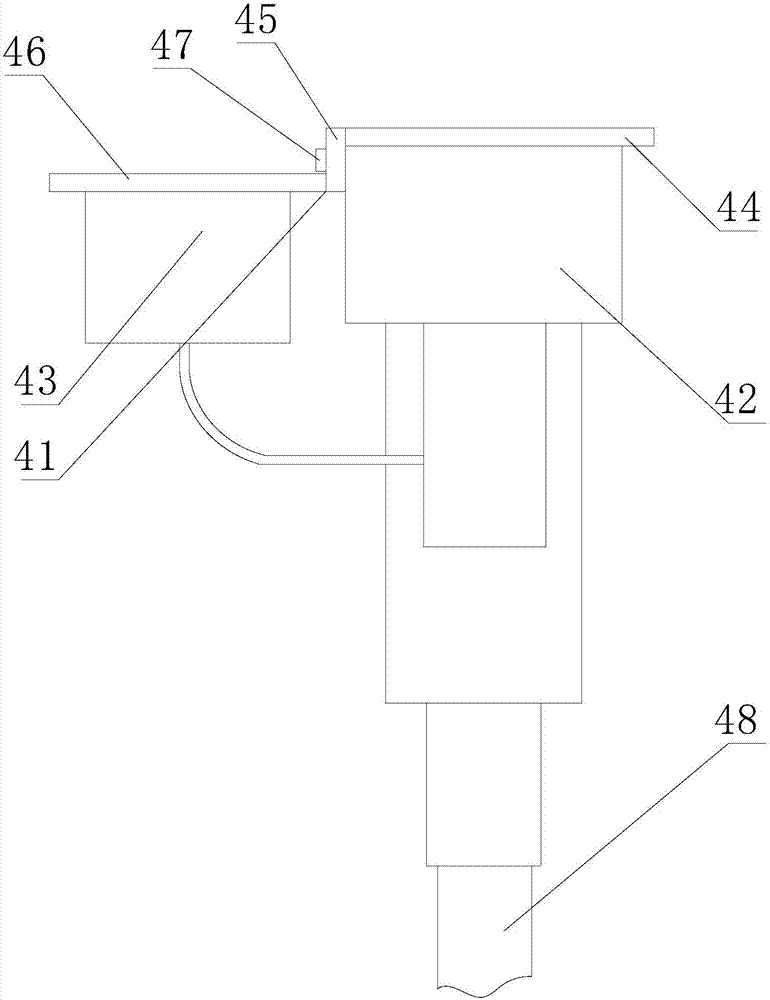

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11As shown, the jack dynamic test system includes a hydraulic constant pressure system 1 and a test bench 2 for placing the jack to be tested. The hydraulic constant pressure system 1 is set above the test bench 2, and the hydraulic constant pressure system 1 is provided with a pressure sensor. 11 and a displacement sensor 12, the pressure sensor 11 is facing the test bench 2, and also includes a connecting bracket 3 and an operating arm 4 that automatically applies an operating force to the jack. The operating arm 4 is detachably connected to the jack handle, and the connecting bracket 3 is arranged on the On the constant pressure system 1 , the connecting bracket 3 is provided with an adjusting device 5 for adjusting the applied angle of the operating arm 4 , and the adjusting device 5 is provided with a self-locking device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com