A mechanized waste-free mining method for deep metal deposits

A mining method and metal technology, applied in ground mining, mining equipment, earth cube drilling, etc., can solve the problems of low mining efficiency of deep metal mines, high cost of deep mining promotion, and pollution of the surface environment, so as to prevent surface pollution and safety Threat, safe and efficient continuous mining, high degree of mechanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0042] The invention provides a mechanized non-waste mining method for deep metal deposits.

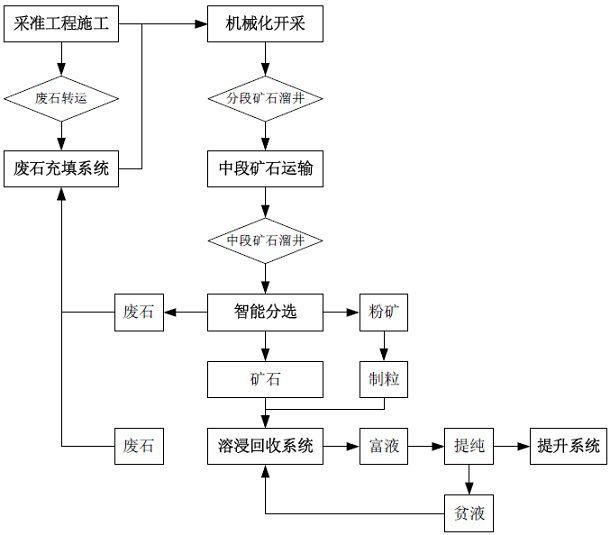

[0043] Such asfigure 1 As shown, the method includes the following steps:

[0044] S1: Stope design and mining construction:

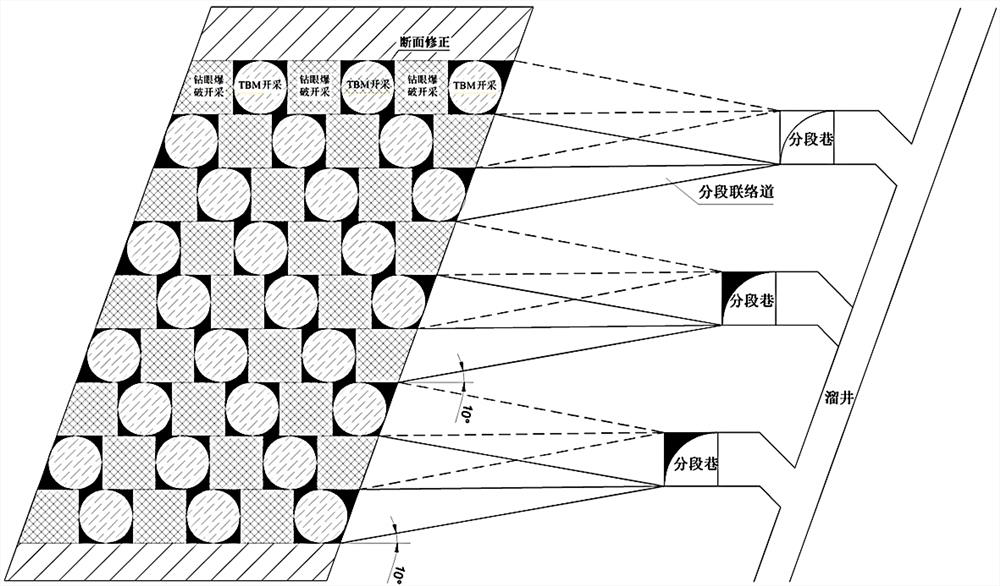

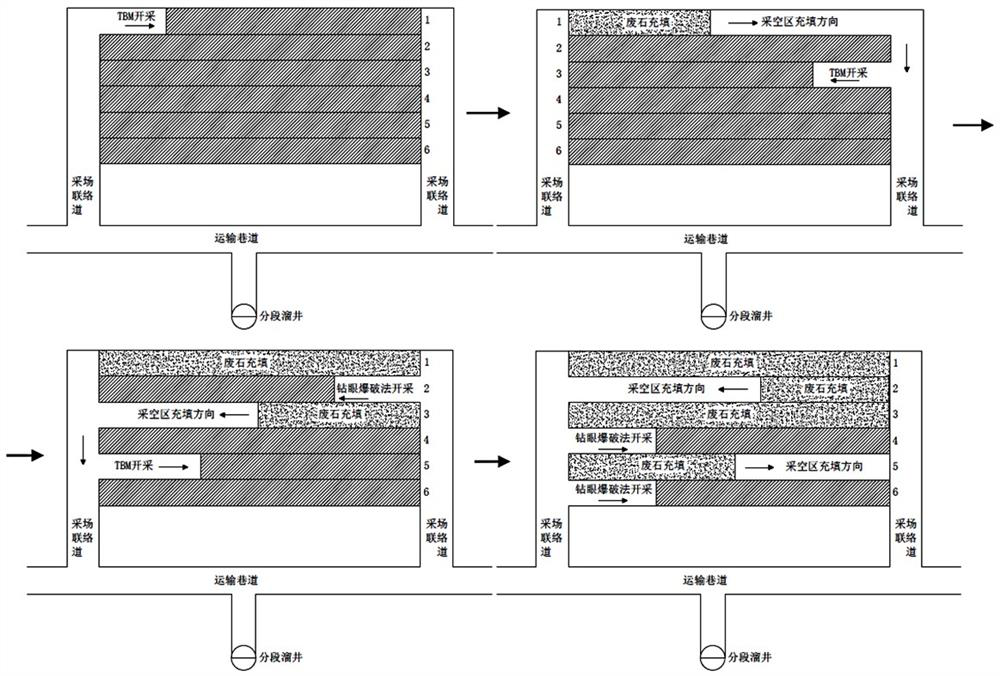

[0045] Mining is carried out along the direction of the ore body, and the stopes are arranged according to the thickness of the ore body. The number of stopes is an even number, and mining is carried out in a downward horizontal layering manner. Each section and middle section are constructed with a stope connection along both sides of each stope. There is no connecting road in the middle; ventilation shafts run through each middle section, and ventilation shafts are arranged at the footwall of each section, and air ducts are used for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com