Backflow type wind tunnel device for simulating Mars low-pressure low-density dust storm environment

A low-density, low-pressure technology, applied in the field of deep space exploration space environment ground simulation, can solve the problems of low vacuum pumping cost, high economic cost, small size, etc., achieve high economy, improve ejection efficiency, and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

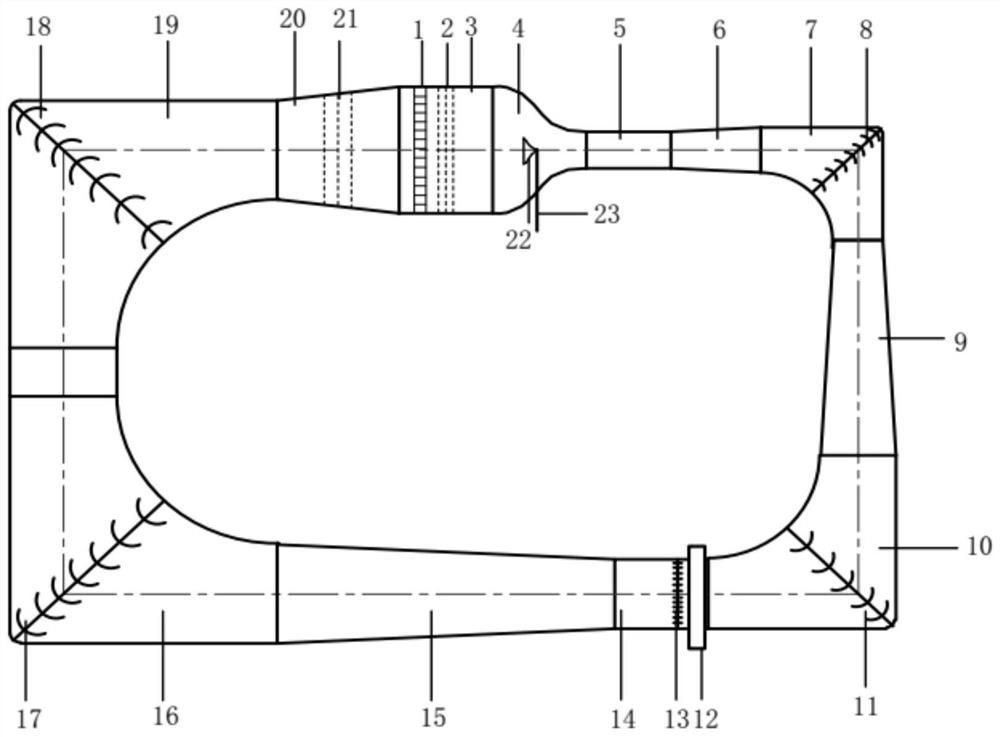

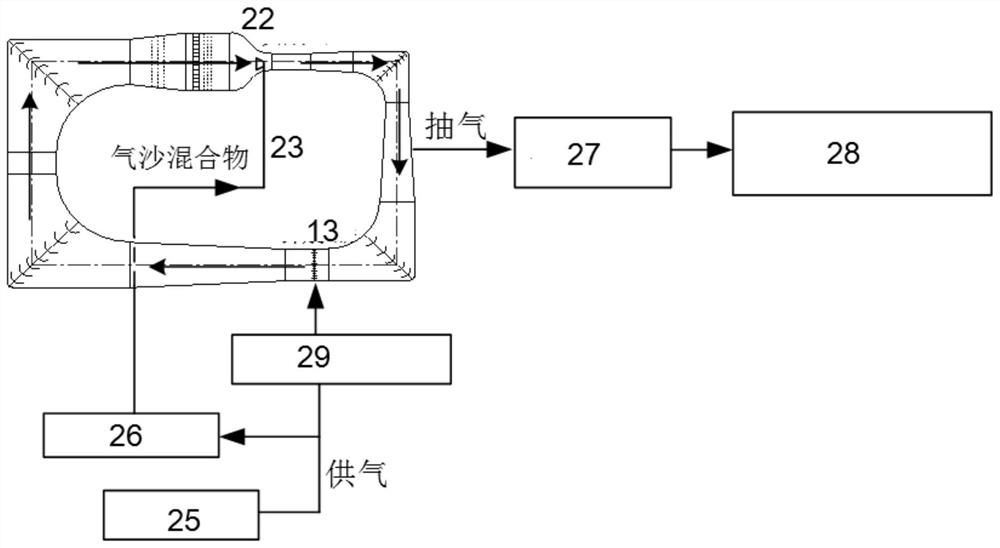

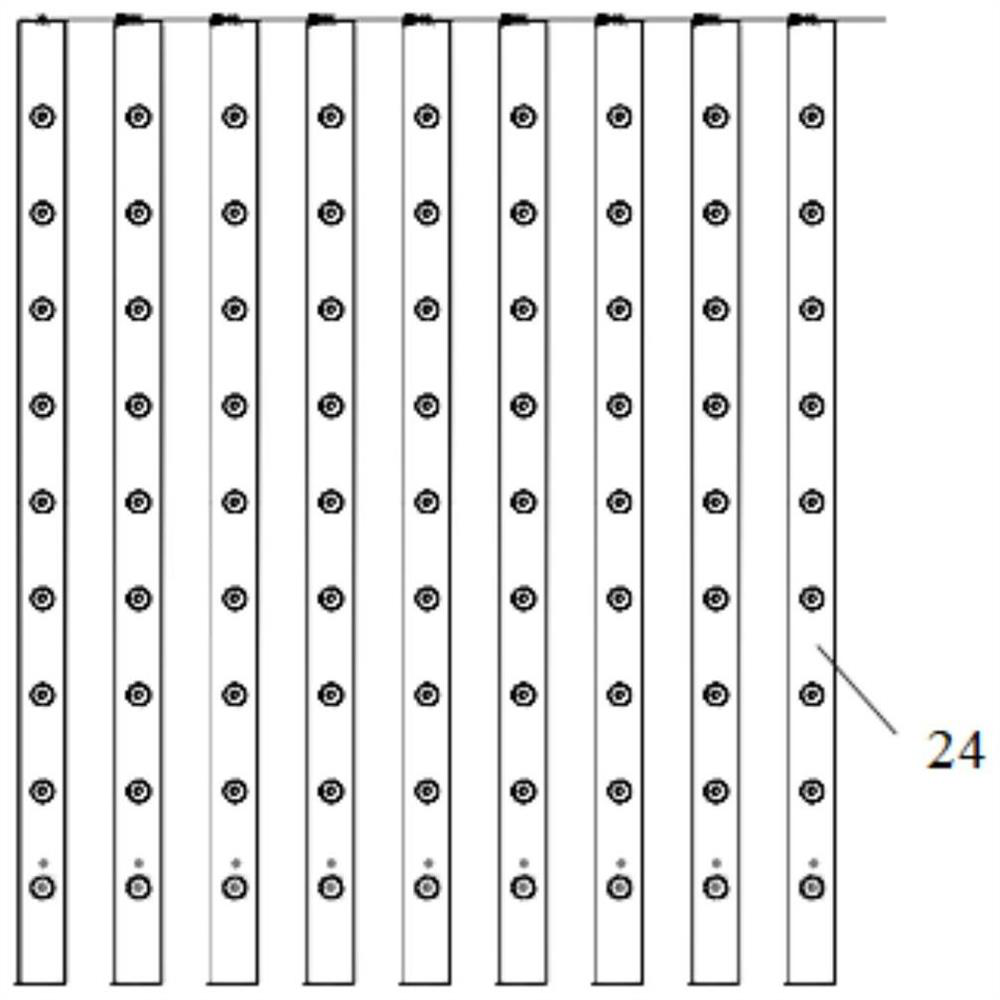

[0025] Such as Figure 1-Figure 3 As shown, a return-type wind tunnel device for simulating the low-pressure and low-density dust storm environment on Mars includes a return-type wind tunnel, an ejector 13 and an injector 22. The described return-type wind tunnel includes successively connected stable sections 3, shrink Section 4, test section 5, first diffuser section 6, second diffuser section 9, mixing section 14, third diffuser section 15 and large-angle diffuser section 20, between the first diffuser section 6 and the second diffuser section The first corner 7 is communicated between the pressure sections 9, the second corner 10 is communicated between the second diffuser section 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com