Method for manufacturing colorful multilayer sheets

A multi-layer sheet, color technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. Good grip and friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The ingredients of the masterbatch described in the table were put into the cavities, and the hot-melt adhesive waste and the above-mentioned polyvinyl resin were put into the other cavities respectively. The materials in each cavity are extruded at the same time by the conventional co-extrusion method, and the color multi-layer sheet with a three-layer structure is prepared by embossing rollers.

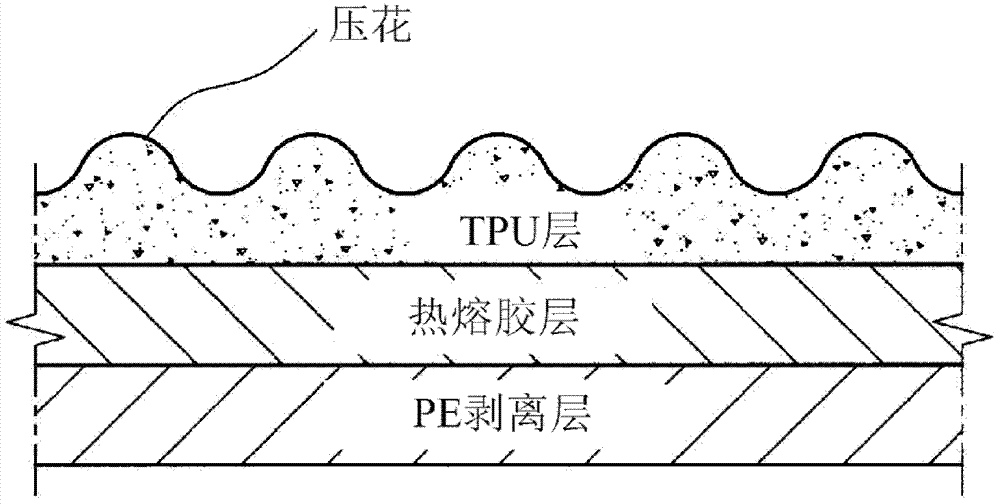

[0054] The color multi-layer sheet prepared by the above method in the present invention has the following properties: figure 1 The three-layer structure shown includes a bottom layer composed of a PE release layer, a hot melt adhesive layer formed on the PE release layer, and an embossed TPU layer on the hot melt adhesive layer. The hot melt adhesive layer is 200 microns thick, while the TPU layer is 150 to 200 microns thick.

[0055] Where the masterbatches in Table 2 were used instead of those in Table 1, the PE release layer and the hotmelt The subbing layer was formed ...

Embodiment 2

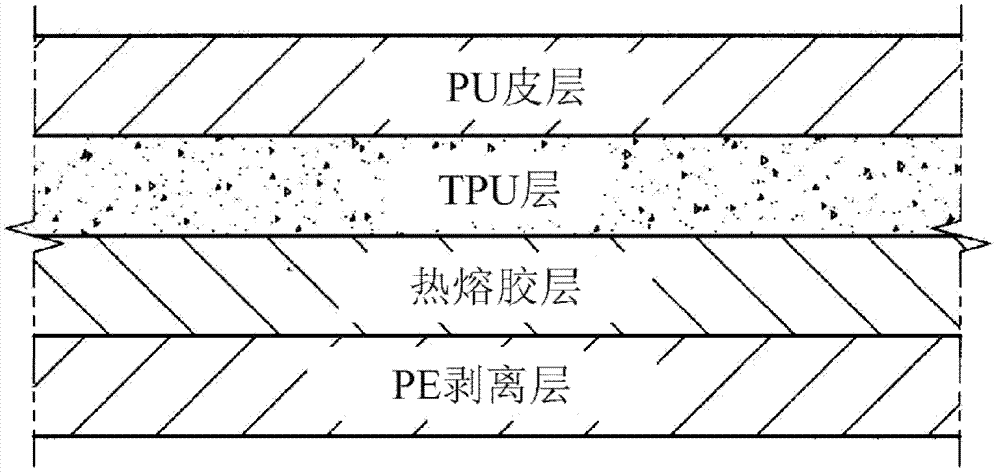

[0057] The colored multilayer sheet prepared in Example 1 having a PE release layer, a hot melt adhesive layer, and an embossed TPU layer was combined with PU through a conventional lamination method. Here, the PU is preferably multi-colored, but may also be monochromatic in some cases.

[0058] In other words, when the PU as figure 2 Laminated on the surface of the embossed TPU layer, the embossed portion of the TPU layer is pressed down to increase the bonding area and thus provide a bond between the TPU layer and the PU. Strong adhesion.

[0059] In this way, the PE release layer, the hot melt adhesive layer, the TPU layer, and the PU skin layer form a complete multi-color sheet of the present invention in order from bottom to top.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com