Jet combustion device for yarn singeing machine

A technology of burning device and singeing machine, which is used in singeing, textile and papermaking, fabric surface trimming, etc., can solve the problems of unreasonable structure, unstable flames, large and small flames, and large flame effects, so as to improve the quality and efficiency, less free carbon particles, high flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

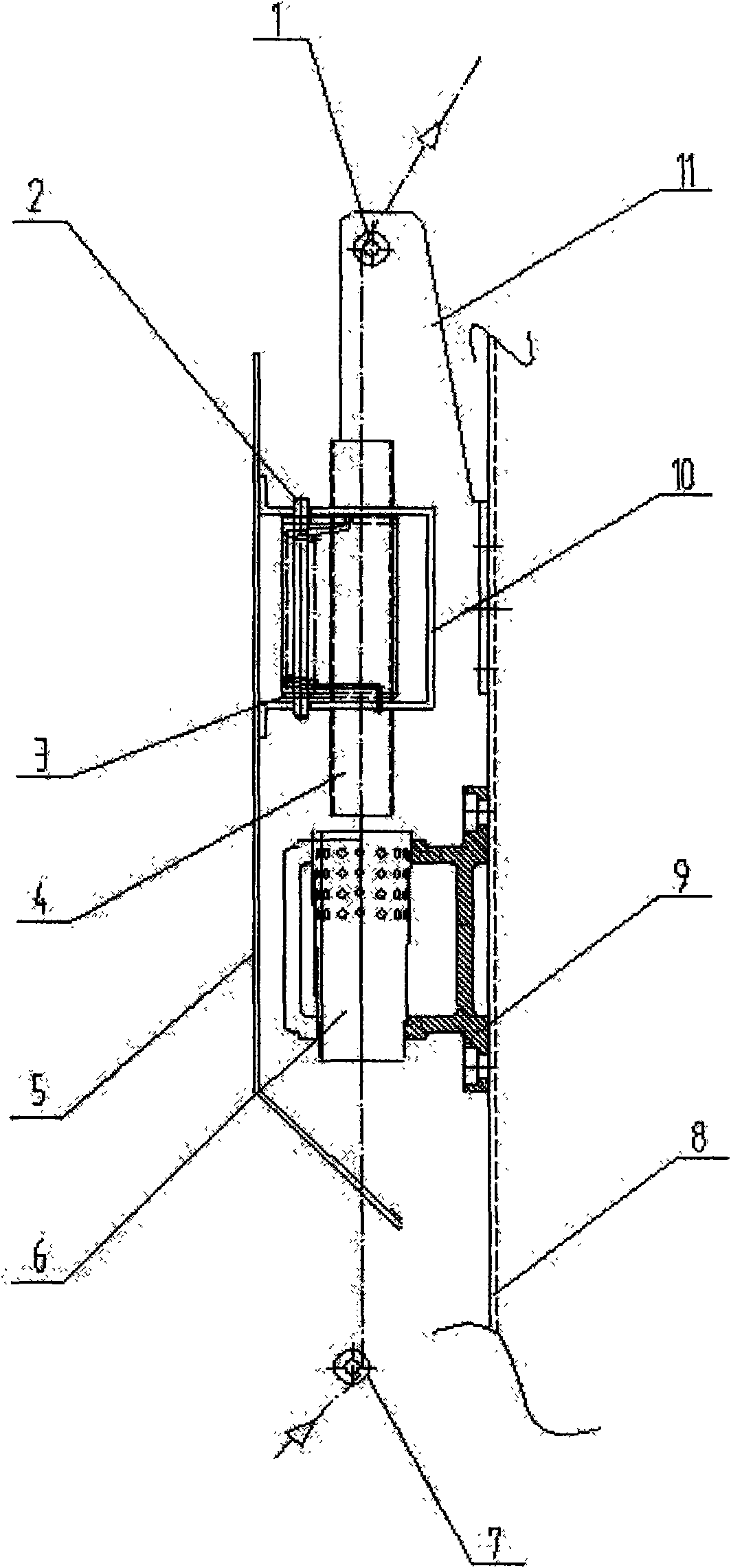

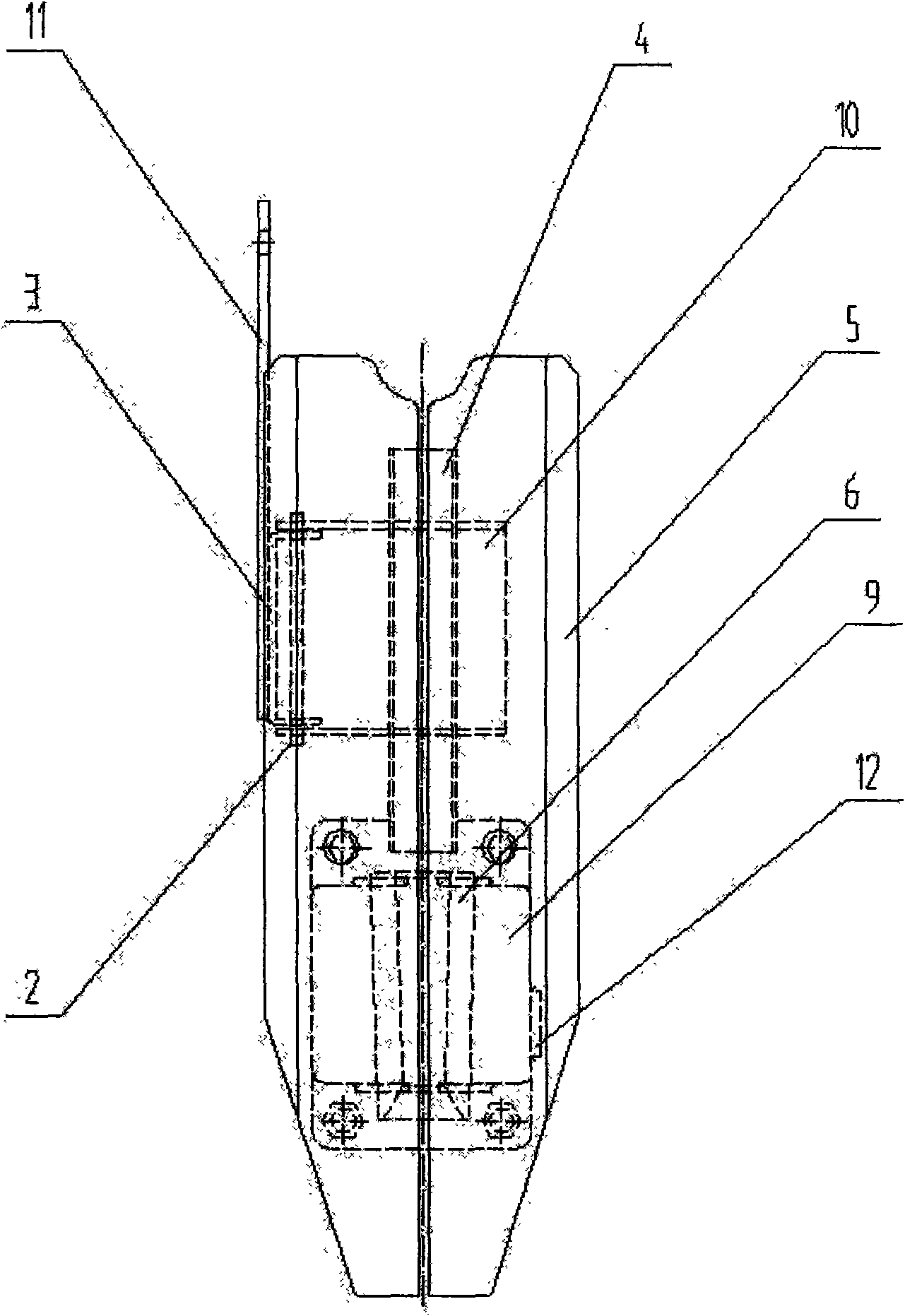

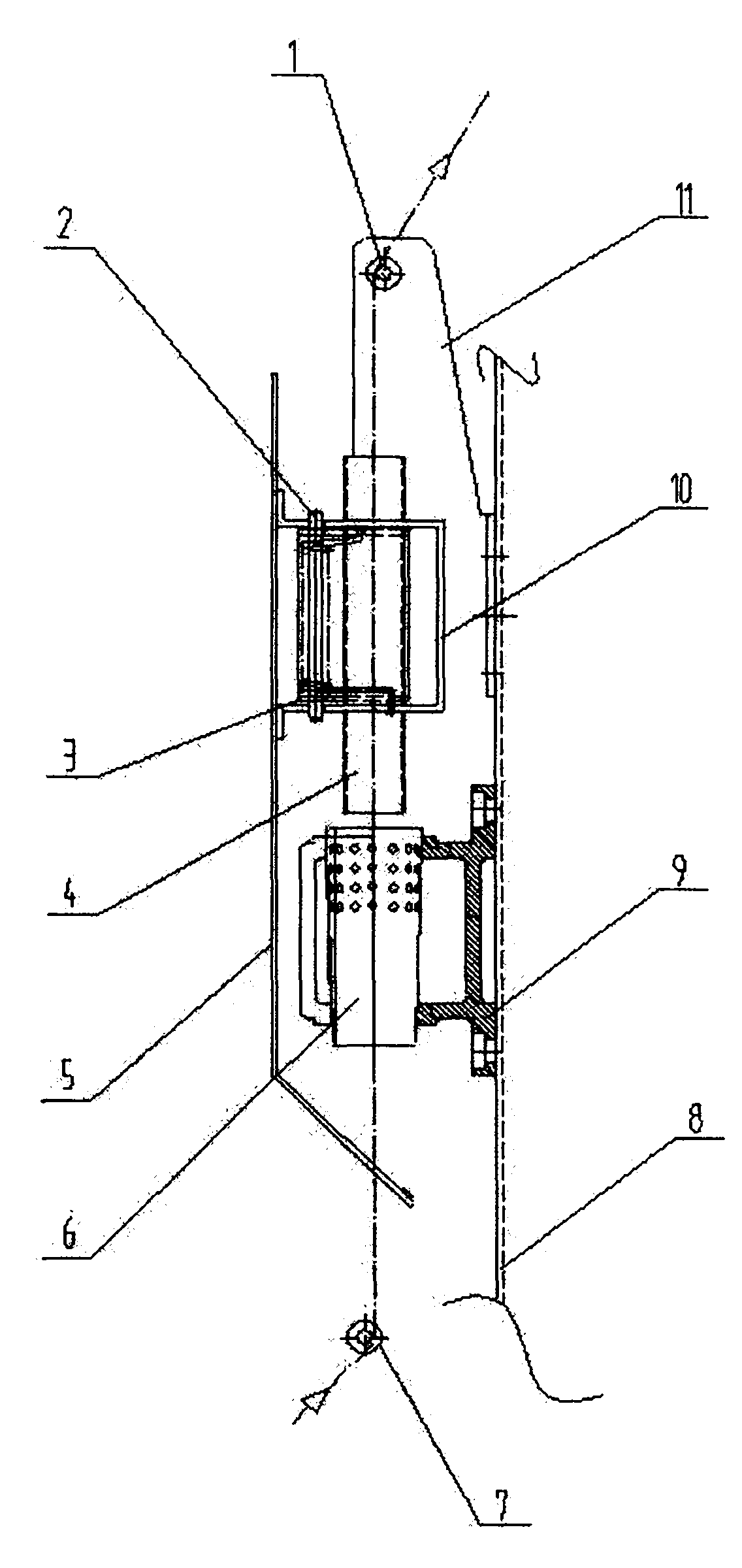

[0017] like figure 1 , figure 2 Shown:

[0018] The injection type combustion device of the yarn singeing machine, the air supply support 9 is a shell structure with a cavity inside, and the middle wall has a Morse taper that penetrates up and down, and a taper fitting is installed in the middle of the air supply support 9 The fire distributor 6, the center of the fire distributor 6 is a combustion channel for yarn singeing in the up and down direction, the cross section of the combustion channel is circular, and a strip is arranged on the front of the air supply support 9 and the peripheral wall of the fire distributor 6 The slit through up and down is used as the yarn inlet and outlet passage of the air supply support 9 and the fire distribution device 6, and the ventilation combustion holes arranged radially are arranged on the circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com