Internal mixer rotor sealing device

A technology of rotor sealing and internal mixer, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of wear and leakage, small maintenance, low maintenance cost, etc., to improve quality, small maintenance, maintenance low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

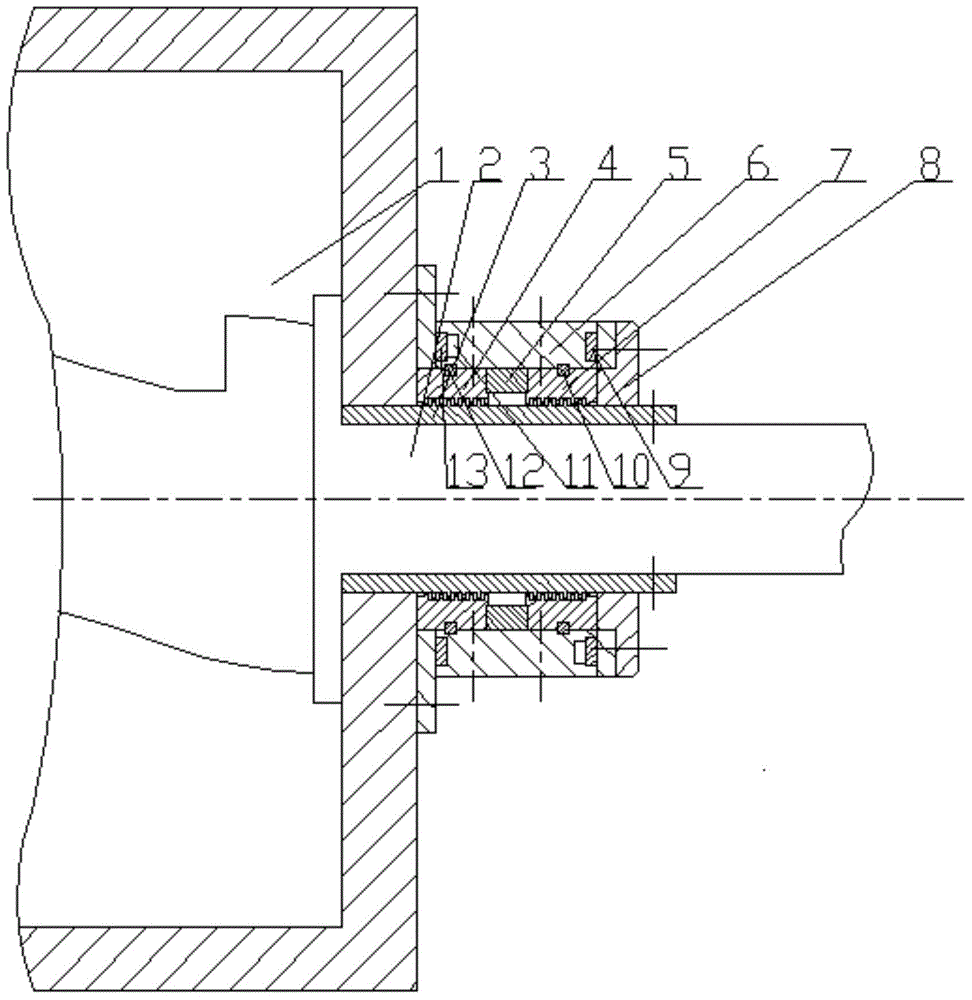

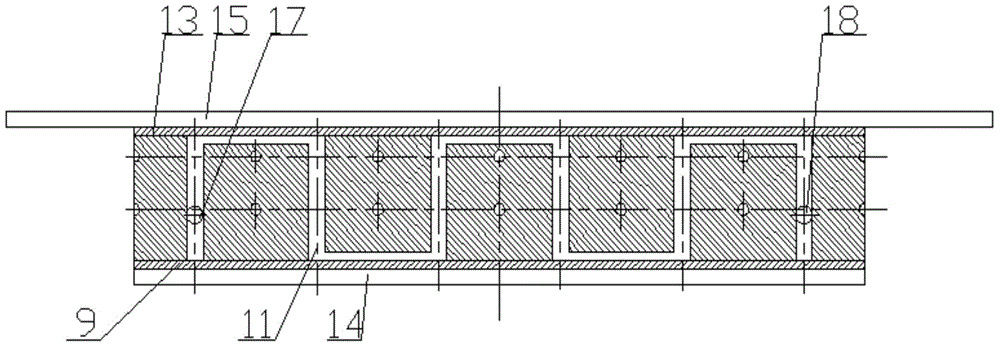

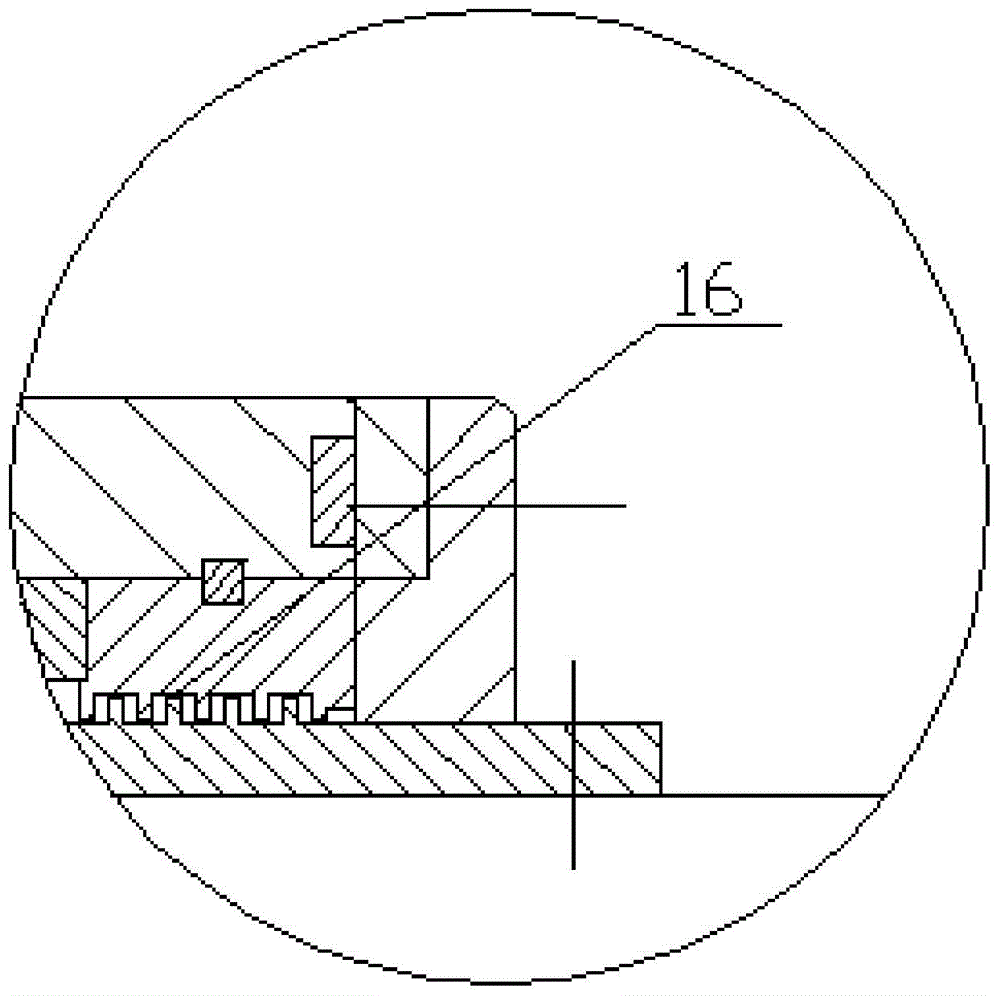

[0012] The rotor sealing device of the internal mixer involved in this embodiment is integrally arranged on the exposed rotor shaft 2 of the internal mixing chamber 1, and its main structure includes a threaded shaft sleeve 3, a No. Ⅰ pole shoe 4, a permanent magnet 5, a housing 6, and a No. Ⅱ pole Boot 7, end cover 8, Ⅰ sealing cover 9, Ⅰ O-ring 10, cooling channel 11, Ⅱ O-ring 12, Ⅱ sealing cover 13, end flange 14, fixed flange 15 , Magnetic medium 16, liquid inlet 17 and liquid outlet 18, of which No. Ⅰ pole piece 4, No. Ⅱ pole piece 7 and shell 6 are all symmetrically split structures. The threaded shaft sleeve 3 is tightly sleeved on the rotor by screw fixing On the shaft 2, one end of the shell 6 sheathed on the threaded sleeve 3 is fixedly connected to the outer wall of the mixing chamber 1 by screws, and the other end of the shell 6 is fixedly connected with an end cover 8 by screws, and the inner cavity wall of the shell 6 No. Ⅰ pole piece 4 and No. Ⅱ pole piece 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com