Efficient slotted multi-nozzle enhancing mixing ejector

An ejector and multi-nozzle technology, applied in the field of ejectors, can solve the problems of total pressure loss, increased length of mixing chamber, low ejection efficiency, etc., so as to reduce manufacturing difficulty, reduce exhaust noise, and improve ejection The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

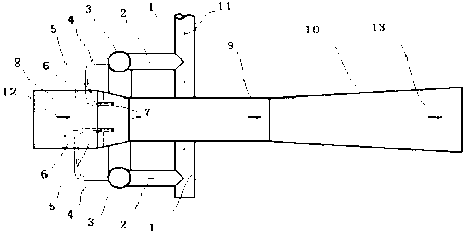

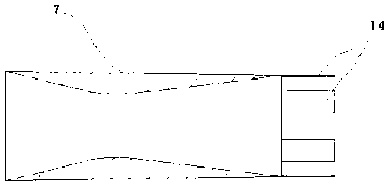

[0032] Such as figure 1 As shown, a high-efficiency slotted multi-nozzle enhanced mixing ejector, the device includes the following parts:

[0033] 1) Ejector intake main duct 1: This main duct introduces the active airflow that plays a driving role in the ejector;

[0034] 2) Injection intake diversion pipe 2: The diversion duct diverts the airflow injected into the main intake pipe 1 and introduces it symmetrically into the gas collection chamber 3;

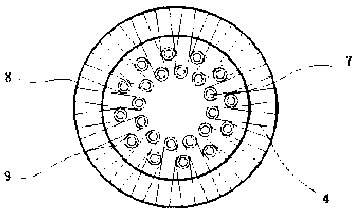

[0035] 3) Gas collection chamber 3: The gas collection chamber 3 stabilizes the air flow and supplies air to the injection nozzle 7;

[0036] 4) The air intake pipe 4 of the injection nozzle: the air intake pipe 4 of the nozzle draws air from the gas collection chamber 3 to supply air to the injection nozzle 7;

[0037] 5) Rear rectifying plate 5: the rear rectifying plate 5 is located downstream of the intake pipe 4 of the injection nozzle and is close to the intake pipe, and plays the role of rectification and support;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com