Burner for gas stove

A technology of gas stoves and burners, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of small heat load, high cost, incomplete gas, etc., and achieve reduced overall height, compact structure, and stable flames Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

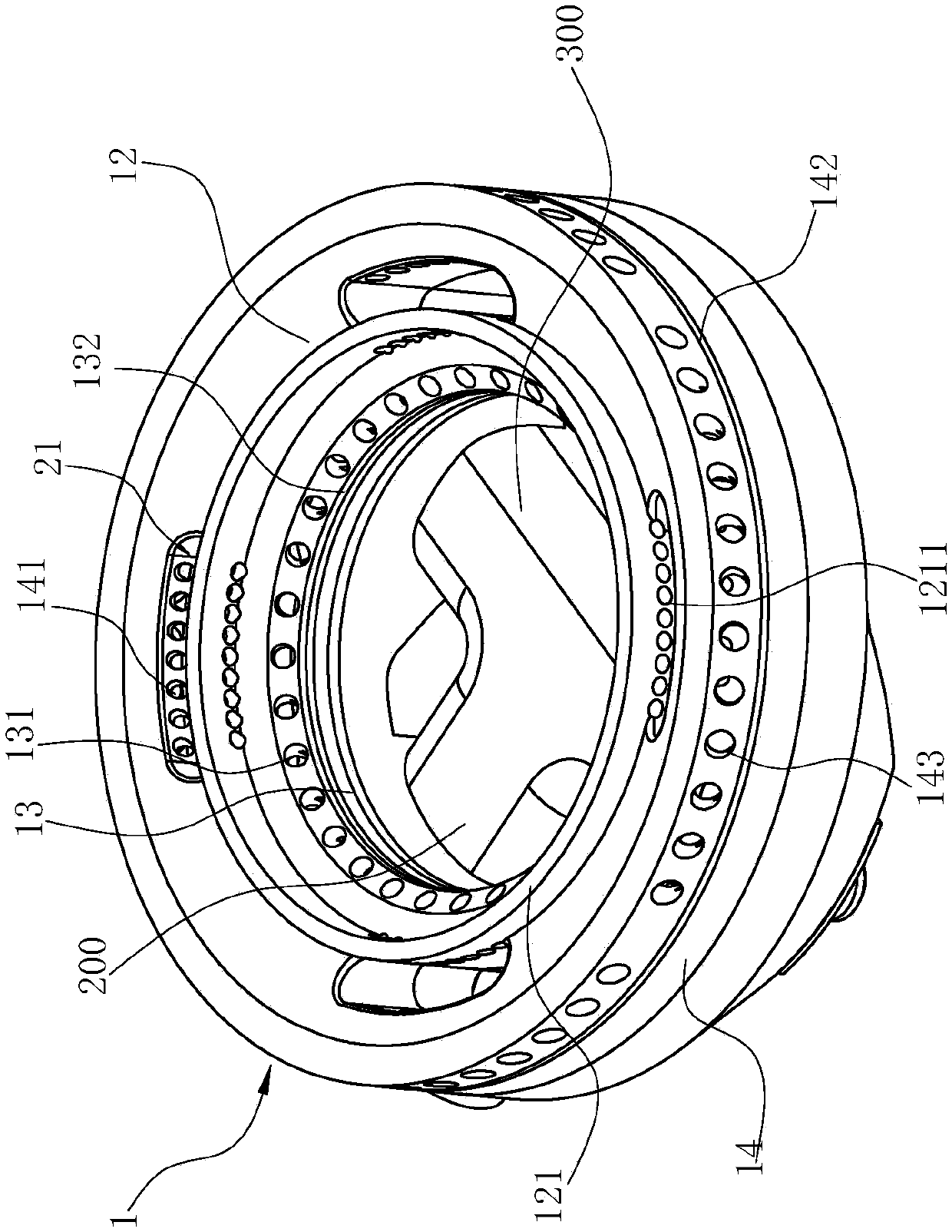

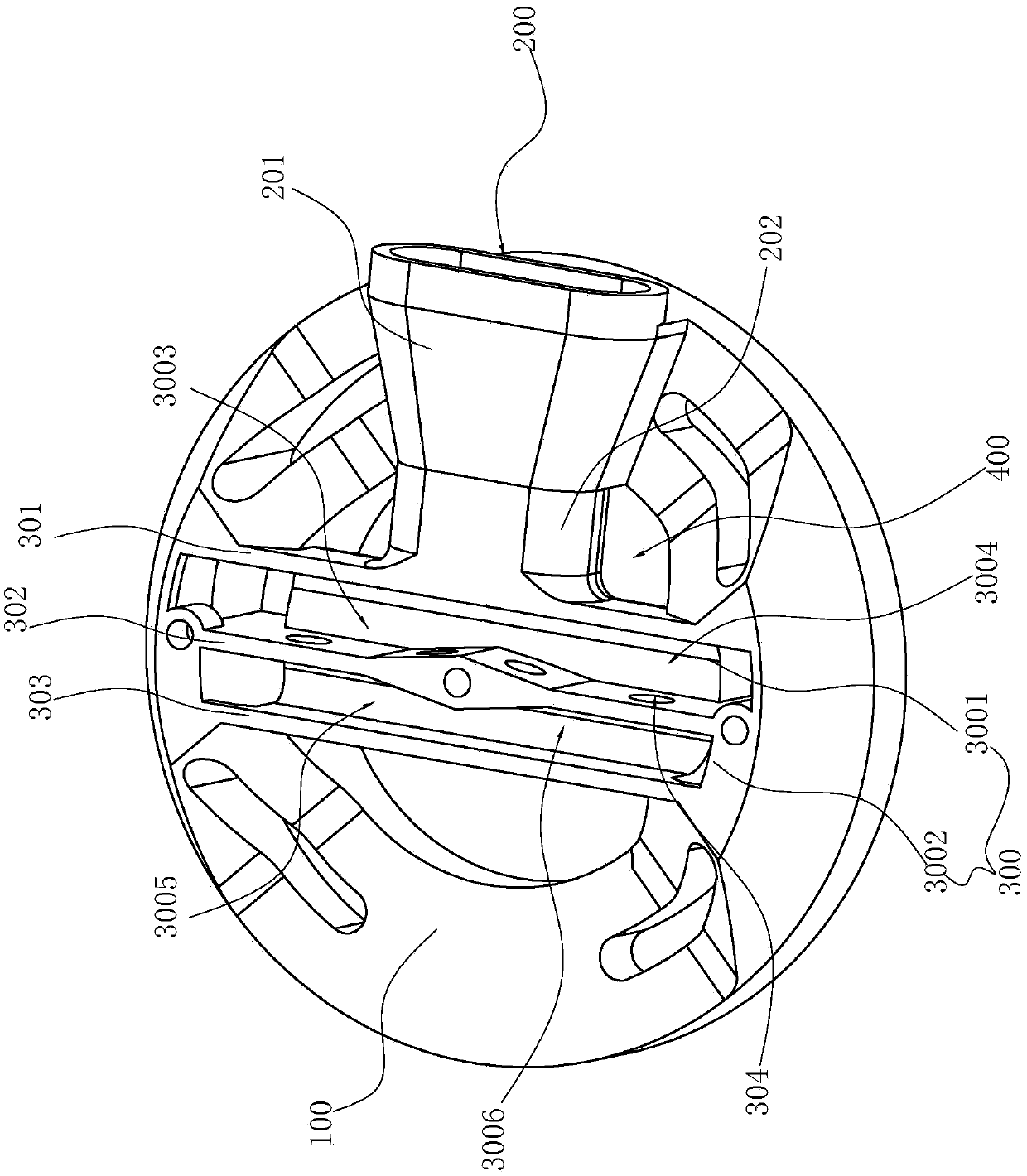

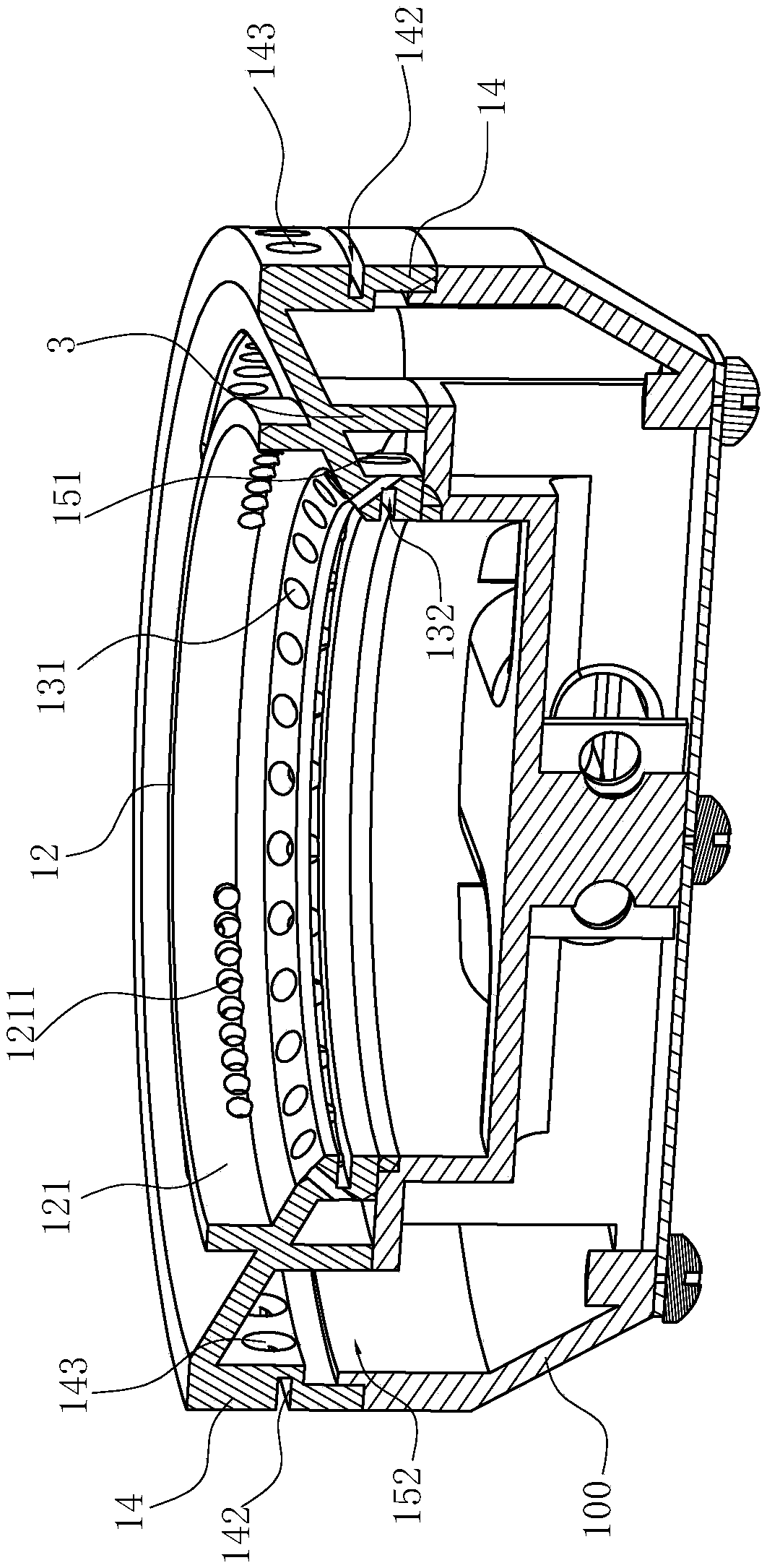

[0032] Such as Figure 1~6As shown, the burner used in the gas stove includes a base 100, the base 100 has an injection tube 200 arranged at the bottom of the base 100, arranged on the base 100, and between the base 100 The fire cover 1 that forms a relatively independent gas mixing chamber 15, and is arranged at the bottom of the base 100 and runs through the central position of the base 100 longitudinally, including a gas channel that communicates with the gas mixing chamber 15 and the injection pipe 200 300, in order to form a central fire and a peripheral fire in the fire cover 1 of the burner, the air mixing chamber 15 includes a first air mixing chamber 151 located on the inside and a second air mixing chamber 152 located on the outside, and the gas channel 300 includes The first partition 301, the second partition 302 and the third par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com