Surface tunneling miniature electron source, array thereof and implementation method of array

An implementation method and electron source technology, applied in the field of electronic science and technology, can solve the problems of difficult large-scale array integration and low emission efficiency, and achieve the effects of high electron emission efficiency, convenient processing, and easy large-scale array integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

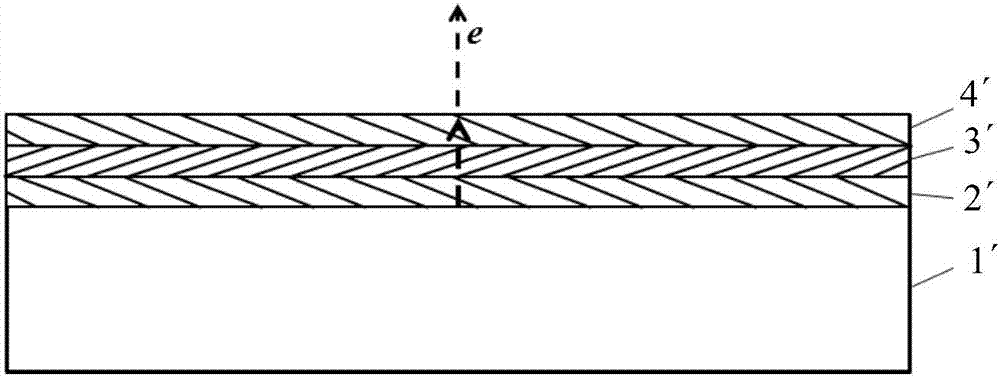

[0052] In this embodiment, the materials of the conductive region and the insulating region are embedded in the insulating substrate, and the upper surface thereof is flush with the surface of the insulating substrate.

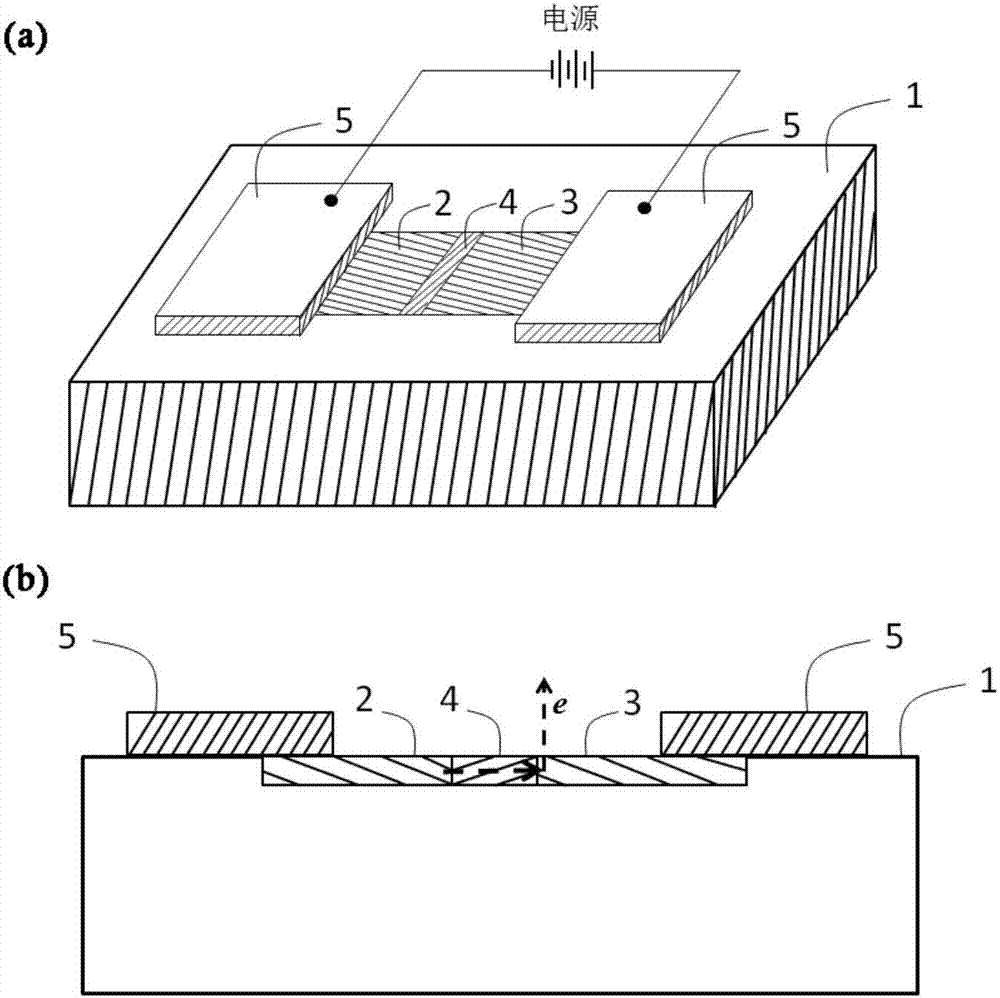

[0053] Such as figure 2 As shown, the surface tunneling miniature electron source constructed in this embodiment includes: an insulating substrate 1, conductive regions 2 and 3, an insulating region 4, and a pair of electrodes 5 for driving its electron emission.

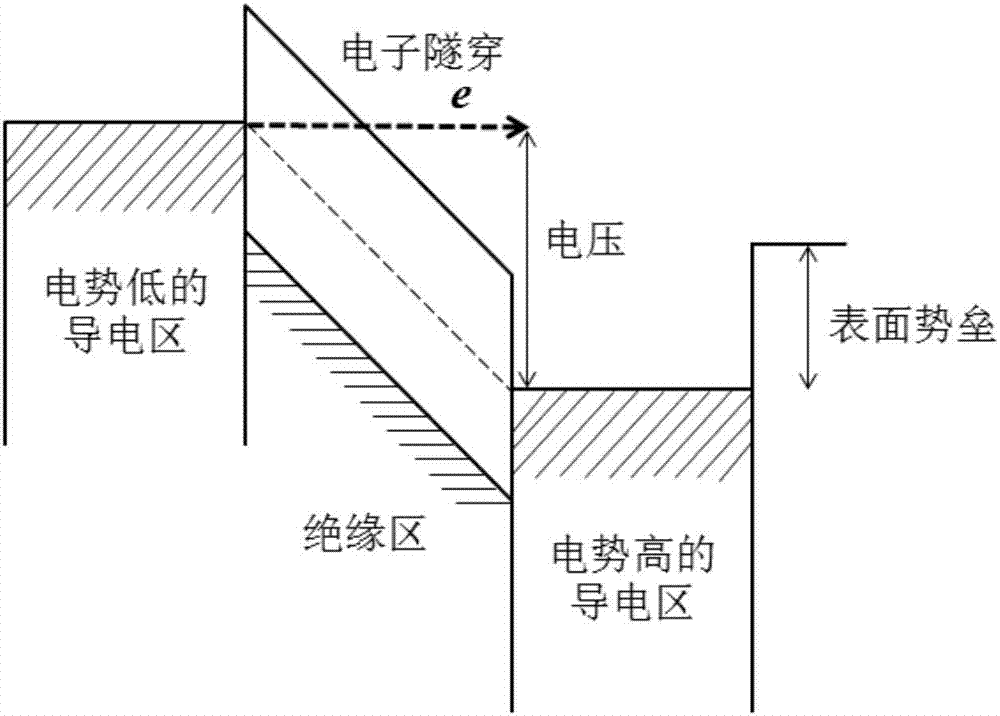

[0054] When a voltage is applied to the electrode pair 5, and the potential of the right electrode is high, electrons will tunnel from the conductive region 2 through the insulating region 4 and enter the conductive region 3, and finally vertically from the conductive region 3 close to the insulating region emitted from the surface of the substrate into vacuum.

[0055] Such as Figure 4 As shown, the surface tunneling miniature electron source array constructed in this embodiment includes: 2×5 ...

Embodiment 2

[0057] In this embodiment, the conductive region and the insulating region of the tunneling electron source are obtained by resistively switching the resistive material film to form conductive filaments, and further breaking the conductive filaments.

[0058] Such as Figure 5 As shown, the surface tunneling miniature electron source constructed in this embodiment includes: a supporting substrate 1, a resistive material film 6 covering the surface of the substrate, a pair of electrodes 5, and conductive regions 2 and 3 formed by breaking conductive filaments , Insulation area 4.

[0059] When a voltage is applied to the electrode pair 5, and the potential of the right electrode is high, electrons will tunnel from the conductive region 2 through the insulating region 4 and enter the conductive region 3, and finally vertically from the conductive region 3 close to the insulating region emitted from the surface of the substrate into vacuum.

[0060] In this embodiment, the surf...

Embodiment 3

[0065] In this embodiment, the materials of the conductive region and the insulating region are located above the surface of the insulating substrate, and their lower surfaces are flush with the surface of the insulating substrate.

[0066] Such as Figure 6 As shown, the surface tunneling miniature electron source constructed in this embodiment includes: an insulating substrate 1, conductive regions 2 and 3, an insulating region 4, and a pair of electrodes 5 for driving its electron emission.

[0067] When a voltage is applied to the electrode pair 5, and the potential of the right electrode is high, electrons will tunnel from the conductive region 2 through the insulating region 4 and enter the conductive region 3, and finally vertically from the conductive region 3 close to the insulating region emitted from the surface of the substrate into vacuum.

[0068] In this embodiment, the surface tunneling miniature electron source is realized by the following steps:

[0069] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com