Effect-enhanced serial nozzle two-phase flow ejector and component refrigerating system thereof

An ejector and tandem technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of performance improvement that has not been reported in depth, the speed difference between vapor and liquid phase is large, fluid vapor, liquid Due to the large difference in phase density and other problems, the effects of easy processing and popularization and application, high ejection efficiency and no moving parts are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

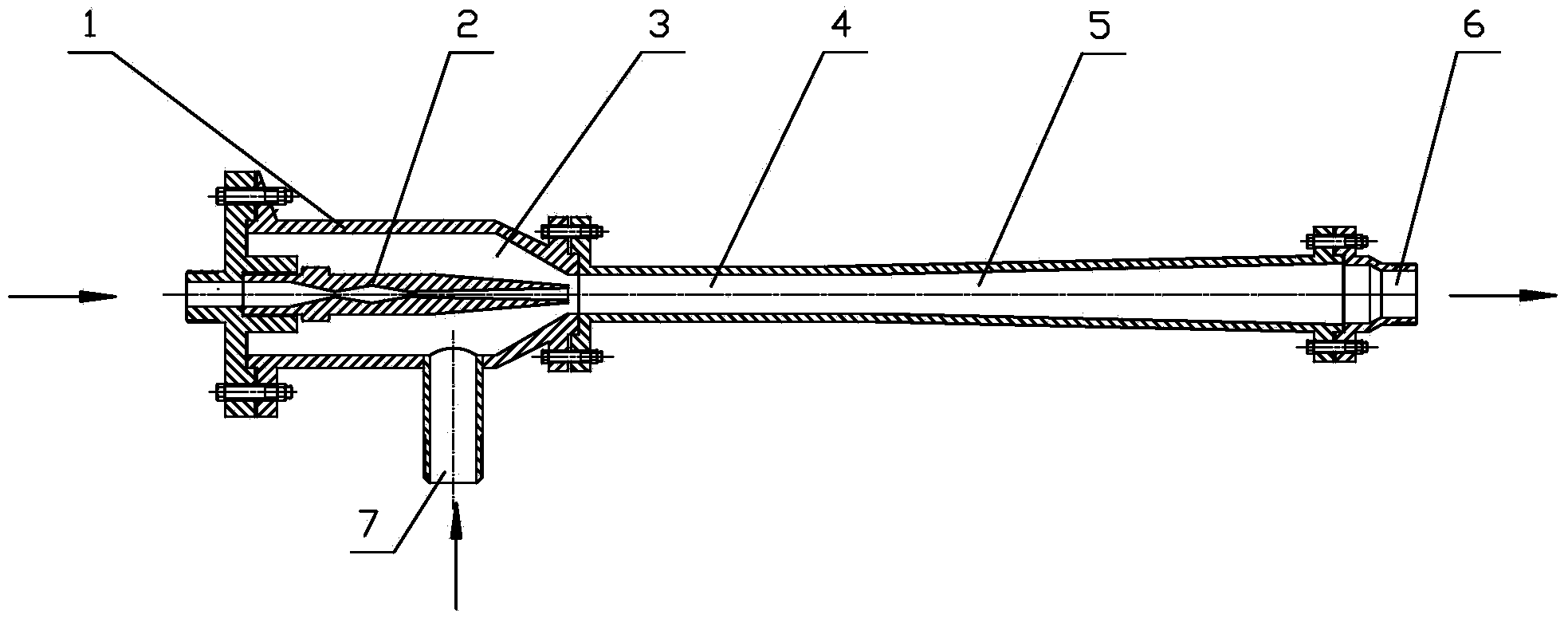

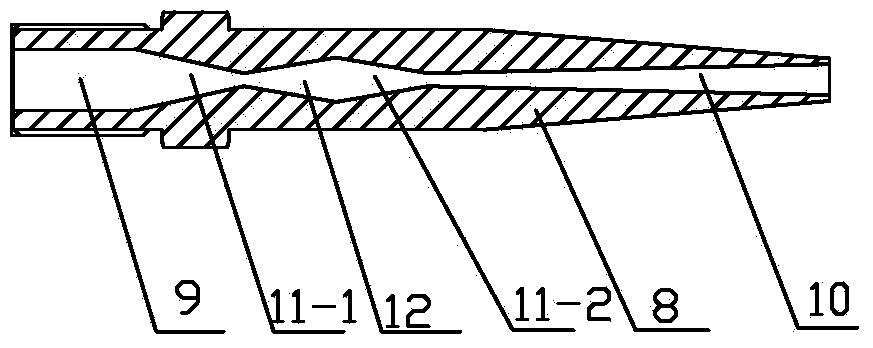

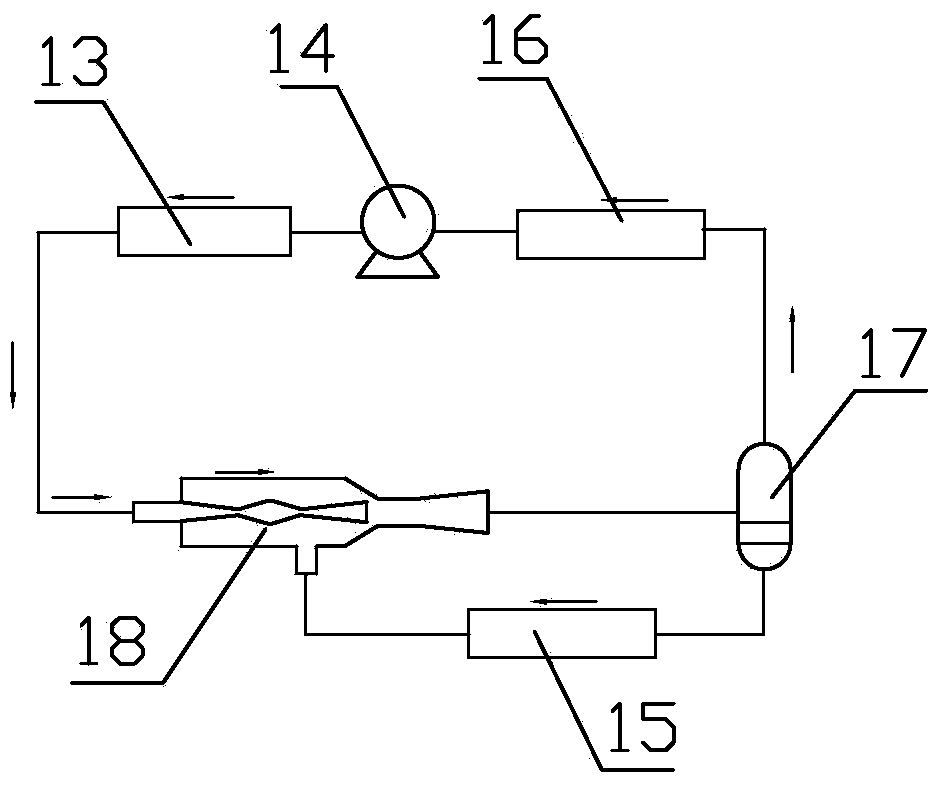

[0022] The schematic diagram of the synergistic tandem nozzle two-phase flow ejector of the present invention is as follows figure 1 with figure 2 As shown, it includes an ejector housing 1, an injection structure 2, a receiving chamber 3, a mixing chamber 4, a diffuser chamber 5 and an ejector outlet part 6, and the ejector housing 1 is provided with a main ejector inlet ( figure 1 at the left arrow in the middle) and the induced jet flow inlet 7. The injection structure 2 is installed inside the ejector housing 1, and the injection structure 2 includes an injection body 8. One end of the injection body 8 is an injection inlet port 9, and the other end is an injection outlet port 10. The inlet port 9 is connected to the main jet inlet, the main jet inlet port and the jet inlet port 9 are cylindrical flow channels, and the jet inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com