Combined cycle engine

An engine and annular technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems that the overall performance cannot be further improved, the technical requirements of turbine engines are demanding, and the components are complex, so as to improve combustion efficiency and space combustion utilization. , improve thermodynamic efficiency and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

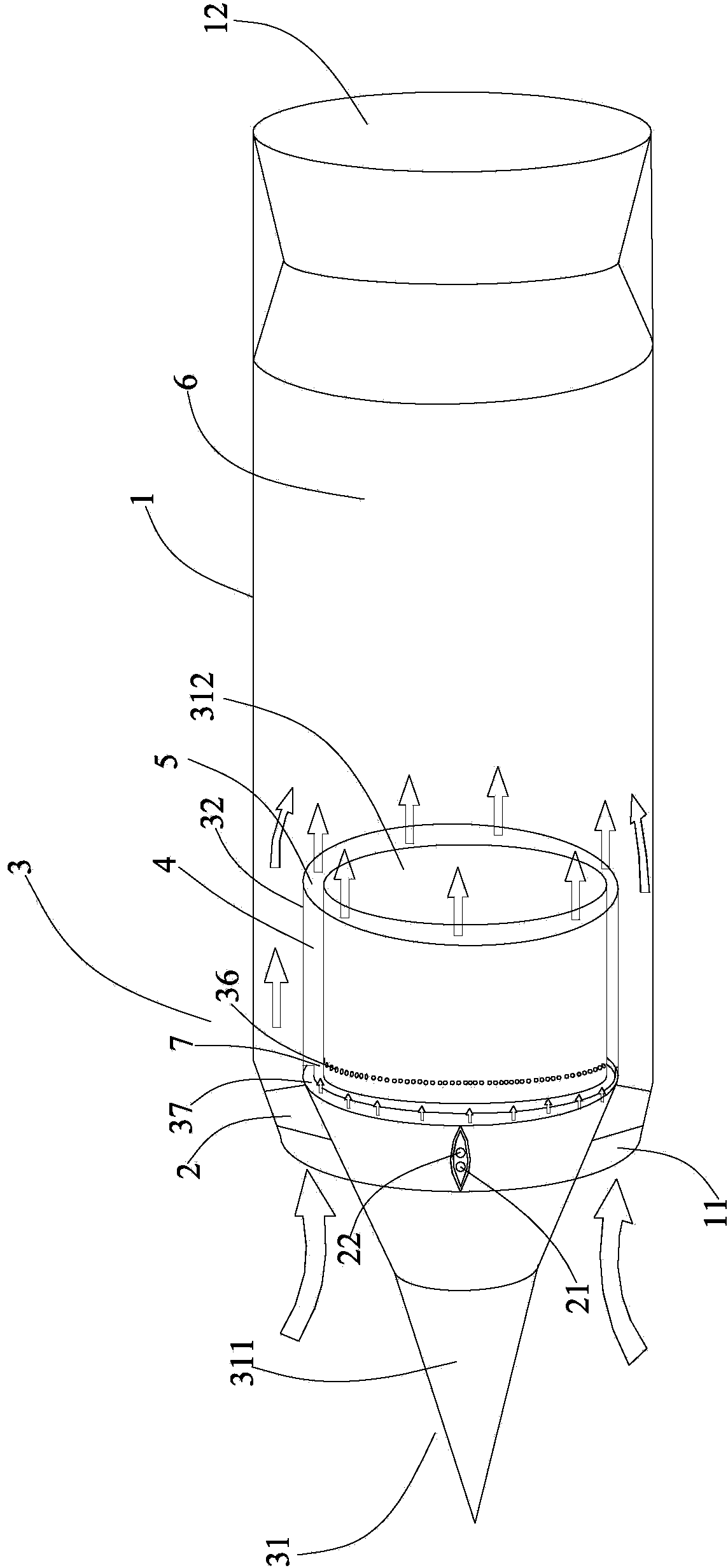

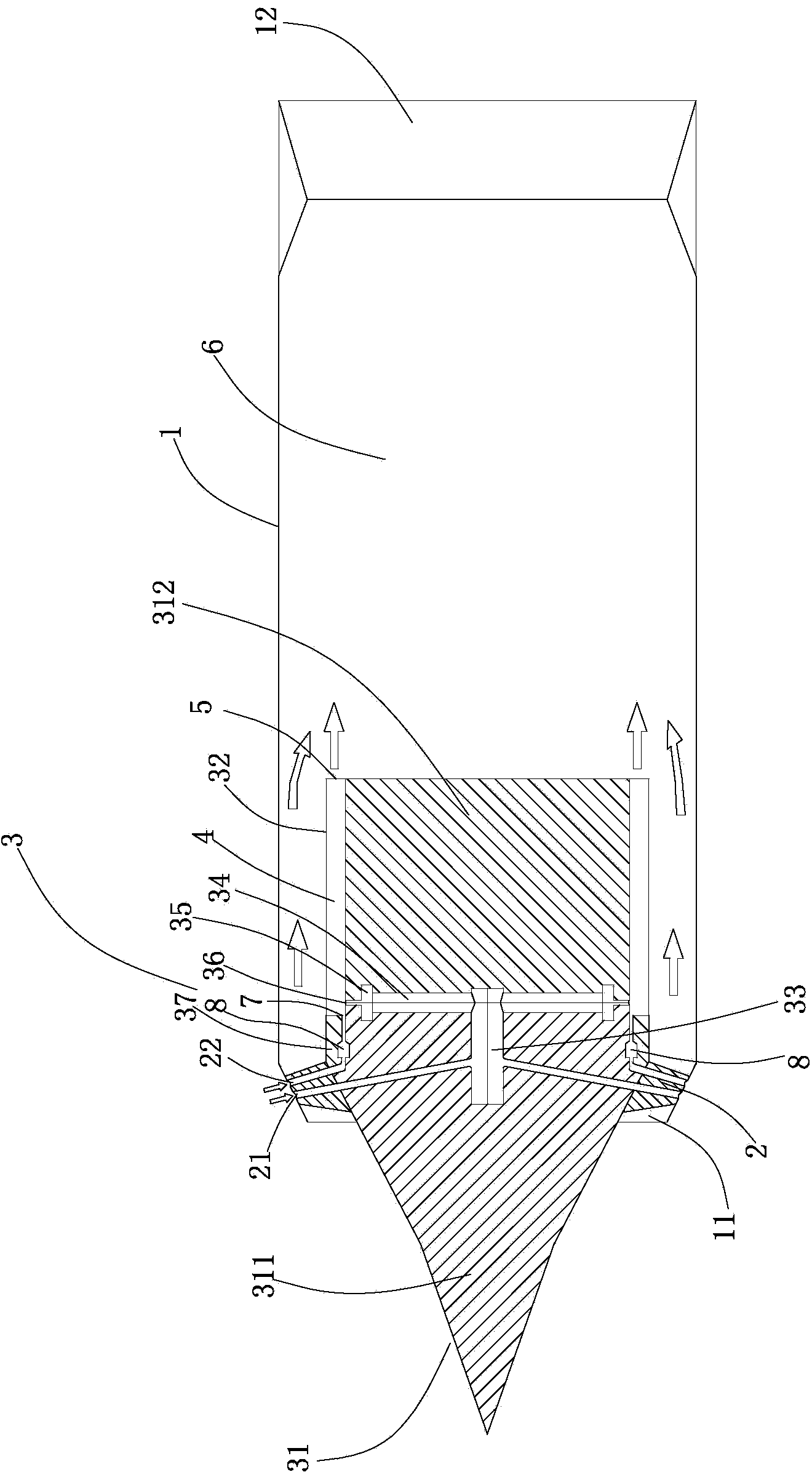

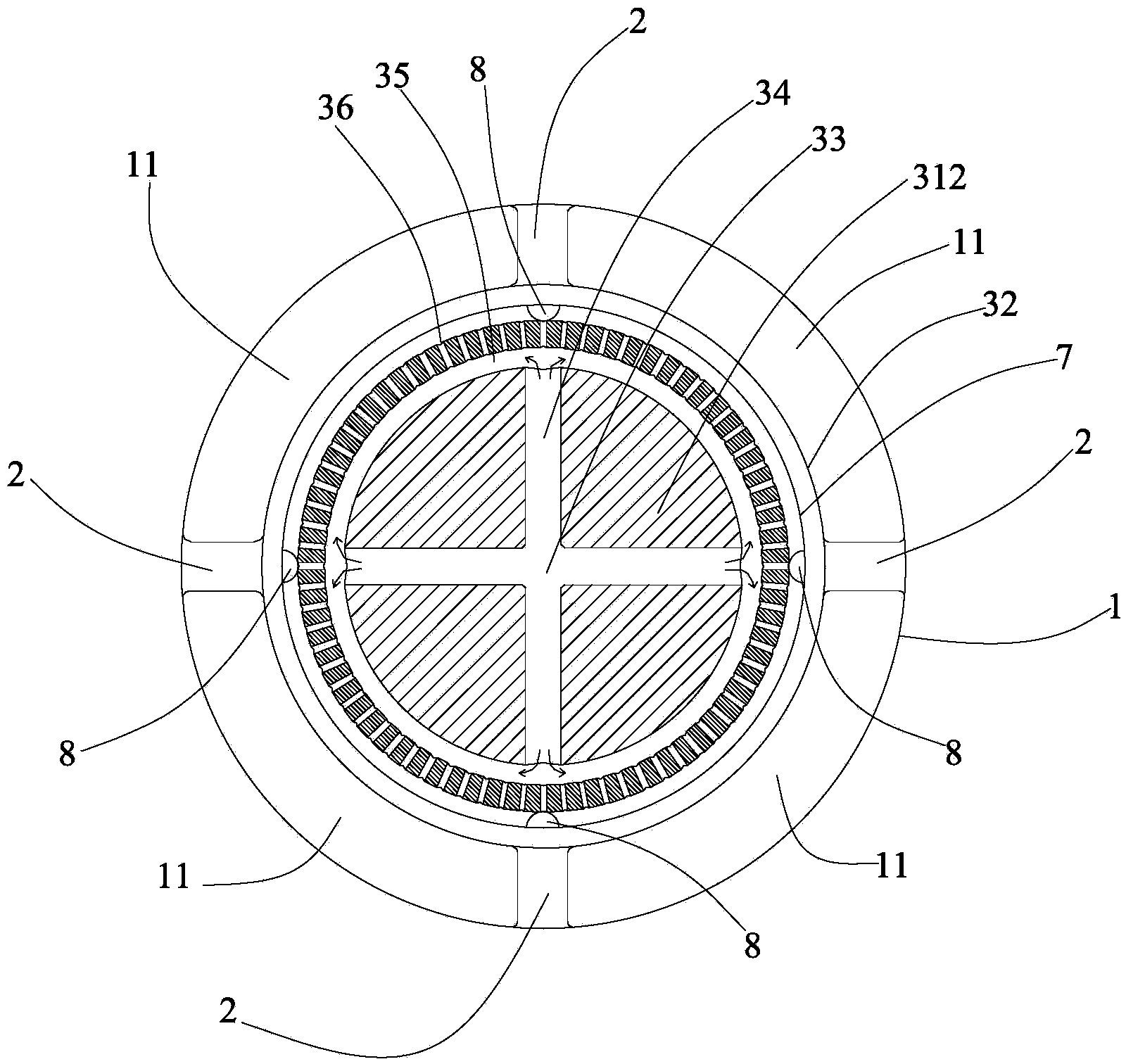

[0029] The combined cycle engine according to the present invention will be described in detail below with reference to the accompanying drawings.

[0030] refer to Figure 1 to Figure 3 , The combined cycle engine according to the present invention includes: a casing 1; a fixed guide column 2; and a continuously rotating detonation engine 3 as an ejection device.

[0031] The casing 1 is provided with: an air inlet 11 arranged at the front end of the casing 1 , which is annular and communicates with the external atmosphere; and a supersonic nozzle 12 arranged at the rear end of the casing 1 .

[0032] The fixed guide column 2 is provided with: a fuel inlet 21, which is arranged on the outer surface of the fixed guide column 2, and communicates with an external fuel supply device (not shown); and an oxidant inlet 22, which is arranged on the outer surface of the fixed guide column 2, It is connected to an external oxidant supply (not shown).

[0033] The continuously rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com