Method for statically casting membrane element

A casting method and membrane element technology, applied in the coating and other directions, can solve the problems such as loose and uneven epoxy resin layer, large mechanical wear of membrane components, noisy working environment, etc., saving labor costs, less workload, and casting effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

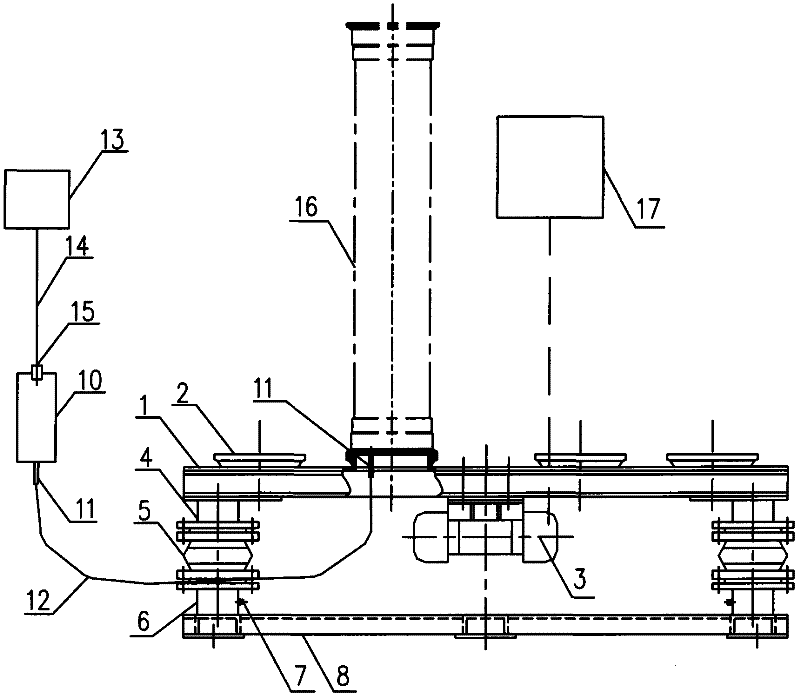

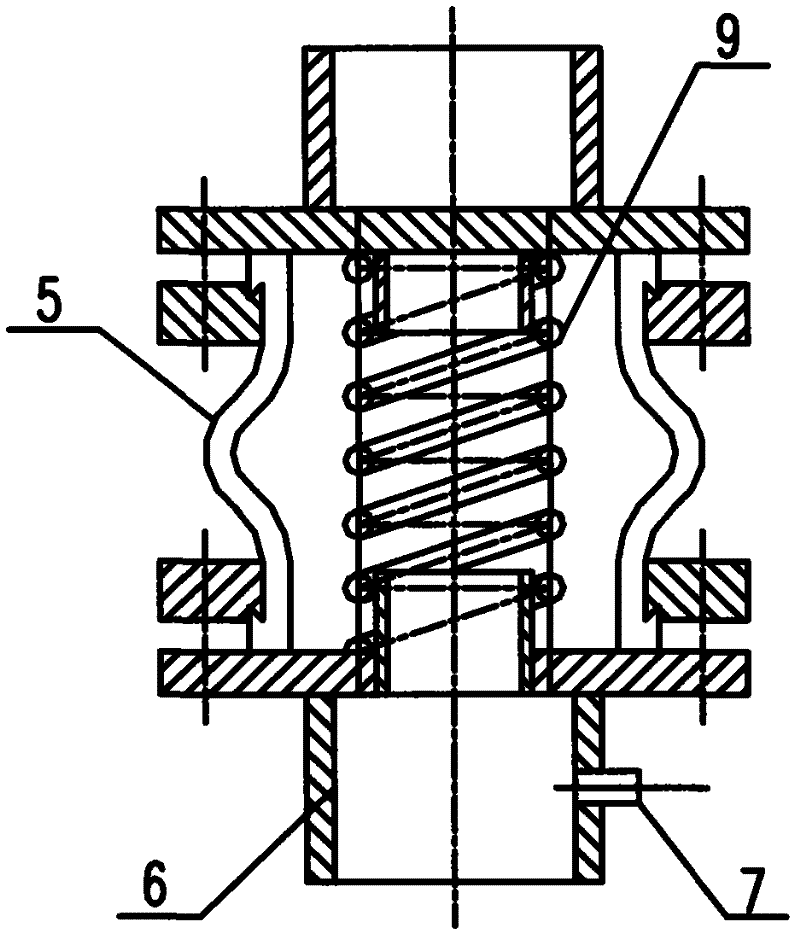

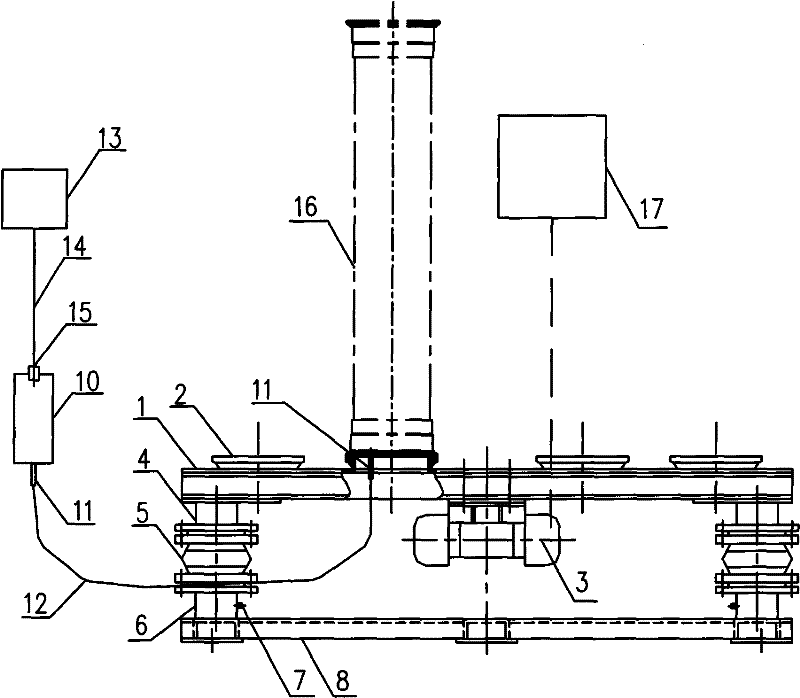

[0012] The process steps for realizing the static casting of the membrane element in this embodiment are as follows: first select the static casting device for the membrane element, assemble the membrane element 16 on the fixed ring 2 of the membrane shell, and tighten it with a clamp; Connect with the glue injection pot 10, and tie it tightly with a woolen rope or silk thread to ensure that it does not leak; then pour the epoxy resin with a good ratio into the glue injection pot 10, and firmly plug the rubber plug 15; turn on the power, open the compression The air system 13 allows compressed air to enter the glue injection pot 10 through the compressed air pipe 14, and the epoxy resin is slowly pressed to the glue injection nozzle 11 at the lower end of the membrane element 16 along the glue injection pipe 12, and then injected into the inside of the membrane element 16, The glue injection speed is 50-80mL / min; after all membrane elements 16 are glued and confirmed to be corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com