Coal seam roof aquifer ground advanced pre-drainage method

A coal seam roof and water layer technology, which is applied in the field of coal mine water disaster prevention and control, can solve problems such as difficulty in ensuring continuous coal mine mining, poor working environment for workers underground, and injury to people, and achieve the effect of safe, efficient and continuous mining of coal seams and a friendly construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

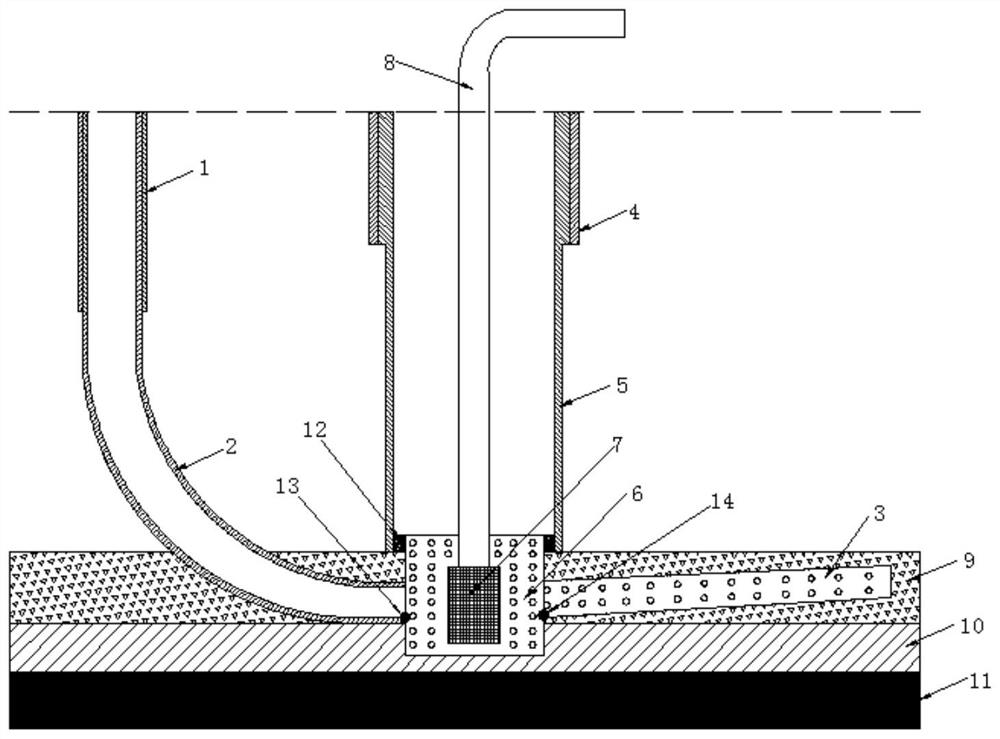

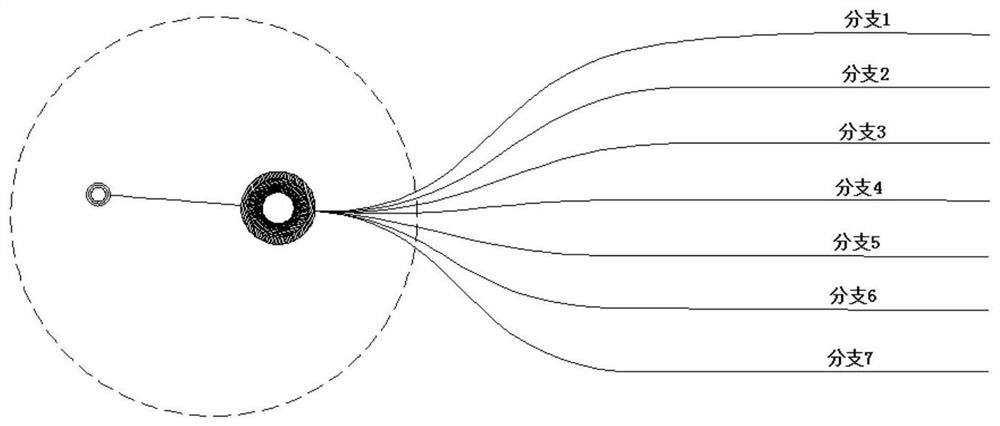

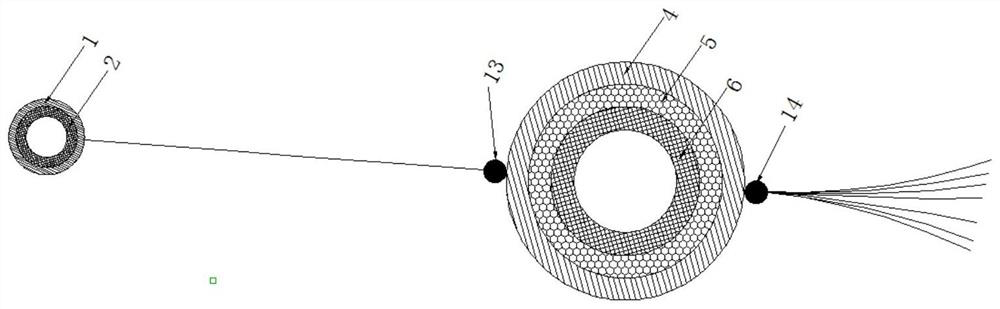

[0028] Such as figure 1 As shown, in this embodiment, a method for pre-draining water on the ground of the aquifer on the roof of the coal seam is to drill a ground multi-branch upward-inclining horizontal well and a large-diameter drainage well, and install a high-power, high-lift submersible pump in the large-diameter well. The roof-enriched water flowing through the multi-branch upward-dipping horizontal well three-opening screen pipe is discharged from the bottom of the large-diameter drainage well to the ground for use, so as to realize the pre-drainage of ground water in the coal seam roof aquifer.

[0029] The ground multi-branch upward-dipping horizontal well is designed with a three-cut well body structure. The first cut is designed to drill a Φ349.25mm drill bit into the stable bedrock for 5m, and the Φ273.05mm surface casing is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com