Low-air-pressure ejector device applied to mars wind tunnel

An ejector and low air pressure technology, which is applied in the direction of measuring devices, instruments, jet pumps, etc., can solve the problems of easy freezing of jet air, low gas density, and large gas consumption, so as to increase the highest wind speed and high ejection efficiency , The effect of small gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

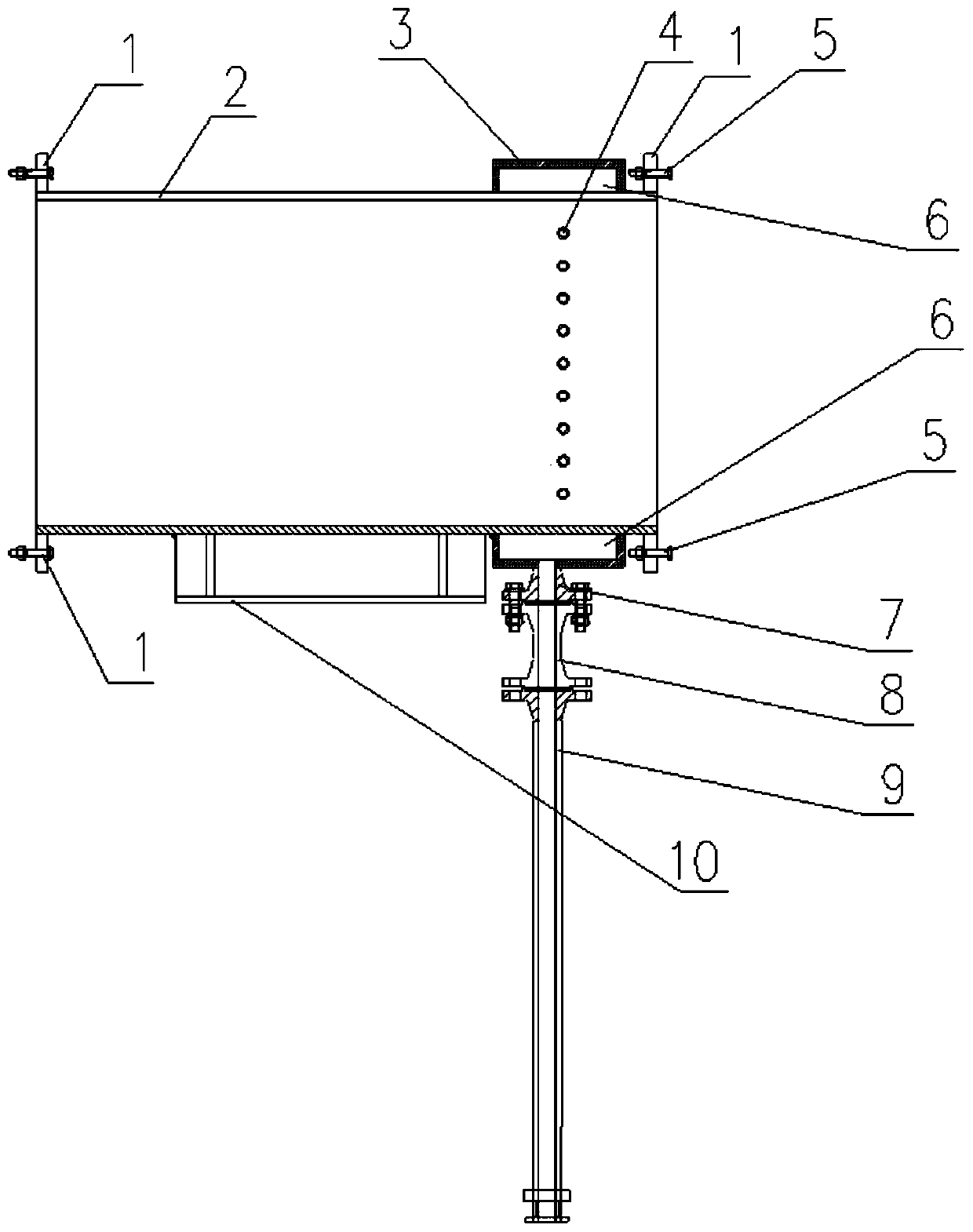

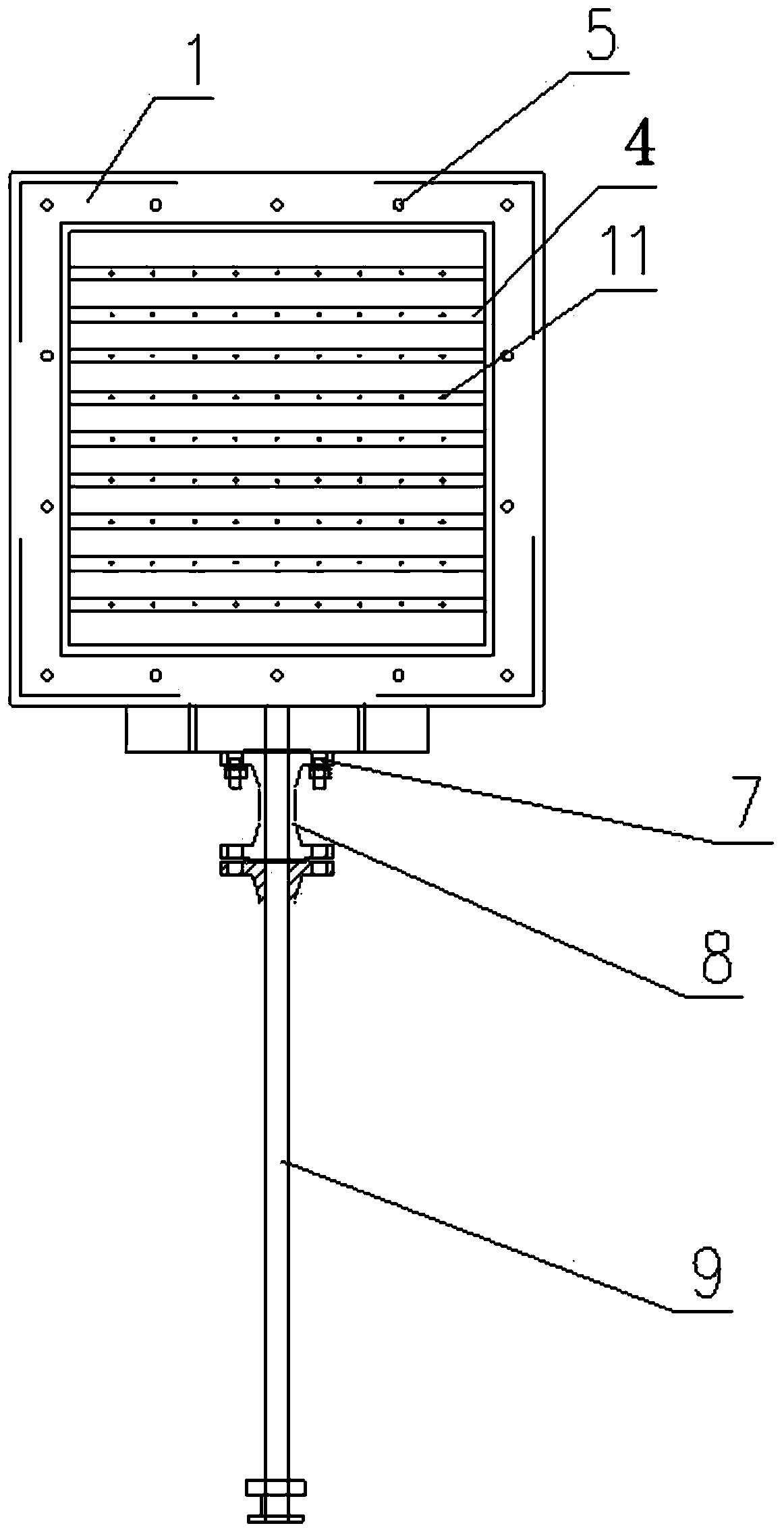

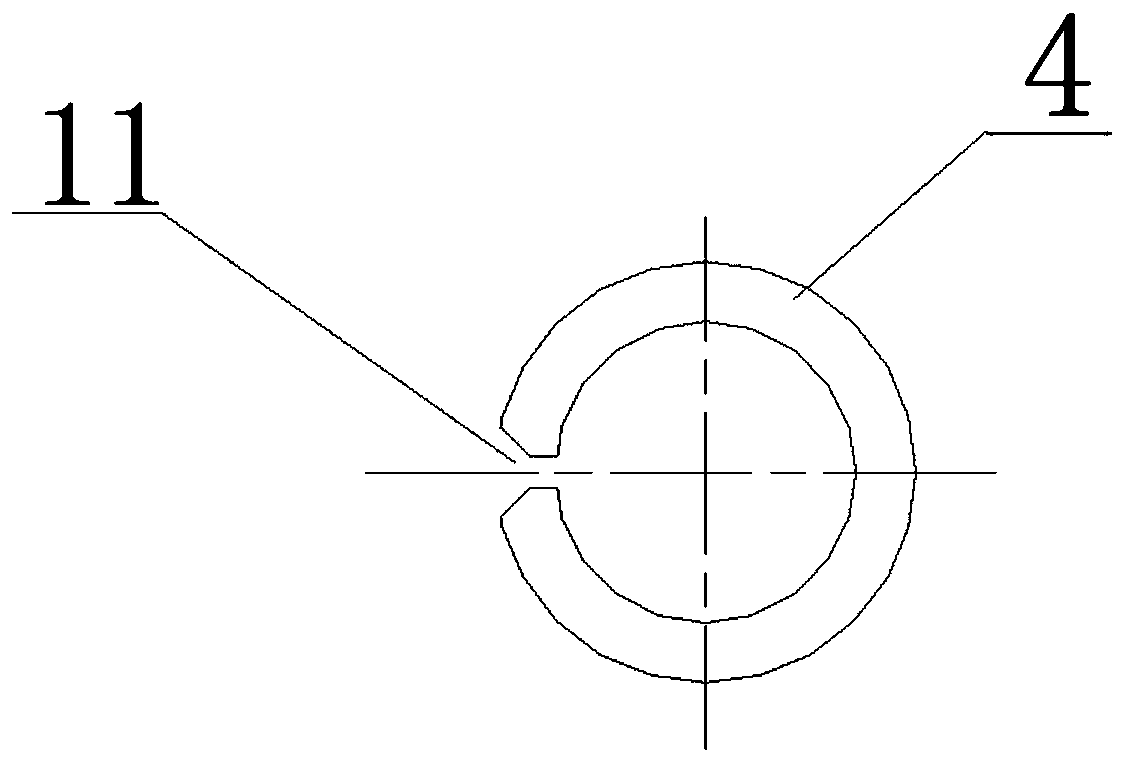

[0021] Such as Figure 1-4 As shown, a low-pressure ejector device applied to a Mars wind tunnel includes an ejector housing 2, an ejector chamber shell 3, an ejector chamber 6, a plurality of nozzle pipes 4 and an air supply pipeline 9. The gas supply line 9 is in communication with the gas source. The ejector chamber casing 3 surrounds the ejector housing 2 and is sealed and connected to its outer wall to form a closed ejector chamber 6. The air supply line 9 It communicates with the ejector chamber 6, and a plurality of nozzle pipes 4 are parallel to each other and radially pass through the ejector housing 2 at a certain interval. The head and tail of each nozzle pipe 4 are connected to the ejector chamber respectively. 6, and each nozzle 4 is provided with a plurality of nozzles 11 on the part inside the ejector housing 2. The nozzle 11 is a conical throat hole with a straight pipe. The throat hole adopts a 45-degree diffusion method, which can obtain high wind speed unde...

Embodiment 2

[0023] combine Figure 4 , a low-pressure ejector device applied to a Mars wind tunnel, comprising an ejector housing 2, an ejector chamber shell 3, an ejector chamber 6, a plurality of nozzle pipes 4 and an air supply pipeline 9, The gas supply pipeline 9 communicates with the gas source. The ejector chamber casing 3 surrounds the ejector housing 2 and is sealed and connected to its outer wall to form a closed ejector chamber 6. The gas supply pipeline 9 is connected to the ejector chamber. The ejector chamber 6 communicates, and a plurality of nozzle pipes 4 are parallel to each other and radially pass through the ejector housing 2 at a certain interval. The head and tail of each nozzle pipe 4 communicate with the ejector chamber 6 respectively. A plurality of nozzles 11 are opened on the part of each nozzle pipe 4 located inside the ejector housing 2 . The gas source of the ejector device is stored in the buffer tank and introduced through the intake pipe 19, CO 2 The gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com