A closed type tea steaming and pressing device

An autoclave device and closed technology, which are applied in the fields of closed tea autoclave devices and tea steaming furnaces, can solve the problems of manual timing of the steaming time, and achieve the effects of saving manpower, reducing labor intensity, and being friendly to the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

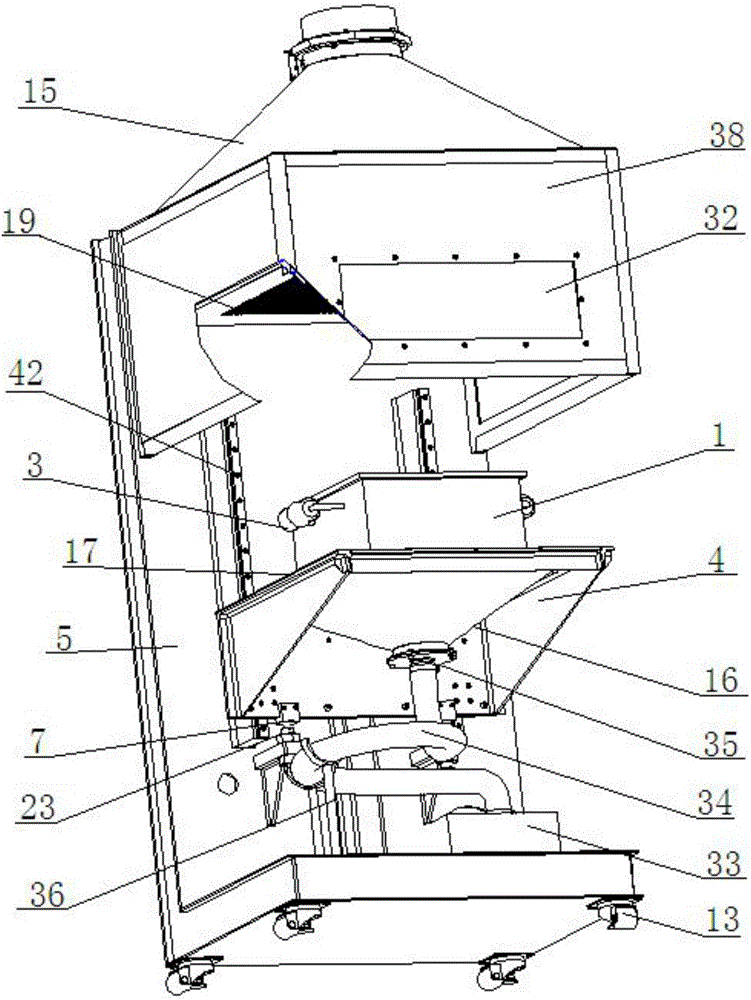

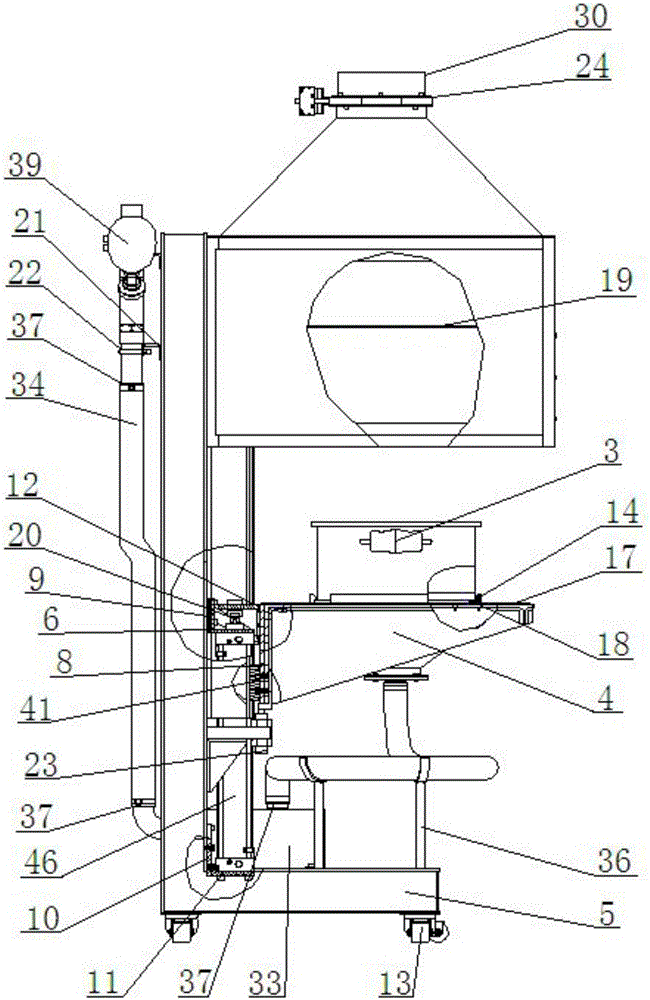

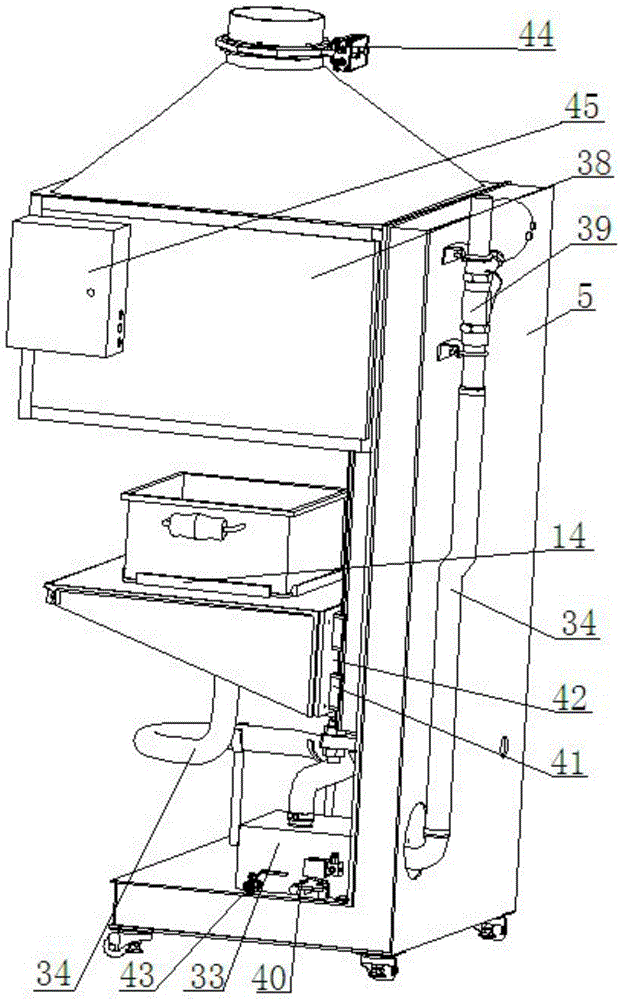

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] see Figure 1-Figure 3 , a closed tea autoclaving device, comprising a frame 5, an exhaust hood 15, a movable support 4, a tea steaming box 1, a water collection box 33, a pipeline 34, a rotating cylinder 44, two sets of sliders 41, an electric control box 45 and a cylinder 46. The frame 5 is an L-shaped frame, and the frame 5 includes a side plate and a bottom plate. The upper end of the side plate inner side of frame 5 is fixed with upper fixed mount 38, is provided with top plate 19 in described upper fixed mount 38; The punching plate is made, and the upper side of the top plate 19 can be reinforced with a welded rib plate. An exhaust hood 15 is arranged on the top of the upper fixing frame 38 , and a switch body is arranged on the top of the exhaust hood 15 . The switch body is provided with an upper flange 30 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com