Angle-adjustable multilayer linear vibrating screen for engineering plastic granules

A technology of linear vibrating screen and engineering plastics, applied in the direction of filter screen, cleaning methods and utensils, solid separation, etc. Simple equipment structure and friendly working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

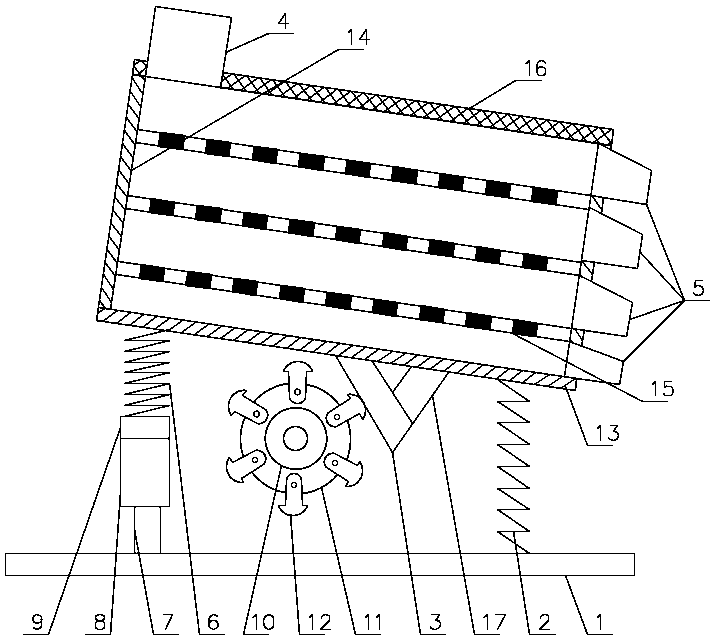

[0017] like figure 1 As shown: the angle-adjustable multi-layer linear vibrating screen for engineering plastic material particles in this embodiment includes an installation base 1, one side of the installation base is connected to the screen body through two return springs 2, and the other side of the installation base One side is connected to the other end of the sieve body through two height-adjustable springs. The center of the bottom of the sieve body is provided with an exciting plate 3 at an angle of 45° to the bottom of the sieve body. The base A vibrator for beating the vibrating plate is installed on the top, the upper part of the sieve body has a feed port 4, and the bottom of the inclined side has a discharge port 5.

[0018] In the angle-adjustable multi-layer linear vibrating screen for engineering plastic material particles described in this embodiment, the height-adjustable spring includes a spring seat and a spring body 6 arranged on the spring seat, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com