Surface passivating treatment method of spinel type manganese-based positive pole material

A spinel type, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of reducing the high temperature cycle stability of the material, difficult to control the thickness and uniformity of the coating layer, harmful to the environment and human body, etc. Achieve the effect of improving high temperature cycle performance, non-toxic and harmless human body, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

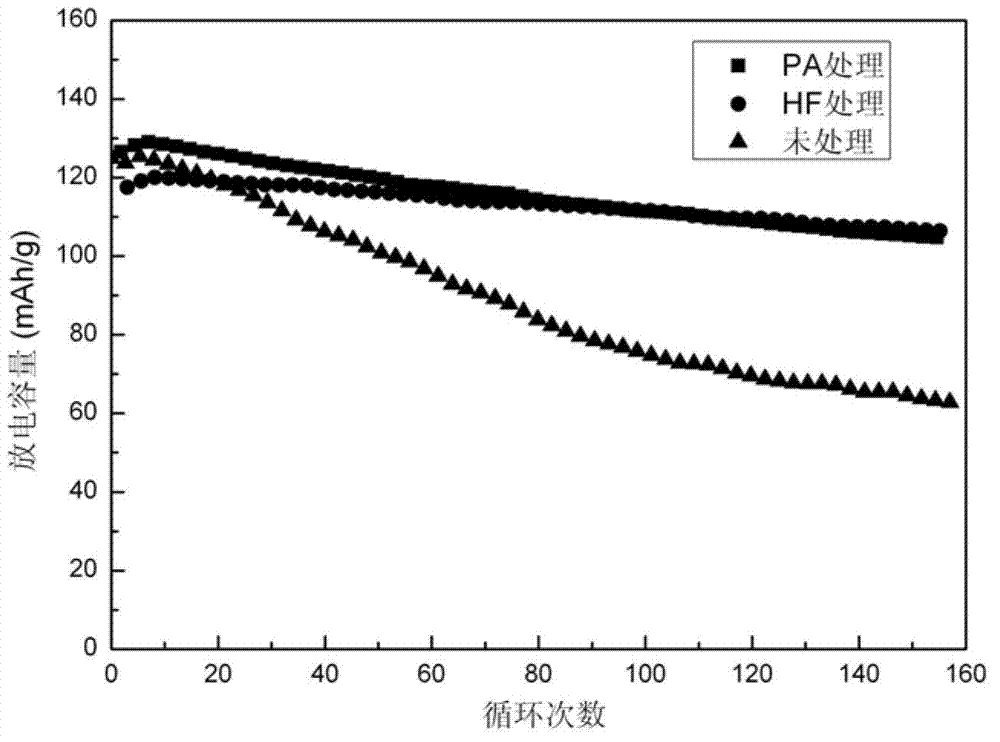

Embodiment 1

[0020] ⑴Weigh 2kg spinel LiNi 0.45 mn 1.45 Cr 0.1 o 4 The positive electrode material powder is placed in the container;

[0021] (2) Add 1000ml of HF solution with a mass fraction of 15% into the container at room temperature to make LiNi 0.45 mn 1.45 Cr 0.1 o 4 Soak the material powder in HF solution, stir continuously for 2 hours to carry out acid treatment, remove easily soluble Ni and Mn plasma on the surface of the material, and filter out the acid-treated LiNi 0.45 mn 1.45 Cr 0.1 o 4 Material;

[0022] (3) Use pure water as the washing liquid, and the LiNi filtered out by suction 0.45 mn 1.45 Cr 0.1 o 4 The material is washed repeatedly until the pH value of the washing solution is between 7-8;

[0023] (4) LiNi filtered out after washing 0.45 mn 1.45 Cr 0.1 o 4 The material was placed in an Ar atmosphere drying oven, and the LiNi 0.45 mn 1.45 Cr 0.1 o 4 The material is dried for 2 hours;

[0024] ⑸Take out the dried LiNi 0.45 mn 1.45 Cr 0.1 o...

Embodiment 2

[0026] ⑴Weigh 2kg spinel LiNi 0.45 mn 1.45 Cr 0.1 o 4 The positive electrode material powder is placed in the container;

[0027] (2) H at room temperature with a mass fraction of 85% 3 PO 4 (PA) solution 1000ml is added in the container, makes LiNi 0.45 mn 1.45 Cr 0.1 o 4 Material powder soaked in H 3 PO 4 (PA) solution, stirring continuously for 4 hours to carry out acid treatment, to remove easily soluble Ni and Mn plasma on the surface of the material, and to filter out the acid-treated LiNi 0.45 mn 1.45 Cr 0.1 o 4 Material;

[0028] (3) Use pure water as the washing liquid, and the LiNi filtered out by suction 0.45 mn 1.45 Cr 0.1 o 4 The material is washed repeatedly until the pH value of the washing solution is between 7-8;

[0029] (4) LiNi filtered out after washing 0.45 mn 1.45 Cr 0.1 o 4 The material was placed in an Ar atmosphere drying oven, and the LiNi 0.45 mn 1.45 Cr 0.1 o 4 The material is dried for 4 hours;

[0030] ⑸Take out the dr...

Embodiment 3

[0032] ⑴Weigh 2kg spinel LiNi 0.45 mn 1.45 Cr 0.1 o 4 The positive electrode material powder is placed in the container;

[0033] (2) H at room temperature with a mass fraction of 85% 3 PO 4 (PA) solution and 500ml of 15% HF solution, mixed thoroughly and added to the container to make LiNi 0.45 mn 1.45 Cr 0.1 o 4 Material powder soaked in H 3 PO 4 In the mixed solution of (PA) and HF, acid treatment was carried out by stirring continuously for 6 hours to remove easily soluble Ni and Mn ions on the surface of the material, and the acid-treated LiNi was filtered out. 0.45 mn 1.45 Cr 0.1 o 4 Material;

[0034] (3) Use pure water as the washing liquid, and the LiNi filtered out by suction 0.45 mn 1.45 Cr 0.1 o 4 The material is washed repeatedly until the pH value of the washing solution is between 7-8;

[0035] (4) LiNi filtered out after washing 0.45 mn 1.45 Cr 0.1 o 4 The material was placed in an Ar atmosphere drying oven, and the LiNi 0.45 mn 1.45 Cr ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com