Method and device for mechanically pressurizing, injecting and recovering waste steam for suction section

A waste steam and ejector technology, applied in mechanical equipment, jet pumps, machines/engines, etc., can solve the problem of low ejection coefficient, and achieve the effect of high energy recovery rate, simple equipment and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

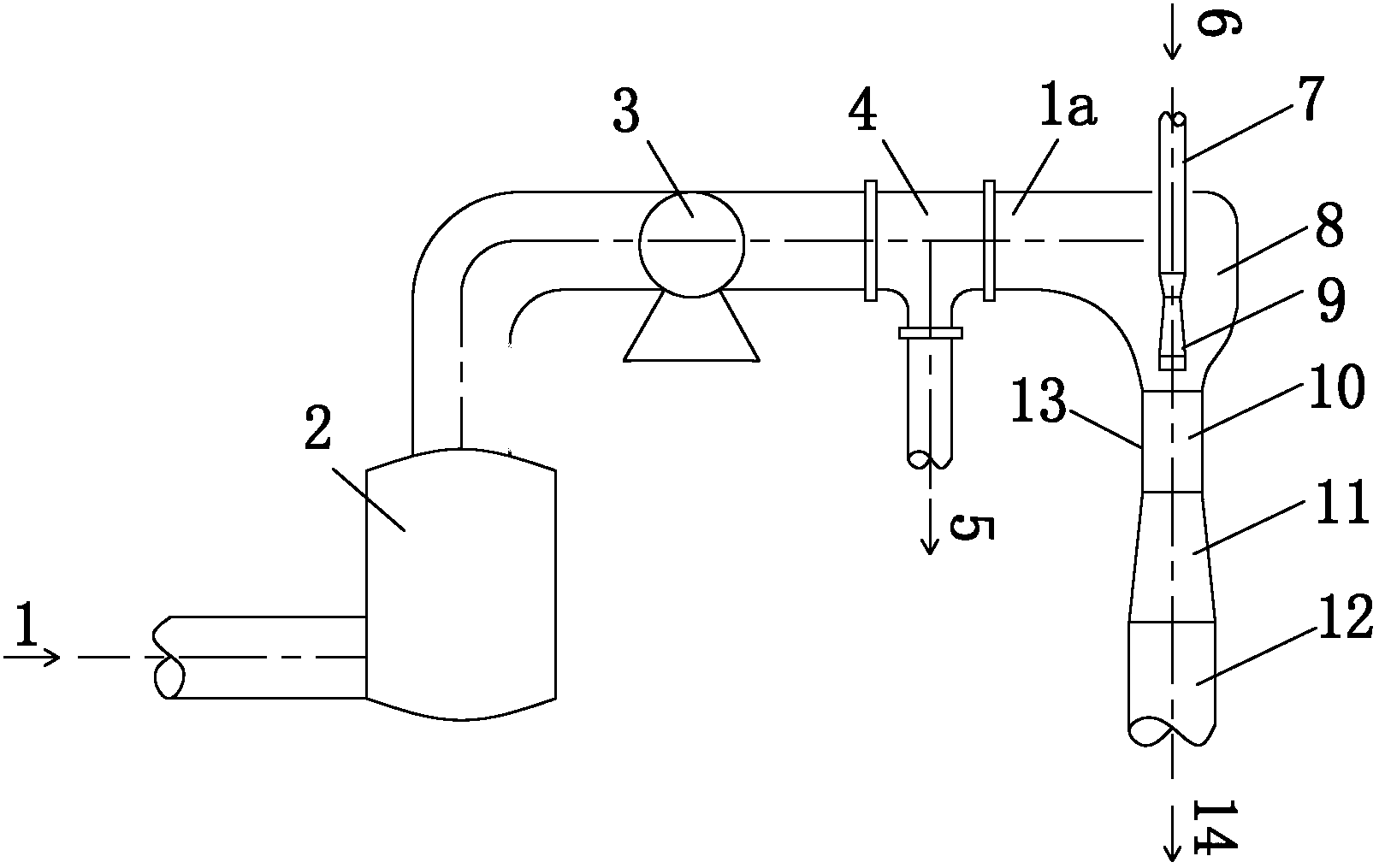

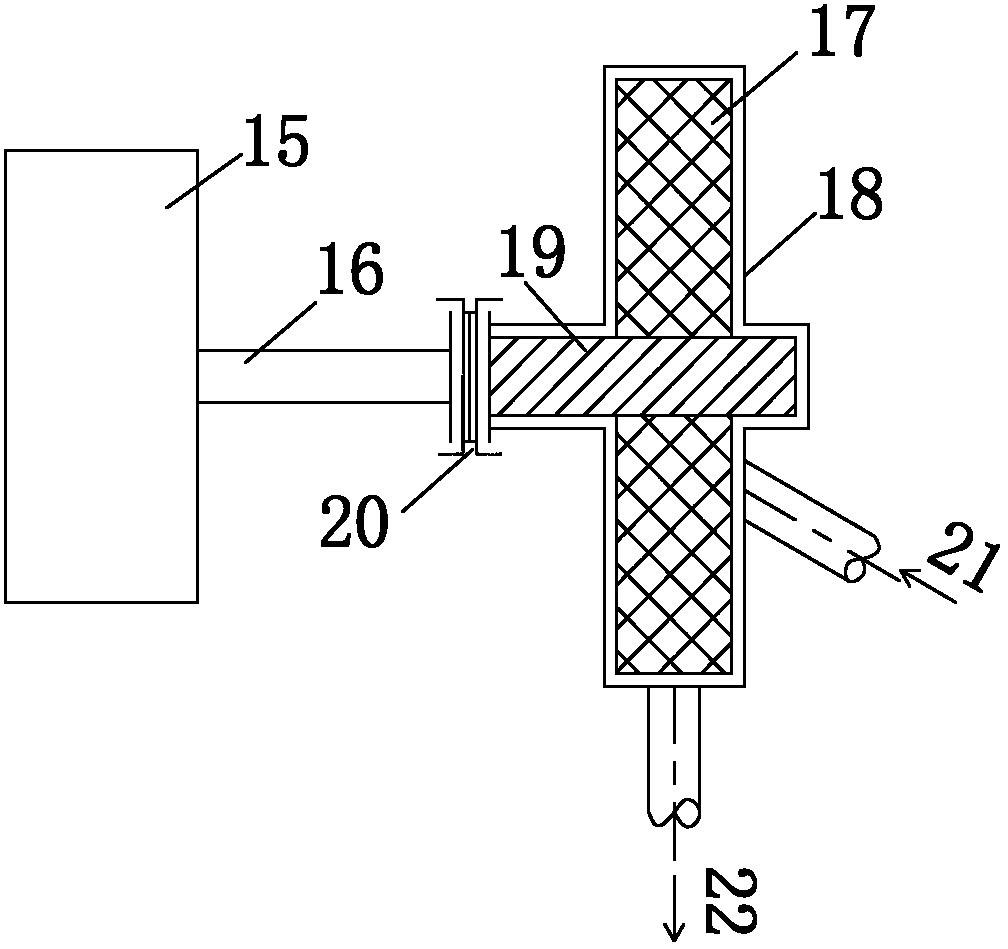

[0027] Mechanically pressurized steam ejectors are used to recover waste steam, such as figure 1 shown. The waste steam 1 from the production process enters the heating device 2 for heating to form supersaturated waste steam, and then enters the pressurizer 3 to be pressurized and then sent to the vapor-liquid separator 4 to discharge the possible condensed water 5 and send the pressurized steam into the Ejector 13. Wherein pressurizing machine 3 structures such as figure 2 As shown, the pressing machine casing 18 isolates the pressing machine rotating shaft 19 from the outside, so that the pressing machine rotating shaft 19 and the rotating shaft 16 of the motor 15 form two independent shafts respectively, and the motor and the pressing machine are arranged therebetween. Magnetically conductive connection 20 of the rotating shaft. The rotational power of the rotating shaft of the motor at the connecting piece is transmitted to the rotating shaft of the pressing machine th...

Embodiment 2

[0029] The device for recovering waste steam by mechanically pressurized water ejector such as figure 1shown. The waste steam 1 from the production process enters the heating device 2 for heating to form supersaturated waste steam, enters the pressurizer 3 and is pressurized, and is directly sent to the ejector 13 without passing through the vapor-liquid separator. The pressurized water 6 is sent into the nozzle 9 by the working water inlet 7 . When the nozzle outlet reaches a very high speed, most of the pressure potential energy is converted into kinetic energy, so that the pressure of the pressurized water is reduced below the pressure of the pressurized ejection steam, forming a local relative negative pressure, and the pressurized waste steam is ejected to the Reception room 8. Further enter the mixing chamber 10 to fully mix and balance the speed and energy. At the outlet section of the mixing chamber 10, a uniform velocity field and energy field are established to for...

Embodiment 3

[0031] The application example of using steam as the working fluid to eject the waste steam mechanically pressurized ejector is the same as that of Example 1, the difference is that no vapor-liquid separator is installed after the pressurizer, and the waste steam is heated to the heating device 2 It is realized by adding a small amount of working steam to the inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com