Ejecting pipe

An ejector tube and cross-section technology, applied in the ejector tube field, can solve the problems of uneven flame length, influence the primary air coefficient, influence the ejection efficiency, etc. The effect of shooting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

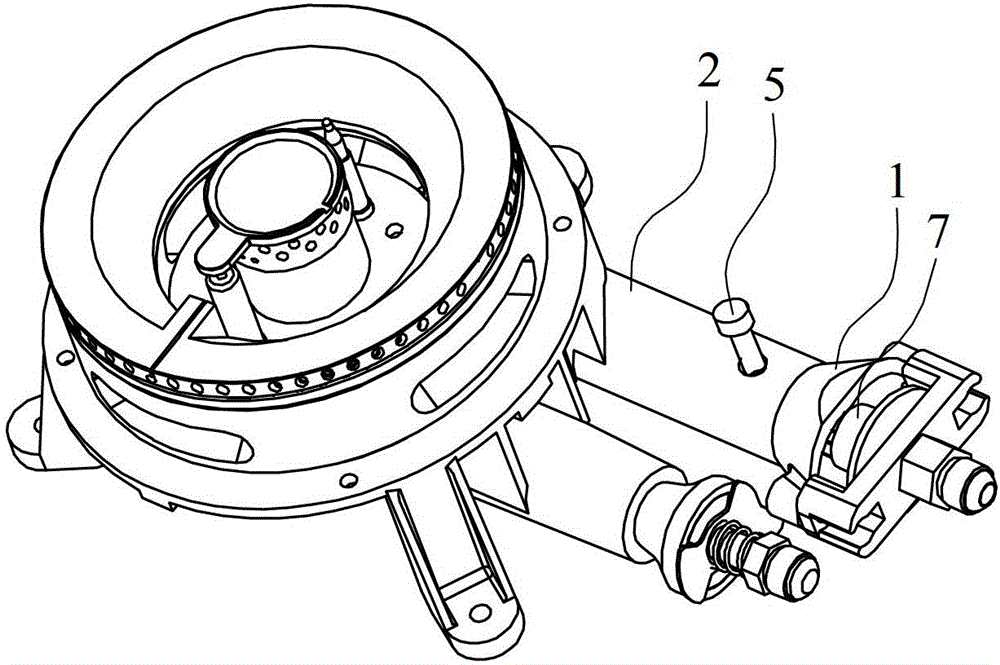

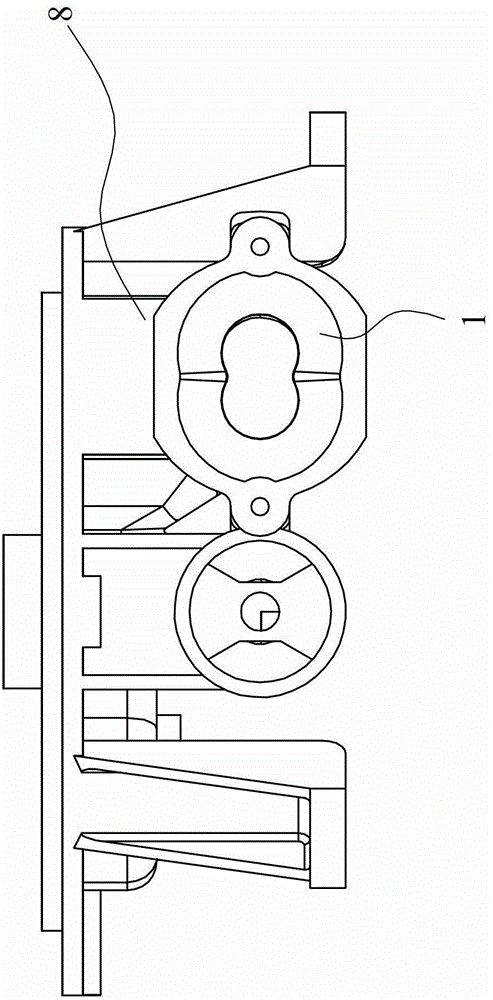

[0024] Such as Figure 1~6 As shown, the ejector tube in embodiment 1, its inner cavity is along the direction from the inlet to the outlet, followed by the horn section 1, the transition section 2 and the tail interface 3 that is compatible with the burner burner 8, and the horn section 1 and the A mouth 6 is formed between the transition sections 2, wherein a hole 9 is radially penetrated in the pipe wall of the transition section 2 close to the mouth 6, and a bolt 5 is internally threaded in the hole 9, so that the bolt 5 can move up and down by turning the thread To change the cross-sectional area of the transition section 2 where it is located, to block the ejection flow, thereby changing the ejection coefficient.

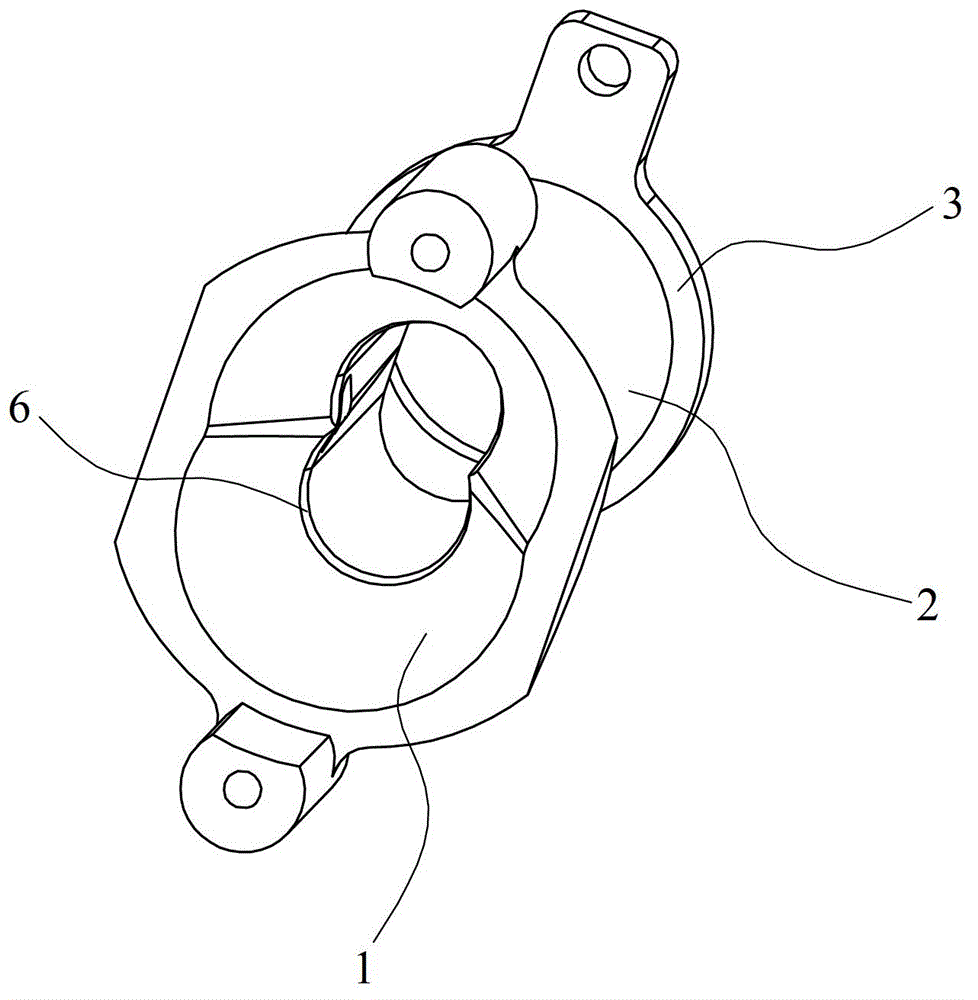

[0025] The outer contour of the cross section of the horn section 1 (that is, the cross section of the cavity surrounded by the horn section) is formed by the intersection of two circles, the centers of the two circles are located on the same first circle, a...

Embodiment 2

[0028] Such as Figure 7 As shown, the difference between the ejector tube in embodiment 2 and embodiment 1 is that the outer contour of the horn section 1 is formed by the intersection of three circles, the centers of the three circles are located on the same first circle, and relative to the The center of the first circle is evenly distributed, the radius r of the circle is 5, the radius R of the first circle is 4, and the nozzles matched with the injection tube are set at the centers of the three circles, that is, the nozzles matched with the injection tube The number of nozzles is three. Compared with the single-nozzle injection pipe, the three-nozzle injection pipe can enhance the ejection ability of the injection pipe, and can inhale more air, which improves the primary efficiency of the burner with this injection pipe. air supply.

[0029] It can be seen from the above description that the cross-section of the horn section 1 is plum-shaped and gradually becomes smaller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com