Automatic rail deviation correction device and automatic rail deviation correction method for AGV trolley

A technology of correction device and trolley, applied in two-dimensional position/flight control, vehicle position/route/height control, motor vehicle and other directions, can solve problems such as production stagnation and affect production efficiency, avoid injuries and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

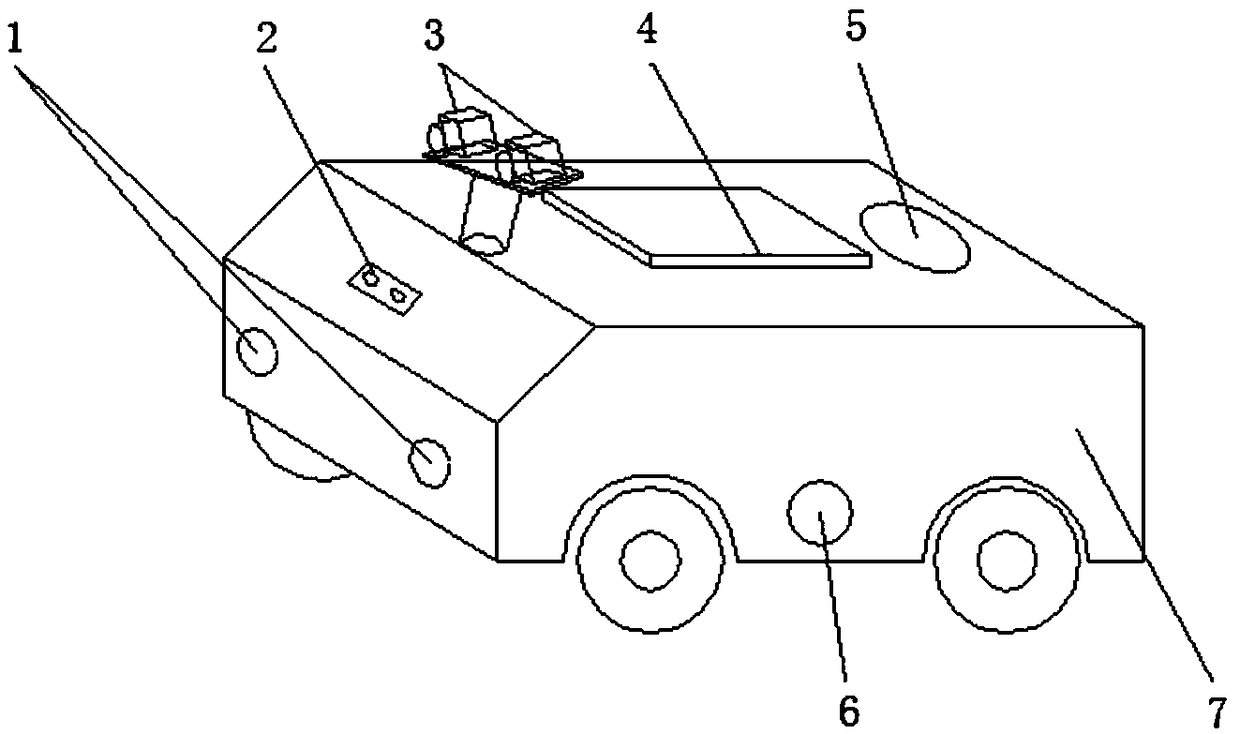

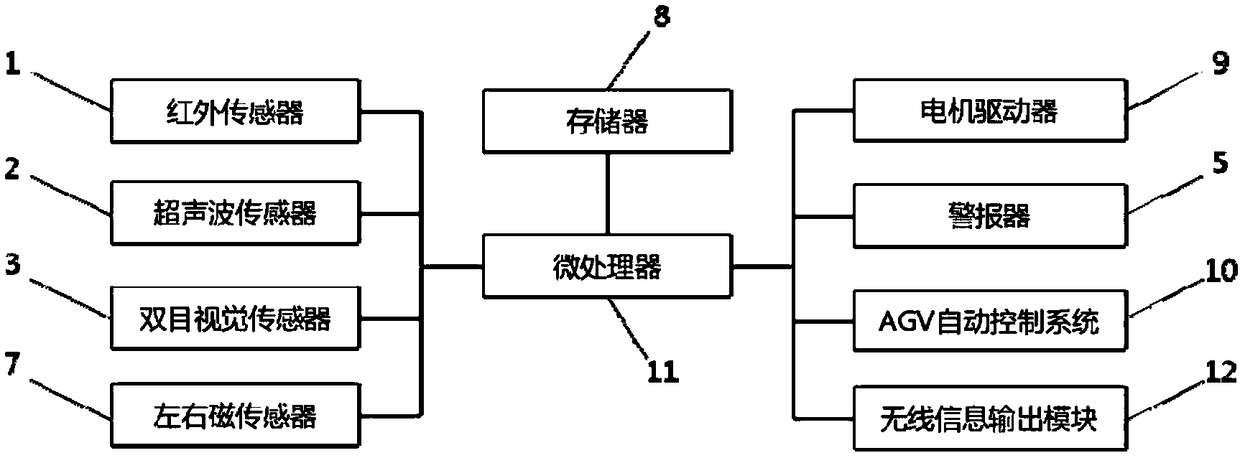

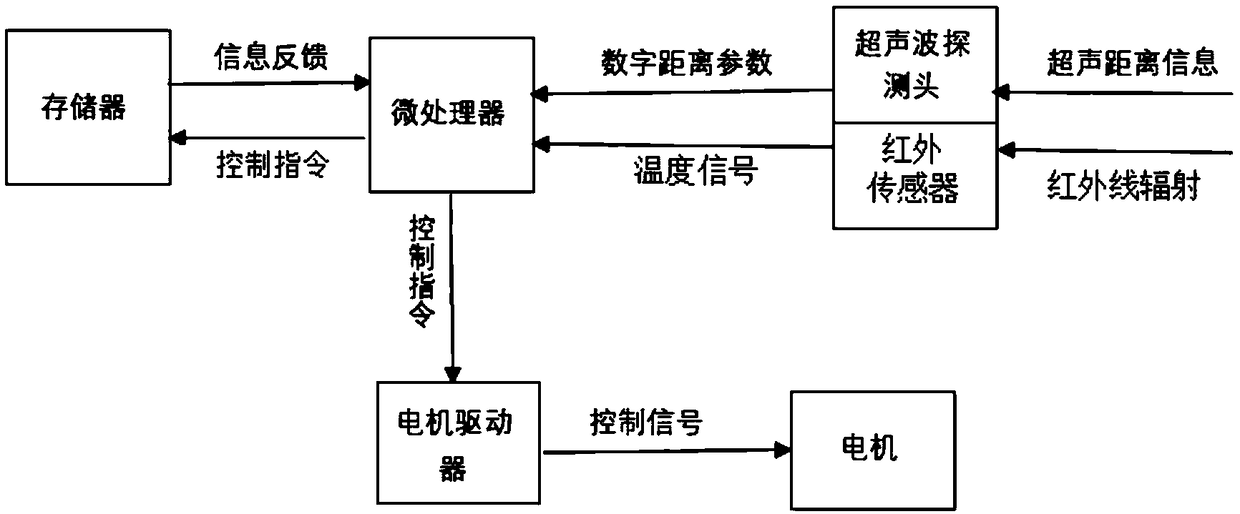

[0019] The present invention installs an automatic off-track correction device on the AGV trolley to ensure personal safety and improve production efficiency. It is equipped with a binocular vision sensor, which automatically captures images and compares them with existing images in the memory, so that it can track accurately and automatically. In addition, infrared sensors and ultrasonic sensors are installed. When someone appears in front of the AGV car, an alarm will be issued and the brakes will be applied to ensure personal safety. When the safety is determined, the AGV car will run again. This can be used to ensure personal safety and the safety of factory logistics and transportation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com